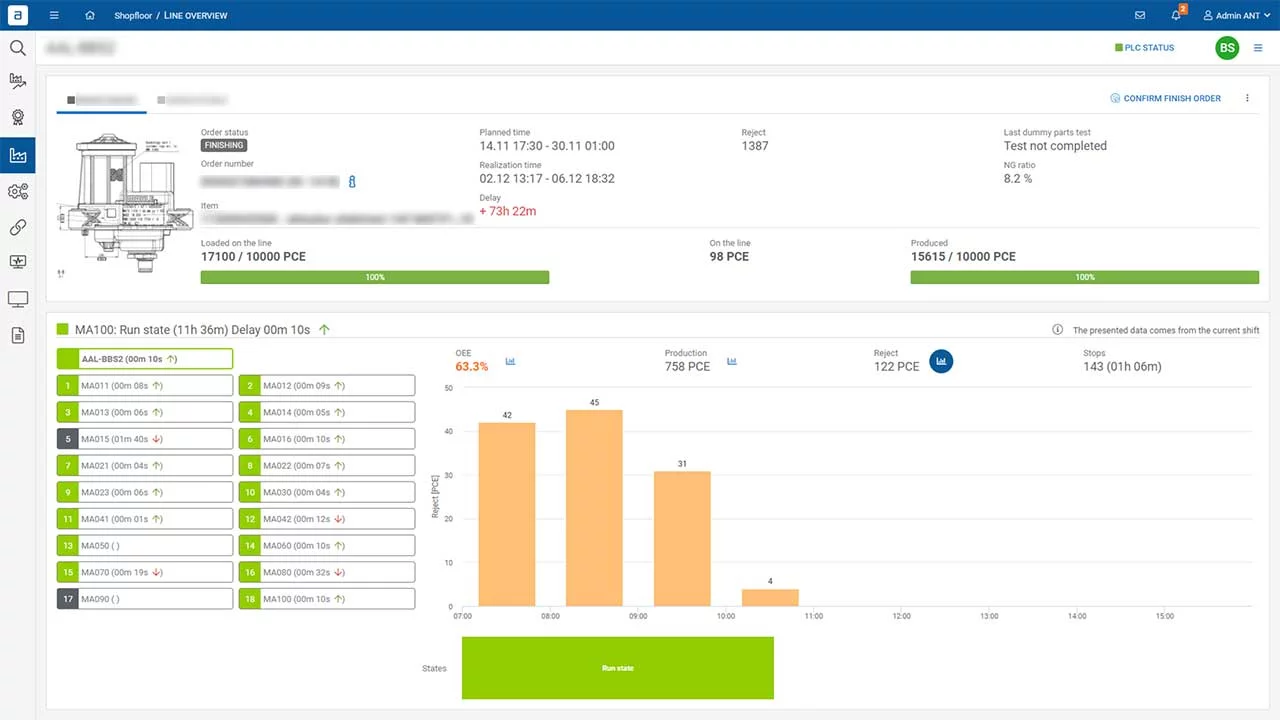

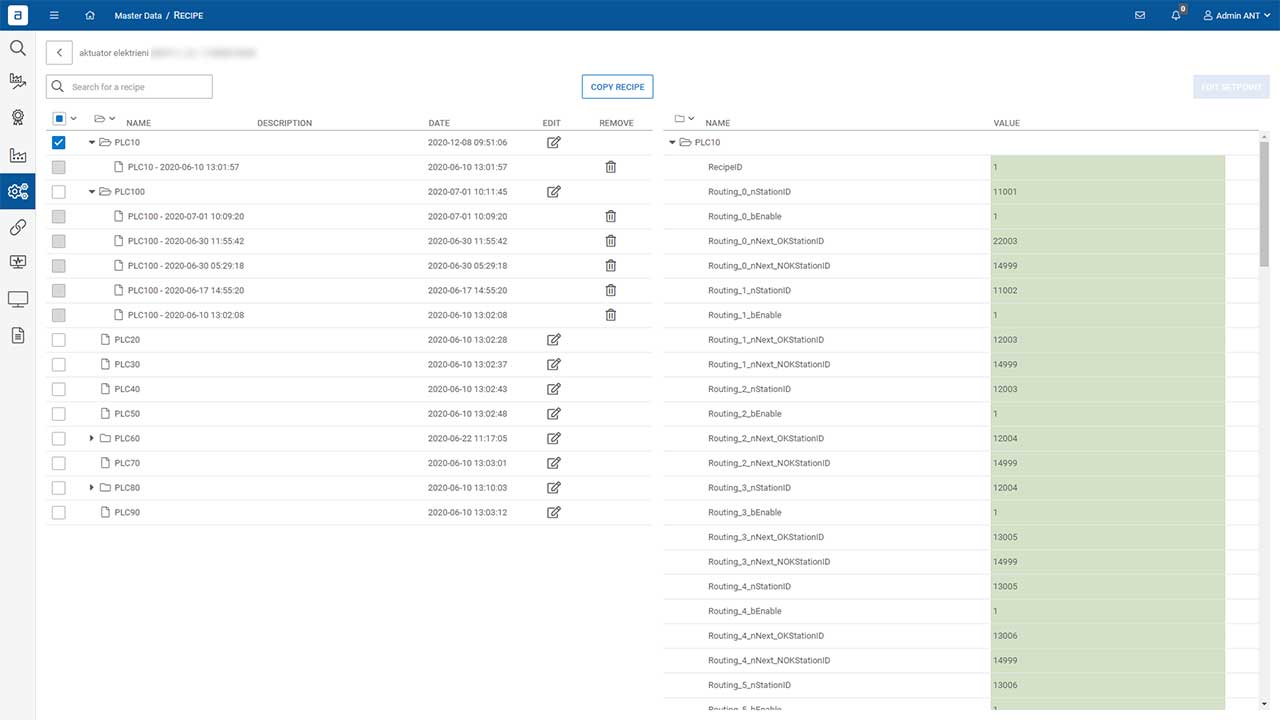

Electronic Batch Record – Automation and Paper Elimination in Pharma

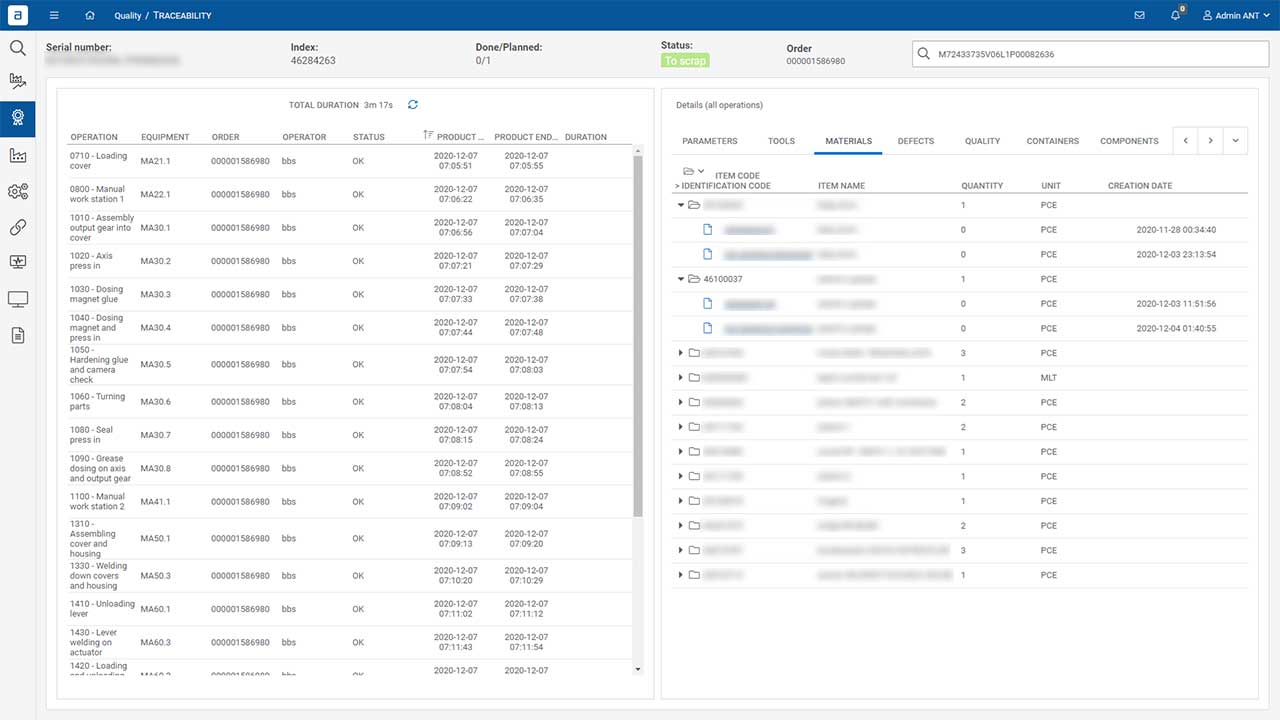

It’s no secret that every step of the pharmaceutical manufacturing process must be documented. However, managing paper documentation can be extremely time-consuming for pharmaceutical manufacturers,