ANT

PRODUCTS

OEE Performance Monitoring | MES | Smart Machine | Paperless

Out-of-the-box Software for your factory

Select

Category

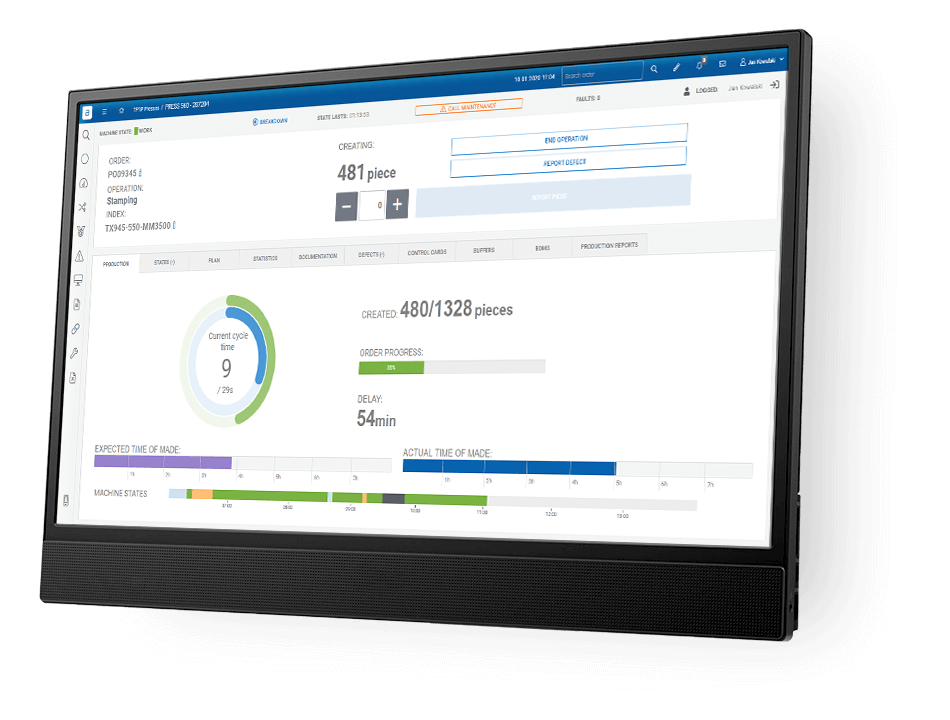

OEE PERFORMANCE MONITORING (OEE)

The system focuses on gathering data from machines, reporting production and calculating OEE factor in real-time. OEE Performance Monitoring system helps factories do the first step to monitor production, its progress and have the manufacturing process under control.

- reduction of downtimes

- faster production reporting

- shorter reaction time

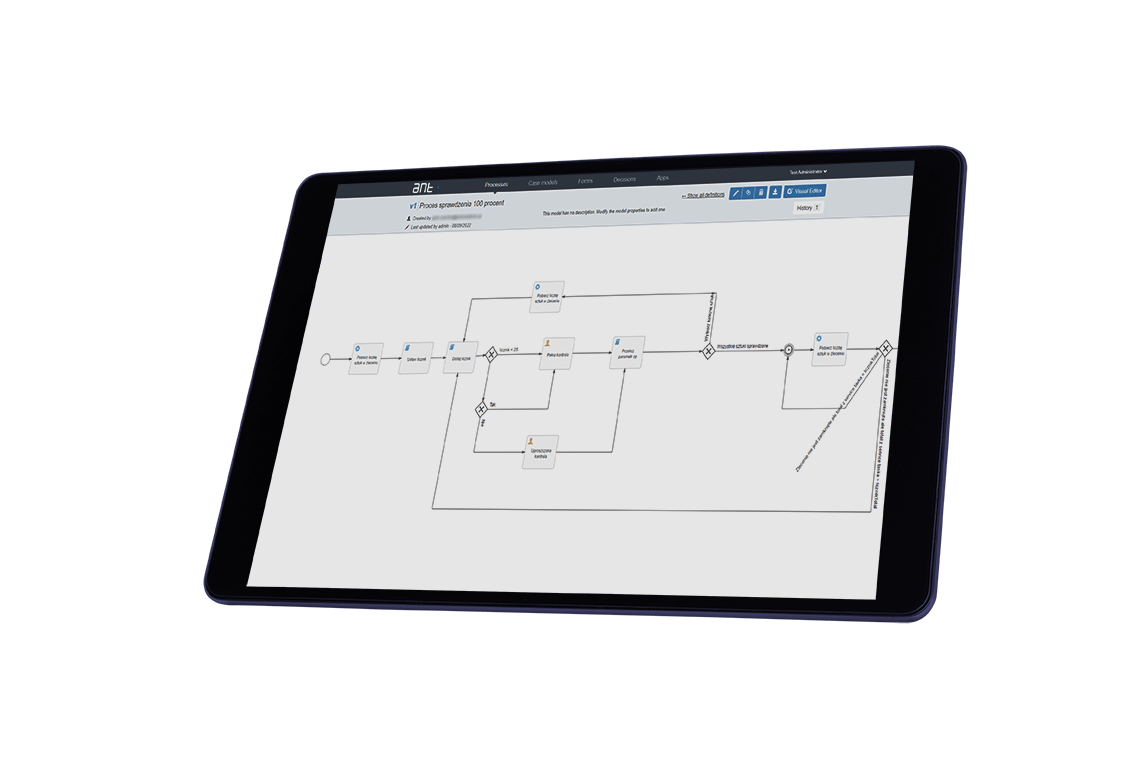

MANUFACTURING EXECUTION SYSTEM (MES)

Modern Manufacturing Execution System (MES) is a comprehensive OEE Performance Monitoring system with full Traceability, Quality Inspections and Rework management. Focus is put on process standardisation, ensuring periodical quality measurements, validation mechanisms and even more automation.

- get fewer downtimes and higher production volume

- reduce waste

- validate and control the production with ease

MANUFACTURING OPERATIONS MANAGEMENT SYSTEM (MOM)

Manufacturing Data Operations System (MOM) is an extended MES with Microstops Monitoring, Machine Control, and Paperless. Even more profound integration with automation level to monitor each stop, send recipes and programs to the PLC and create digital forms to eliminate current paper on production.

- minimize downtimes

- do faster changeovers

- improve production efficiency

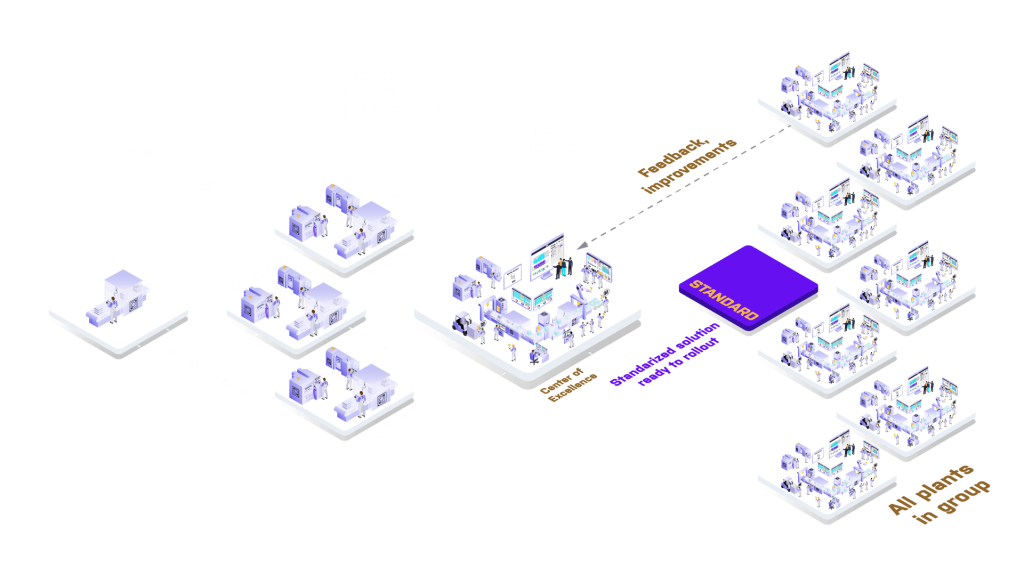

Digital Excellence Roadmap

Modular build perfect suited to your Digitalization Roadmap

1st phase

OEE Performance Monitoring

2nd phase

MES

3rd phase

Production Data Management System

SMART MACHINE (SM)

Smart Machine is a complete line control system supporting all operations and operators’ activities dedicated to automated assembly lines. The system provides automated changeovers on the fly and advanced line control of all WPCs on each station.

- increase production volume

- do faster on-the-fly changeovers

- reduce waste thanks to 100% quality control

Energy & Utilities

ENERGY MANAGEMENT SYSTEM (EMS)

The Energy Monitoring System (EMS) provides all utility consumption monitoring in real-time used in the factory: electric energy, gas, water, compressed air, heat or steam. It helps find where there are too high utility expenses, standby losses or consumption without production.

- lower utilities expenses

- reduce standby utilities losses

- leaks detection

Sign up to our newsletter

Continuous Improvement

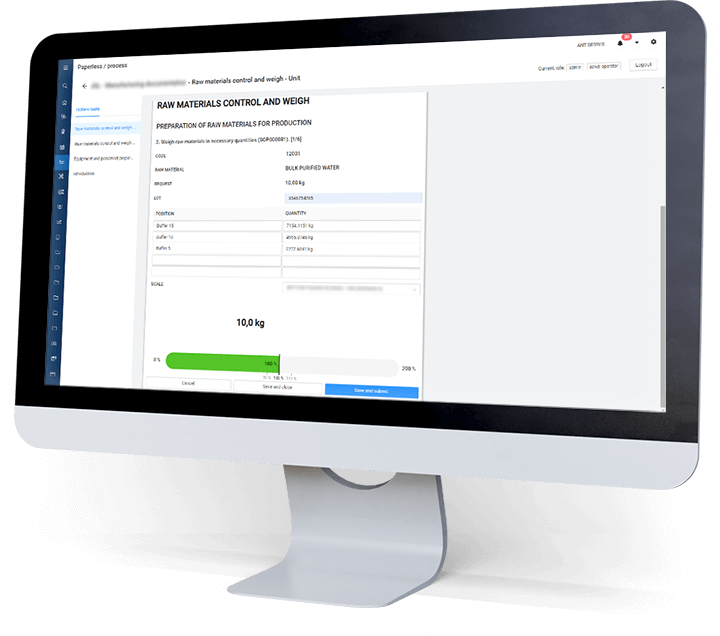

Electronic Batch Records (EBR)

The Electronic Batch Recording (EBR) technology is used to monitor the manufacturing process. It comprises tracking production data, creating reports, and keeping track of the creation of various batches.

- reduce time of batch control

- reduce batch release time

- mitigate errors and deviations

Quality, Planning, Maintenance & Warehouse Systems

Advanced Planning and Scheduling System (APS)

Continually increase productivity with the aid of a sophisticated algorithm. Real-time cycle information based on previous data can be used to automatically reschedule plans and introduce more realistic plans using a drag-and-drop interface.

- cut down on the time spent manually updating the plan progress

- Single-shift production can ensure on-time delivery while replacing two-shift production.

- keep delivery on schedule despite dynamically shifting priorities

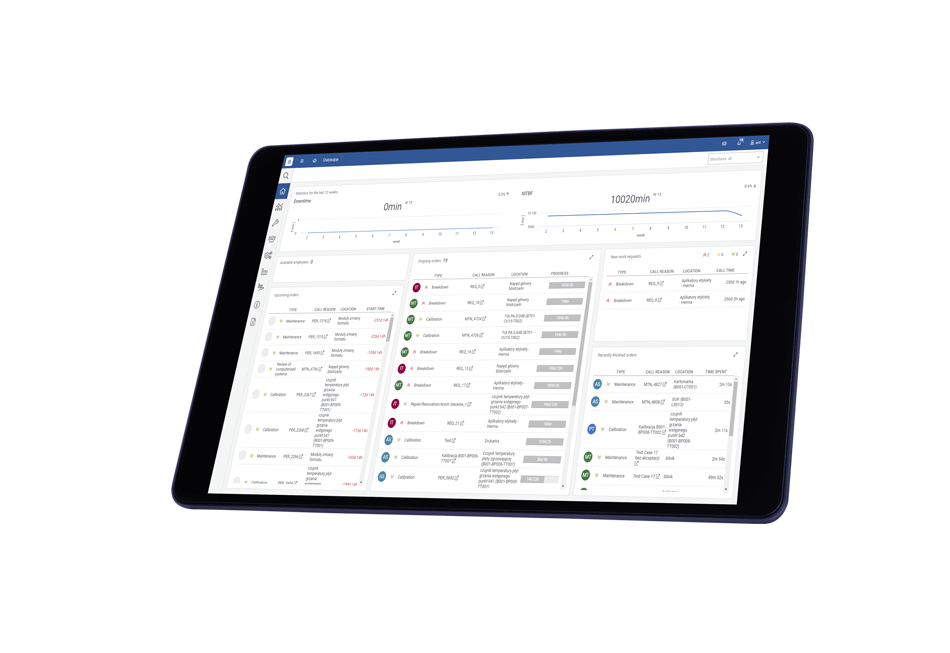

Computerized Maintenance Management System (CMMS)

With ANT’s CMMS, a new maintenance system that enables you to schedule repairs and inspections based on actual machine cycle work time, you can plan, manage, and respond.

- reduce stops and downtimes

- reduce overall repairs

- increase key maintenance indicators MTTF, MTBF

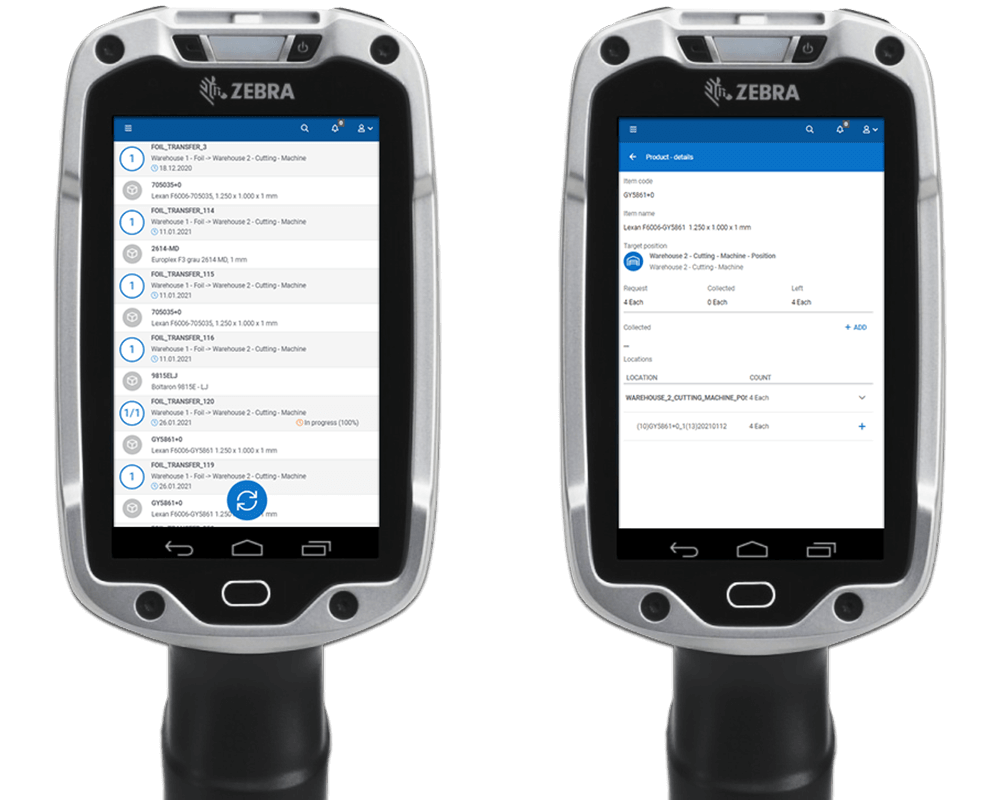

Warehouse Management System (WMS)

Users of the ANT Warehouse Management System (WMS) can manage warehouses by selecting the appropriate products and locating them using an intuitive user interface and real-time stock updates. To speed up the production process, send supplies and parts just in time.

- finding and locating supplies and products faster

- track and trace all admissions

- analyse reports

Quality Management System (QMS)

Management of incoming control plan with planning of inspections, start-up checks list to release production shift and ensure quality control. Generation of reports as products audits, 5S or TPM audits.

- less defects and scraps

- saved time

- reduced cost

Start small, scale fast