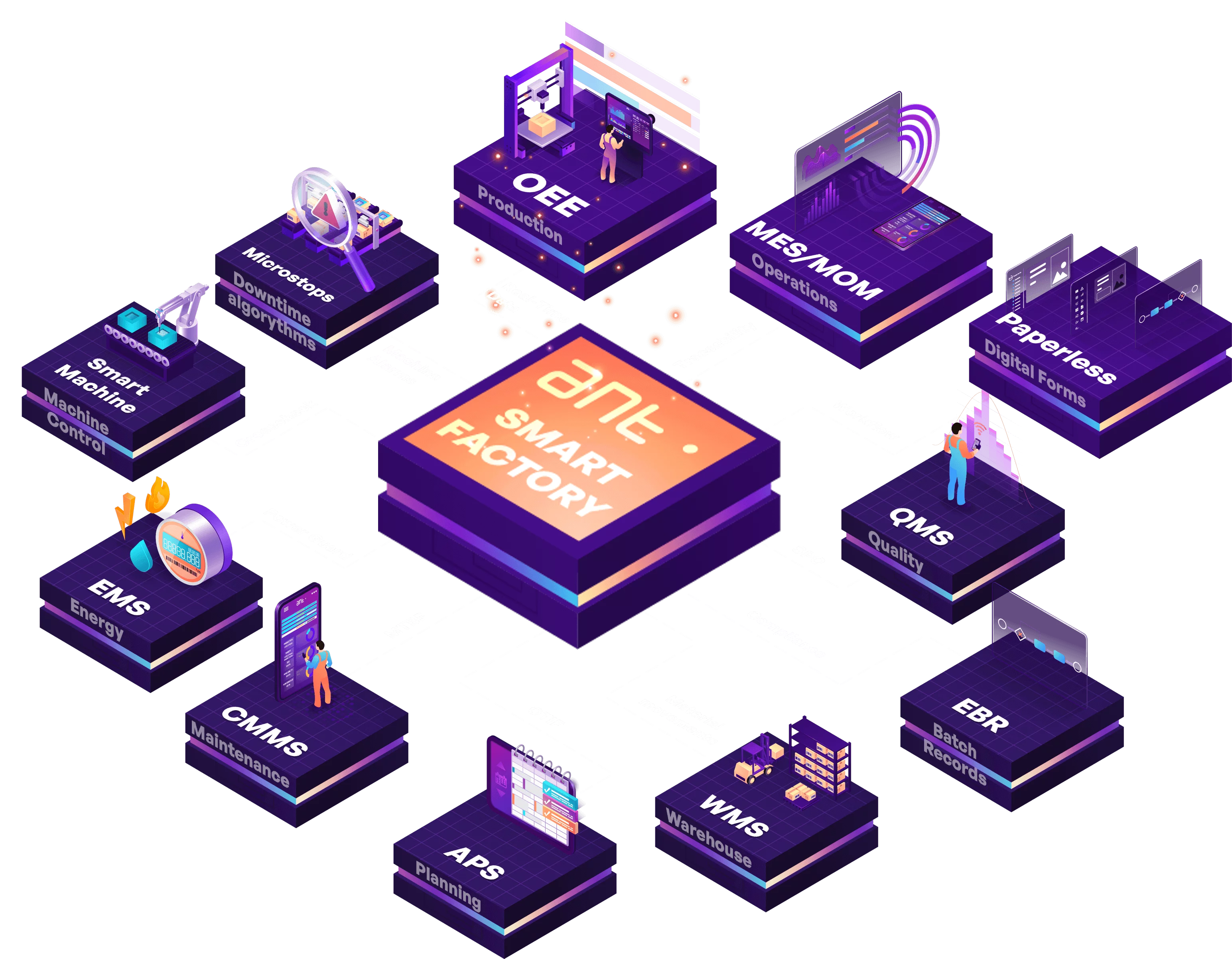

WHY ANT SOLUTIONS?

Leading Machine

Connectivity Solutions

Independent Software

Provider

ANT Solutions is a specialised software development company with over 18 years of expertise in delivering customised IT solutions to factories. Our mission is to enhance the productivity and efficiency of manufacturing processes through innovative technology. With a rich history of serving the industry, we have established ourselves as leaders in developing solutions that meet the unique needs of each factory.

ANT Solutions is a specialised software development company with over 18 years of expertise in delivering customised IT solutions to factories. Our mission is to enhance the productivity and efficiency of manufacturing processes through innovative technology. With a rich history of serving the industry, we have established ourselves as leaders in developing solutions that meet the unique needs of each factory.

In 2023, ANT Solutions embarked on a new chapter by joining forces with Dürr Group and ITAC Software, expanding our capabilities and reach in the manufacturing technology sphere. This partnership signifies our commitment to providing state-of-the-art solutions and marks a milestone in our journey towards revolutionising manufacturing through digital transformation.

Manufacturing in the region for the region, next to our customers is a pillar of our operations strategy.

We invested massively in our factories over the last years to increase capacity; completing these investments with the best digitalization solution of all manufacturing systems is a key part of our program toward more efficiency and agility. In a great collaboration with ANT, we are rolling out our plans.

Fabrice Revert, COO

LinkedIn

End-To-End project with complete range of services for the implementation of project:

- on-site analysis

- machines connectivity

- ERP integration

- hardware delivery

- system implementation

- trainings

- system handover & SLA

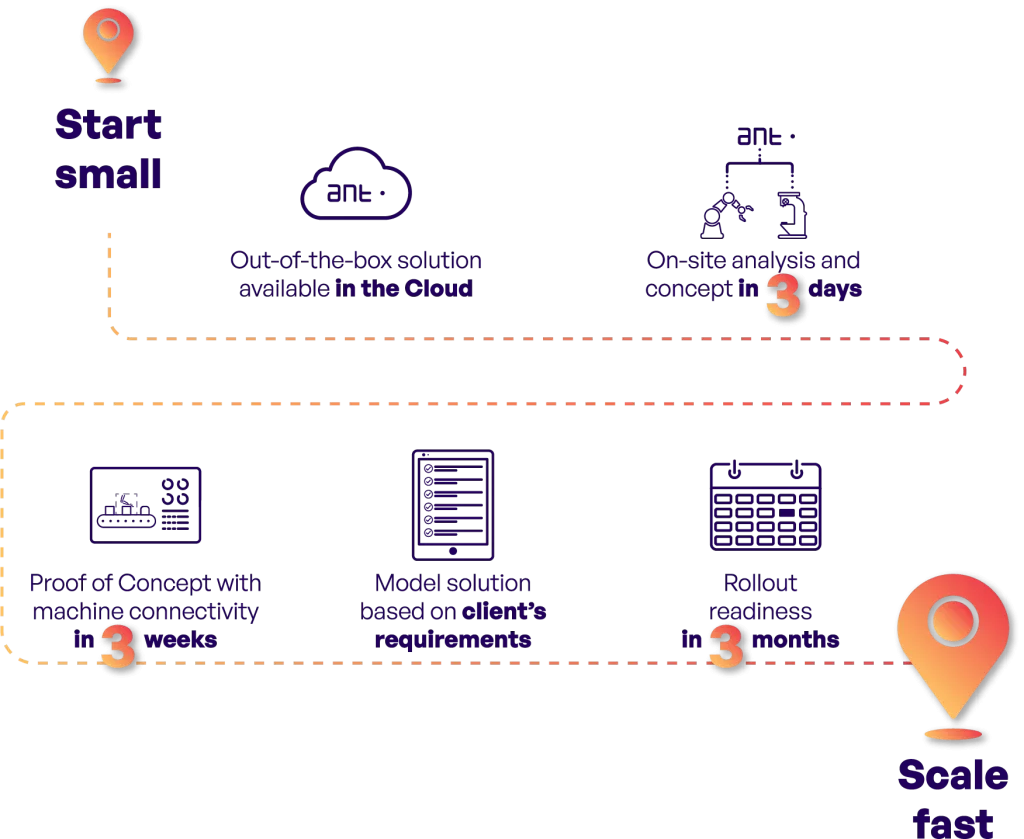

Quick Implementation

We do it on time!

• Guarantee project duration in contract

• Pilot project in 3 weeks

• Full project in 3 months

• Detailed timeline with its monitoring

• Work in SCRUM framework with 2 weeks product increment

Proven Solutions

Perfect for Industry 4.0

• Ready product – implemented and verified by hundreds of Clients

• Working and tested in different industries

• 600+ implementations completed in small, medium and worldwide corporations

• Worldwide presence (35 countries)

• Ready to launch in a couple of weeks

Machine connectivity

We will connect all your machines!

- Focus on machine data collection

- Communication with new and old machines

- Counter and process parameters read from PLC, HMI, electrical cabinets

- Dedicated solutions: sensors, acquisition boxes, cameras

- Modern IoT architecture with data offline buffering

Modifications

You need changes and that’s OK!

• Any modification is possible

• System is flexible to be adjusted to production processes and its uniqueness

• We work in our own system platform (AOS)

• ANT owns the source code

• No 3rd party applications

Dedicated Team

We know you, you know us!

• Team of 10 engineers dedicated to the project

• Direct contact

• The same team for roll-outs

• Professional project management

• Best software implementation practices

Modern technologies

Don’t stay behind…

• Cloud support (Azure, AWS, MQTT)

• Clean and user-friendly dashboards – thanks to UI and UX design

• Automated mechanisms for deployment of the new version (DevOps)

• Modern programming languages (JavaScript (JS), TypeScript (TS), Node.js, React)

• Can be run on mobile devices

Standarized implementation method

Hardware installation

- Automation parts on-site installation (converters, sensors, I/O modules, cameras)

- PCs, TVs, printers, electrical & network cabinets installation on-site at production

- Wiring infrastructure (power, ethernet, sensors communication)

Benefits:

- Outsourcing hardware installation (not using factory staff)

- Low risk: one partner responsibility

- Worldwide experience with dedicated team

System implementation

- Ready to use product

- Proven solution used by top manufacturing factories

- Professional project management (ITIL, SCRUM, DevOps)

Benefits:

- Modern, stable and tested solution ready to use from day 1

- Perfect communication during the project (on-line tools)

- Minimized factory’s staff engagement

Customizations

- Each factory is different, each process is specific and unique

- Open ANT platform enables any modifications

- 80% out-of-box solution, 20% is customization during the project

Benefits:

- The solution can be customized for the factory’s need

- Implementation is done by software manufacturer with access to source code

- You have an impact on ANT’s platform development

System design

- On-site kick-off analysis & conceptual design

- Automation audit and machine connectivity plan

- Concept creation with as-is and to-be factory processes

Benefits:

- Low-risk thanks to the detailed analysis

- Fix project budget

- Detailed project timeline with clear actions-to-do

IIoT machines connectivity

- Connection with new and old lines & machines

- Standard machine communication protocols

- Various machine connection methods (PLC, OPC, sensors, I/O modules, cameras)

Benefits:

- All machines data acquisition in one system

- Low risk: one partner responsibility

- Automated and precise real-time OEE: Availability measurement

ERP Integration

- Download production and technology from your ERP system

- Upload production reports and statuses to your ERP system

- Deep integration ANT MES with external systems like WMS, APS, DMS, PLM

Benefits:

- Production reporting time reduction

- No need for double production reporting in both ERP and MES

- Automated data synchronization to keep data integrity and management only in one, main system

Training & System handover

- Full training plan & documentation as a part of the project

- Train the trainer (on-site and offline sessions)

- UAT’s checklist during system handover

Benefits:

- All staff is trained and ready to use the system efficiently

- Full knowledge about the system stays in the factory

- First-line support presence in the factory: System Owner

SLA Support 24/7

- Promised reaction and resolution time

- On-line access to Service Desk 24/7

- Worldwide remote assistance

Benefits:

- Low risk that the failure impacts on production continuity

- Fast reaction and resolution of issues

- Support activities monitoring online and in real-time

Cloud approach

- Modern architecture: Platform as a Service (PaaS)

- All data in the cloud

- Data buffering on factory’s Edge device in case of the Internet lost

Benefits:

- ANT is responsible for all Platform: High Availability, scalability, upgrades on the fly

- No IT maintenance costs

- Reduce local IT responsibilities

Biscuits Factory

- Find out what problems biccuits factory was facing before implementation OEE factory software.

- What was ANT Solutions approach to deal with uncovered factory issues.

- How ANT Solutions implemented the key software components including hardware and cabling.

- The final outcome resulted in key KPIs increase.

Assembly Factory

- Company implemented an MES system to improve manufacturing efficiency.

- The MES system enabled real-time production monitoring, quality inspections, and defect handling.

- The MES system helped factory to increase efficiency, reduce defective products, and improve data accuracy.

- Find out how ANT Solutions MES implementation, helped manufacturer increasing it’s KPIs.

Tobacco Plant

- This case study describes the customer case study of a successful micro stops implementation in a tobacco factory.

- The factory system enabled automated data gathering and key algorithmics.

- The system was implemented to address the challenges of high-speed production, micro stops, SKU and changeover times, and a diverse machine park.

- Find out how ANT Solutions enabled communication with over 100 machine types, algorithmics creation, and roll-out to 30 factories.