How to monitor utility expenses in factory production?

The rising utility costs – especially for electricity obtained in the traditional manner – raise the importance of efficiency in the use of these resources.

ANT Energy Management System (EMS) is an industrial software to monitor utilities consumption online (like energy, gas, fluids and more). Power management system presents consumption per areas (departments, production lines) and per production (order, item) which helps to calculate real manufacturing cost. Solution forecasts energy usage and creates alarms if the site is reaching the contractual capacity. With the system you can detect failures, leaks or anomalies and have information how much utilities were used during non-production time. ANT EMS is ISO 50001 compliant solution for monitoring energy in your factory.

We provide dedicated sensors to monitor all utilities

We enable system to read basic and advanced parameters

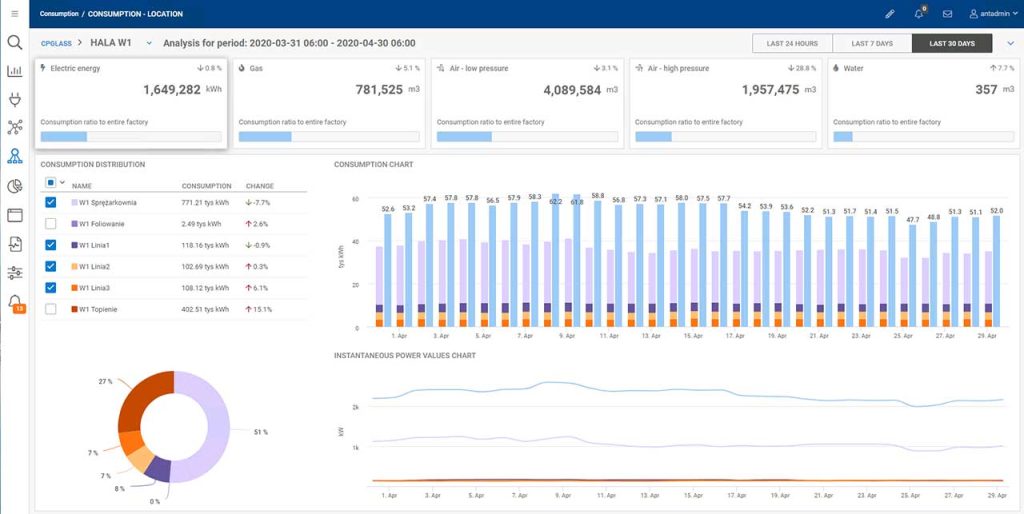

Compare energy usage with production results

Main axiom of Lean Management is: “You cannot manage what you cannot measure”. ANT energy management software aims at complete control over the use and cost of utilities in the factory. Counters, alarms and controlling dashboards give user a possibility to manage the utilities as well as possible in all parts of the factory – from production floor to offices. Correlation with production data allows for full analysis and transparency of the actual production costs. Active industrial monitoring supports detection of leaks and waste of utilities that can be easily missed and just as easily fixed.

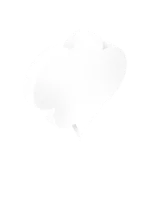

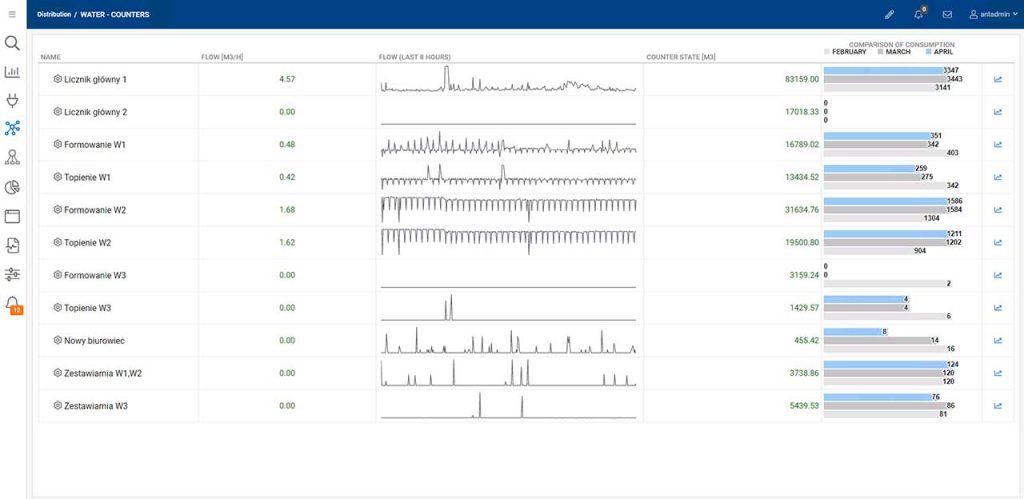

Analysis of all utilities in current location with detailed information on planned and actual usage as well as displaying trends and forecasts

Data on utility consumption can be correlated with production data, showing an accurate picture of total production and non-production costs

Display utilities consumption in different areas with additional correlation with production data, updated in real time

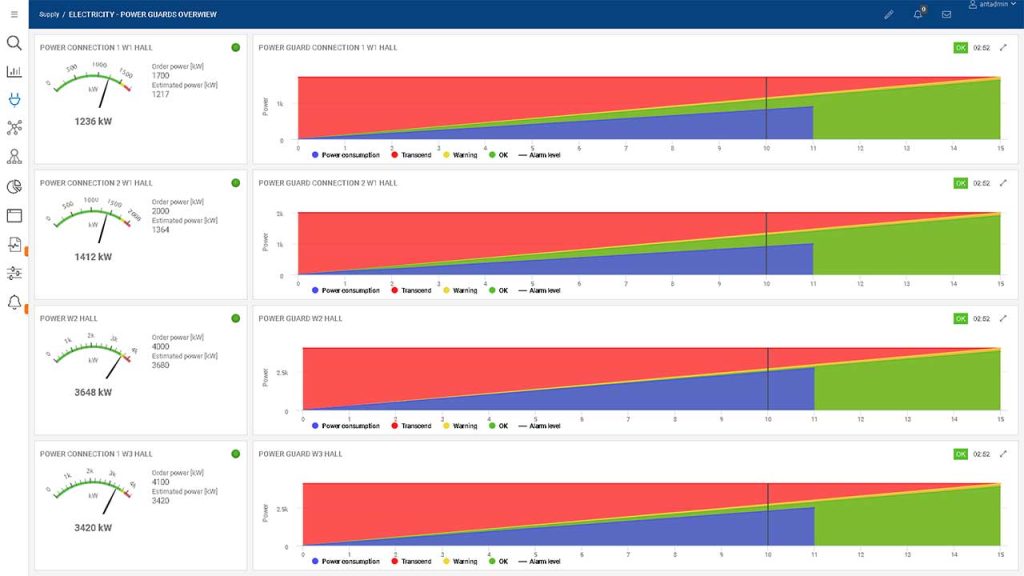

Power Guard is a tool used to control the amount of electrical power used vs ordered in order to avoid costly penalties for breaching the limits. Through active tracking the system will issue warnings on the incoming breach with proper advance

Display plant structure with counter states and power charts, filled with automatically gathered data

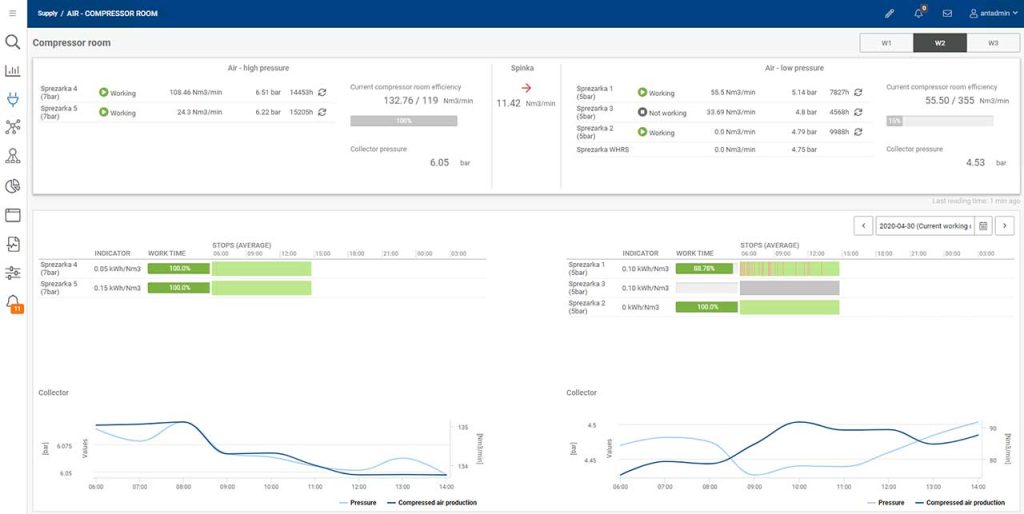

Display of current status of compressed air, it’s details, consumption and efficiency

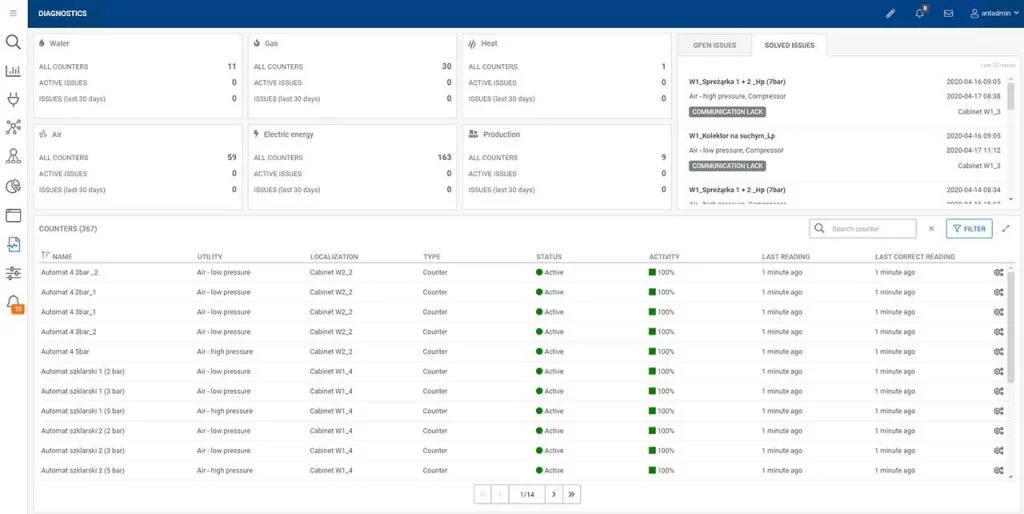

Administrator panel giving control over state of communication with counters, their general condition and active issues

The first level of system validation:

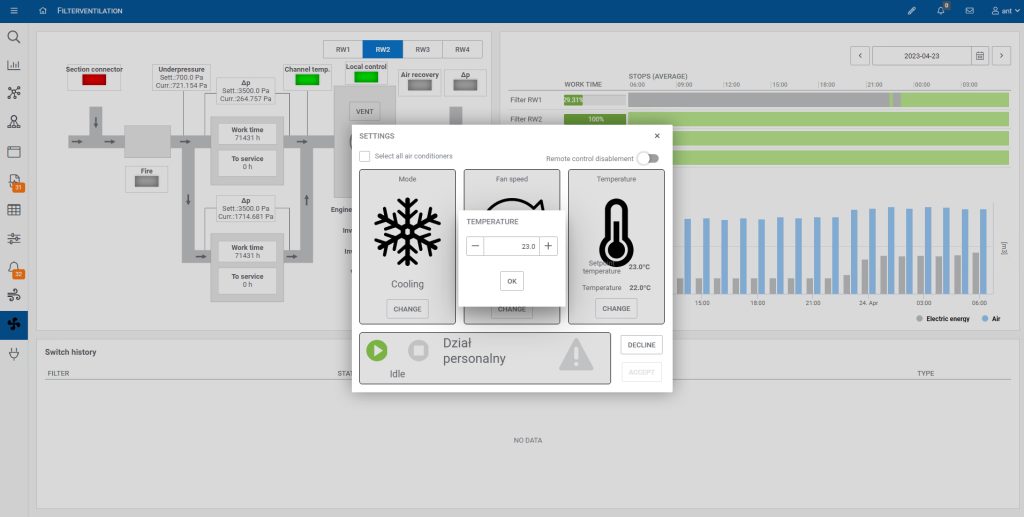

Efficient HVAC Control: The Building Management System (BMS) module provides precise control over HVAC systems, optimizing comfort while minimizing energy waste.

Intelligent Lighting: The BMS module enables smart lighting controls based on occupancy, calendar and daylight, reducing energy usage in factories.

Real-time Monitoring: The BMS module continuously monitors heating, ventilation and air conditioning equipment to optimise performance in the factories.

Seamless Integration: The BMS module seamlessly integrates with other systems, through OPC, RS232, converters and standard protocols enabling reading and control.

Act SMART and connect entire facility within a single system rollout.

The rising utility costs – especially for electricity obtained in the traditional manner – raise the importance of efficiency in the use of these resources.

The FMCG industry faces new challenges every year. Production in line with government requirements and the need to meet the increasingly high expectations of end

Energy management systems (EMS) enable companies to monitor and measure energy consumption. An EMS is an automated system that monitors, measures and analyzes the performance of an organization’s energy-consuming equipment and systems. They are designed to save an organization money by reducing energy consumption and improving energy efficiency. Each company can develop its own EMS according to its needs and capabilities. These systems usually regularly collect data from the production line including gas, liquid, steam and other utility consumption data.

There are many ways to measure energy consumption, but the most common way is to install sensors in the production process or use appropriate software. This allows you to monitor the electricity, gas or fluids that are used during the production process. The data collected from these sensors can be used to calculate how much energy has been consumed over a certain period of time. This information can then be used to make adjustments and optimize processes that require high energy levels.

High production efficiency rates depend on optimal use of available resources. Energy required for the process to work properly is one of them. How does energy consumption affect business performance? Misuse of energy resources increases production costs and thus reduces company’s income. Investigating the power consumption of a plant requires technologically advanced tools such as energy monitoring system EMS. How does it work, and what should you consider when choosing a power consumption monitoring system for your plant?

Optimal energy consumption results not only from the need to reduce production costs. The globally applicable ISO 50001 standard is the international standard for efficient energy management in the economy, including manufacturing companies.

An advanced electrical power monitoring system enables production plants to operate in compliance with the rules. Energy Monitoring hardware is integrated with the system being the source of energy and the devices consuming it for operation. A power monitoring unit sends the collected data to the system. EMS enables ongoing electricity monitoring in the plant and indicates possible opportunities and risks.

Where do companies get information about their energy consumption? One of the primary sources of information is energy bills. This solution is extremely poor, as it does not reveal production bottlenecks. Industrial power monitoring system is an advanced technology that collects data on the energy consumption of equipment used in a plant. Remote power monitoring provides permanent insight into energy efficiency and the ability to estimate costs.

Moreover, the energy consumption monitoring system enables comparative analysis of data, so that you can quickly determine whether all machines are consuming the required amount of energy. The energy monitoring system isolates the modes of operation of the equipment, individually evaluates the level of consumption and indicates optimisation opportunities. An energy consumption report allows you to calculate the amount of power needed to produce the final product.

Energy Monitoring hardware also shows excessive power consumption. It may turn out, for example, that a minor appliance malfunction will result in excessive consumption. You will not find out about this from the bill sent by your electricity supplier but through a system that offers electricity monitoring.

An energy monitoring system also allows for the implementation of additional software, such as a contracted capacity guard. What is this guard? Each energy supplier agrees the contracted power, that is the maximum electricity consumption, with the customer. With EMS, it is possible to monitor power consumption in real time and predict possible overloads. Advanced system options suggest which devices should be switched off to prevent exceeding the contracted capacity. In this case, there is also an option to automatically set devices that do not affect the process.

EMS can be defined by two words: optimisation and safety. An energy monitoring system is an opportunity for a company to reduce power consumption and prevent excessive costs.

The industrial power monitoring system extracts data from units. The energy consumption report allows constant monitoring of the data. Two identical devices should consume the same amount of energy. If a report in EMS shows that one machine is consuming 5-7% more energy, this may indicate a latent equipment failure. Electricity monitoring enables a rapid response eliminating the need for costly repairs detected too late.

Energy monitoring products also help optimise energy efficiency. A comparative analysis shows which solutions generate savings for the company. Automation of activities, such as switching machines on or off or installing motion sensors to activate a light source in a room, is one of the elements.

A dedicated electrical power monitoring system is the best solution. For any business, there is a lot to be gained by installing energy monitoring equipment at their facilities.

Digital energy monitoring products are becoming increasingly common. What do you need to know before equipping your plant with a power consumption monitoring system?

It should be noted that depending on the size of the company and the scope of operations, each company needs a different energy monitoring solution (EMS). EMS for larger companies will require more money due to the numerous functionalities and connections.

Companies that use an energy monitoring device to optimise their production costs fully agree on this – it pays off!

Download Return of Investment (ROI) Document in Molding Injection Machine Industry