Key Benefits

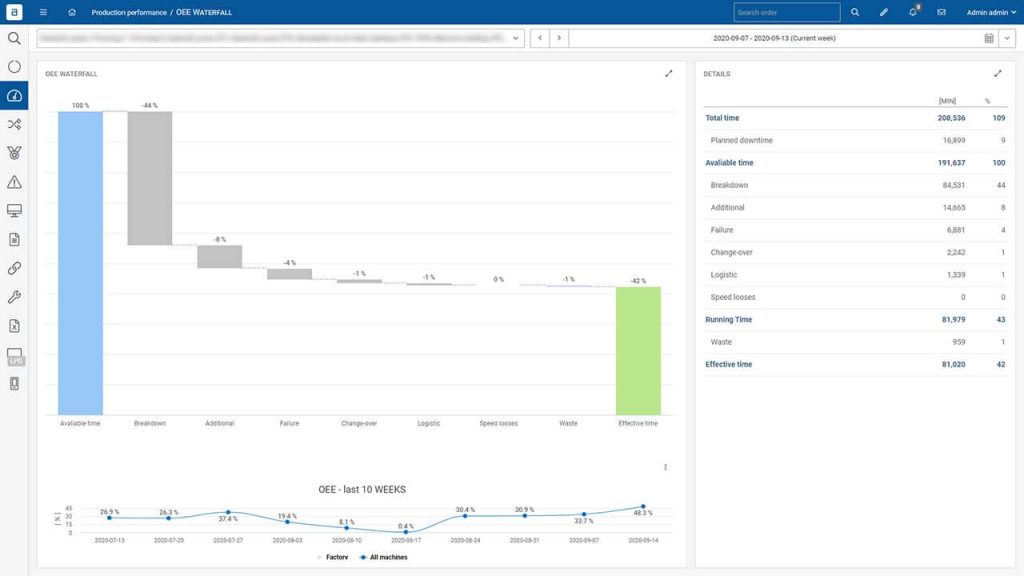

OEE

increase

✔️ shorter downtimes

✔️ faster production launch

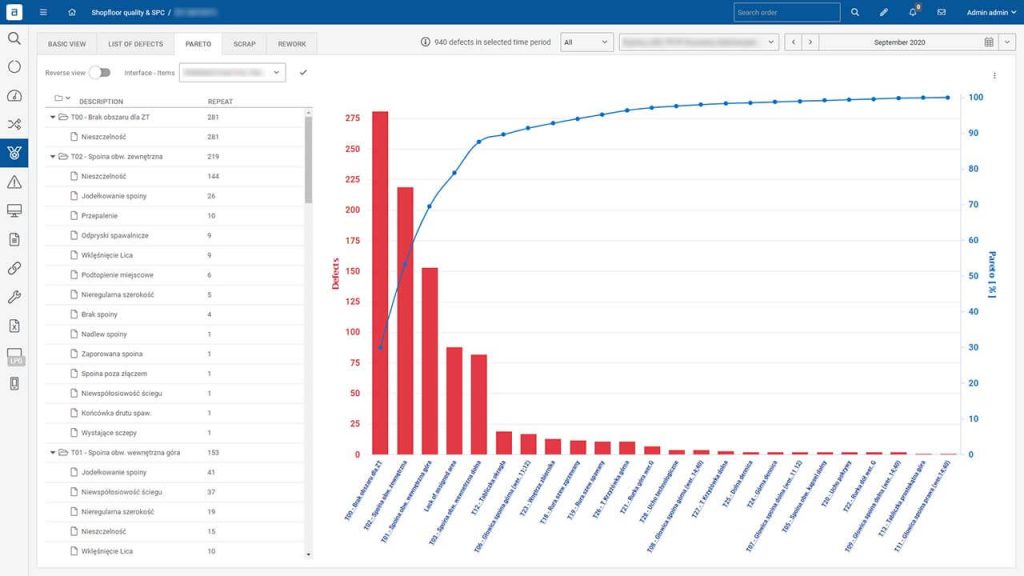

✔️ pareto defects analysis

Faster and reliable

data-driven decisions

✔️ signals taken from machines

✔️ showing real production progress

✔️ automated notifications

Elimination of double and manual reporting

✔️ automated production reports

✔️ any ERP integration

✔️ machine states from PLCs

One System For Production

OEE calculation software collects data automatically, based on the machine’s signals. Start monitoring production, its progress, efficiency and make decisions based on actual data.

What is considered a good OEE?

The answer to what is considered good OEE may vary from industry to industry and the product that is manufactured. For example, in the food and beverage industry, anything over 90% may be considered good while in an assembly line manufacturing company, 60% may be considered a strong OEE.

OEE indicator may be hugely dependent on production characteristics. Although 90% may seem like a high number in FMCG, an improvement of even 2% may play a huge role in production total efficiency, where as in discrete manufacturing it will just minor progress.

On the other hand, the implementation of OEE software may cause the OEE factor to drop significantly due to many causes which you can read more about in this article: Why does OEE drop after MES implementation?

OEE Tracking System

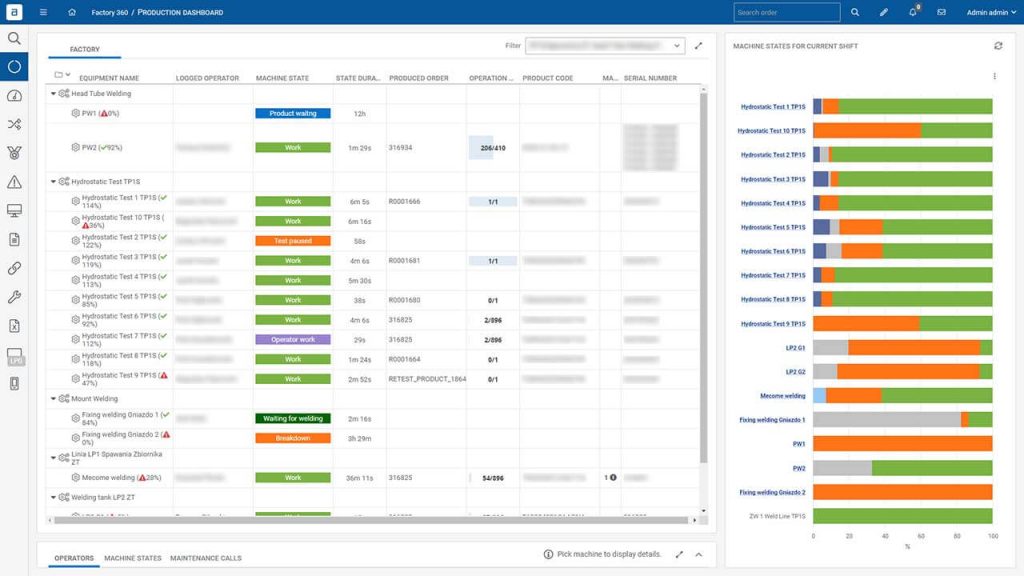

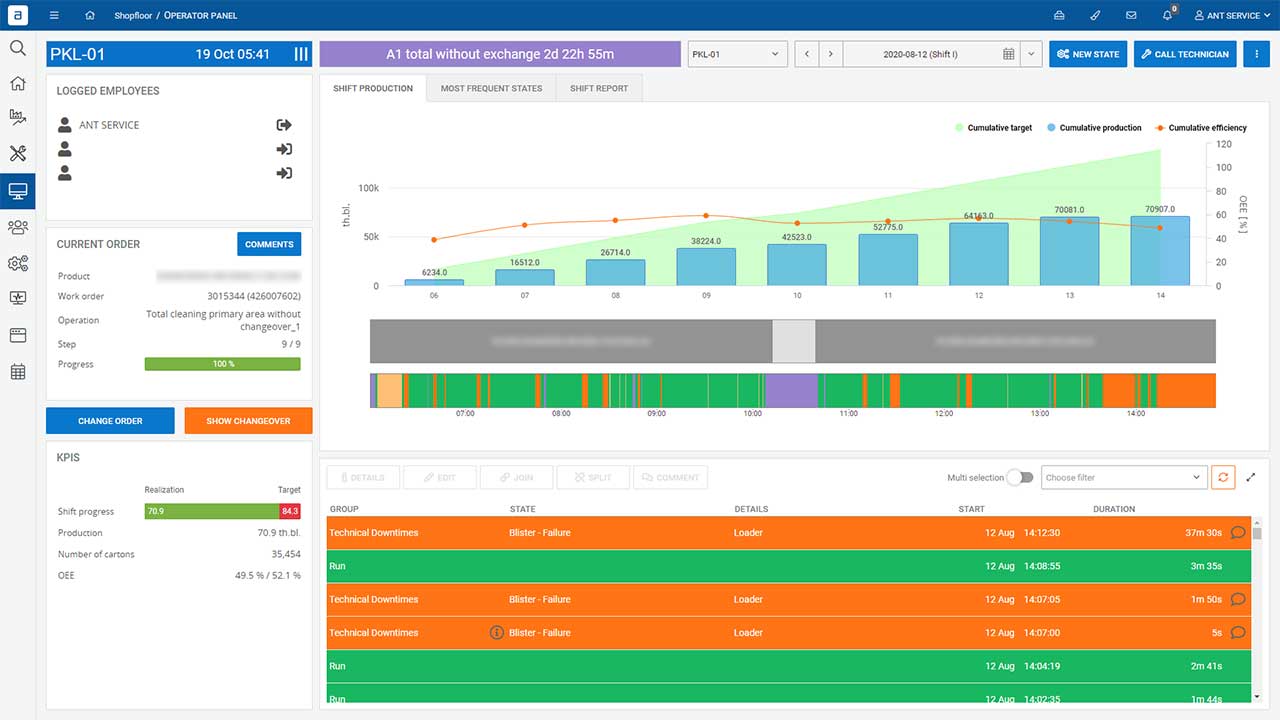

- The system focuses on gathering data from machines, reporting production and calculating OEE factor in real-time.

- OEE Performance Monitoring system helps factories do the first step to monitor production, its progress and have the manufacturing process under control.

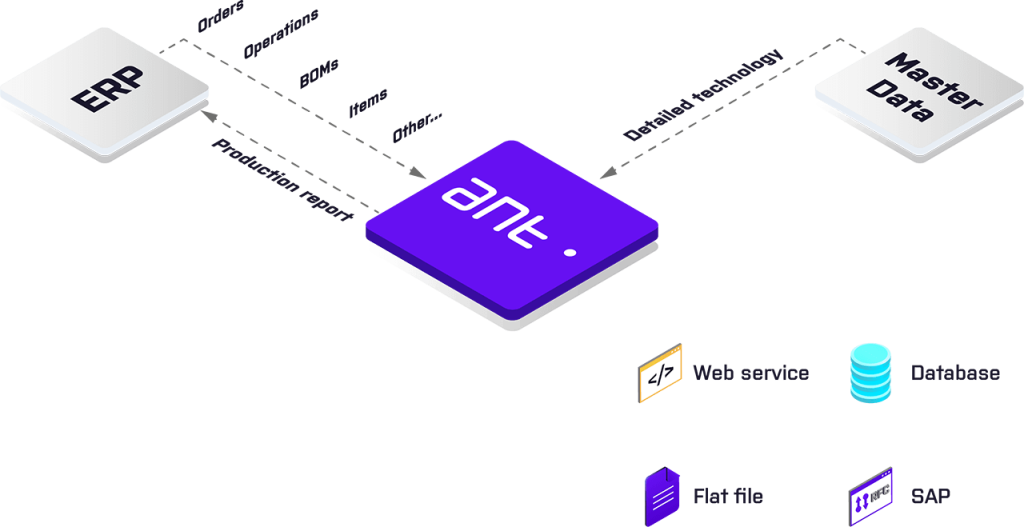

- The interface with the ERP system helps to eliminate double production reporting and exchange production data.

- Built-in dashboards & reports help to analyse defects, production, types of stoppages and failures.

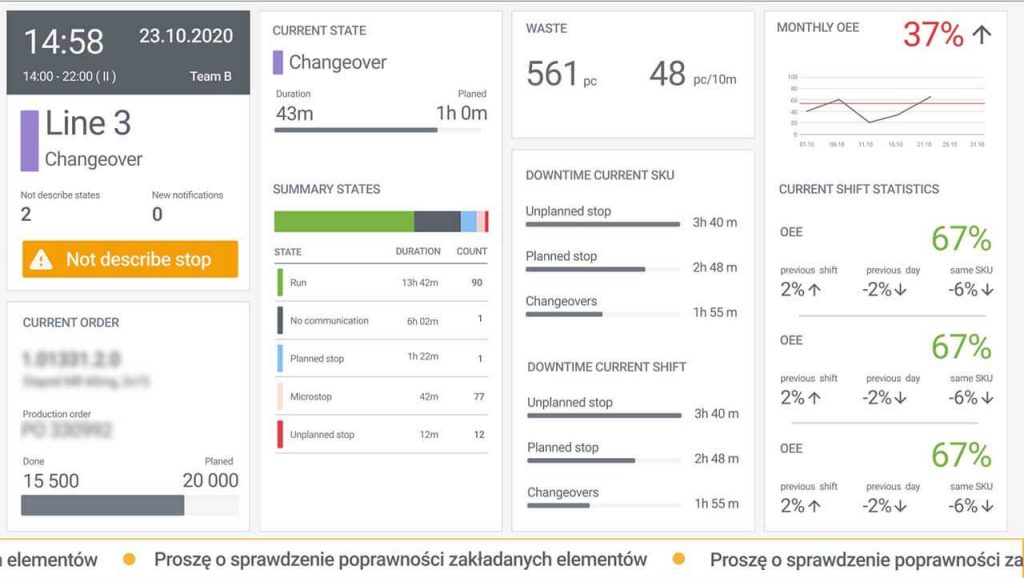

- To improve transparency, large screens on the shopfloor present OEE and production data in real-time.

- Email or SMS notifications are sent automatically based on signals from machines and operator actions.

OEE Performance Monitoring Functionalities

Machine Connectivity

We connect them all – old & new

Machine Connectivity is responsible for communication with the machine’s PLC and devices. It provides acquisition, processing and administration of data collected from the automation level. With different acquisition methods, data like machine states, quantity or process parameters are read.

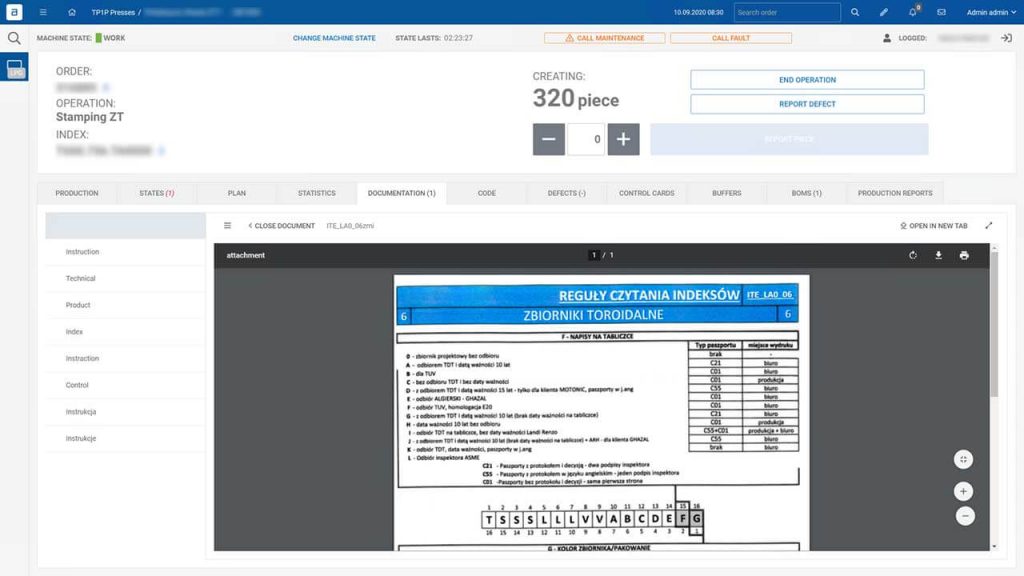

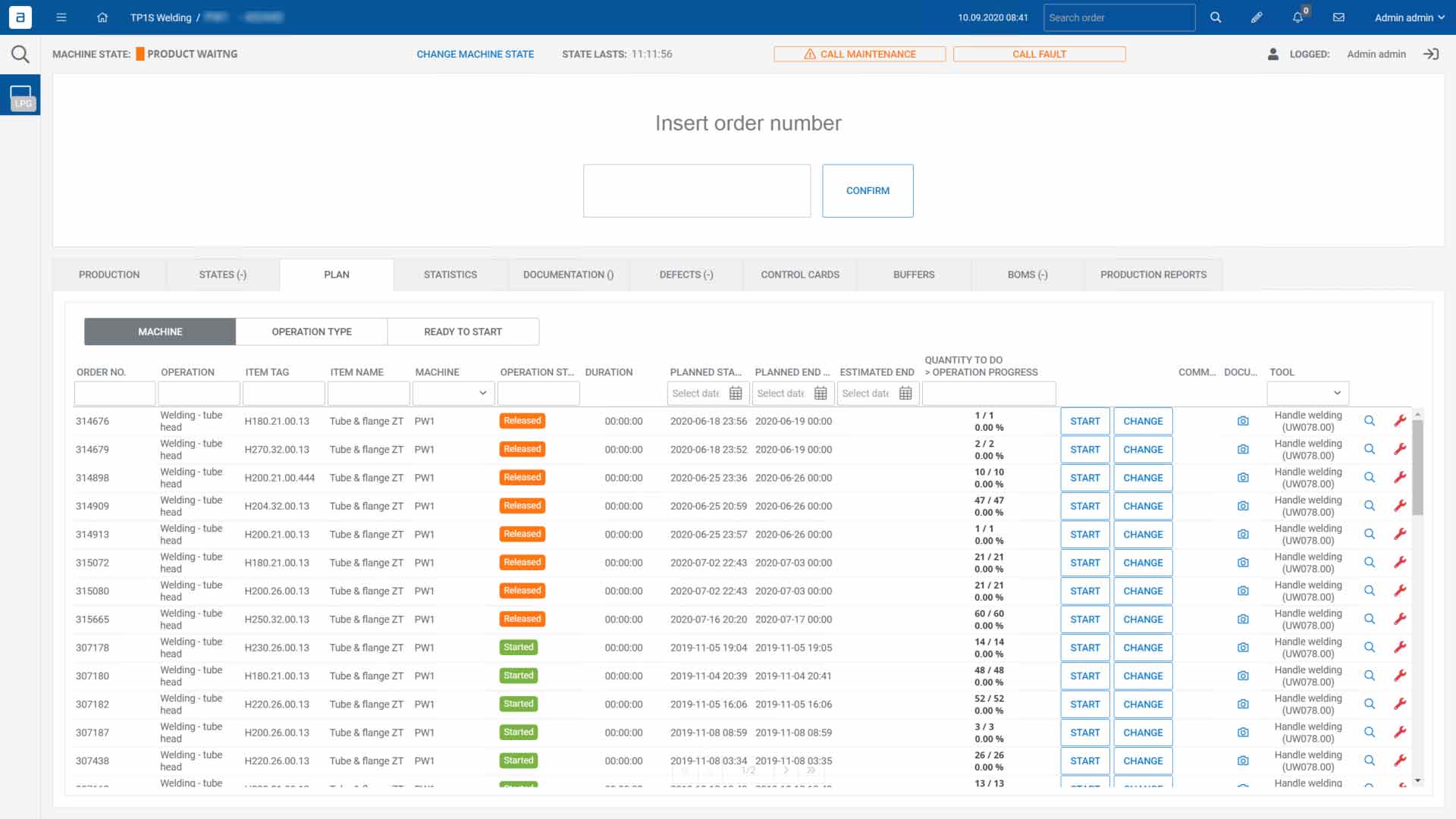

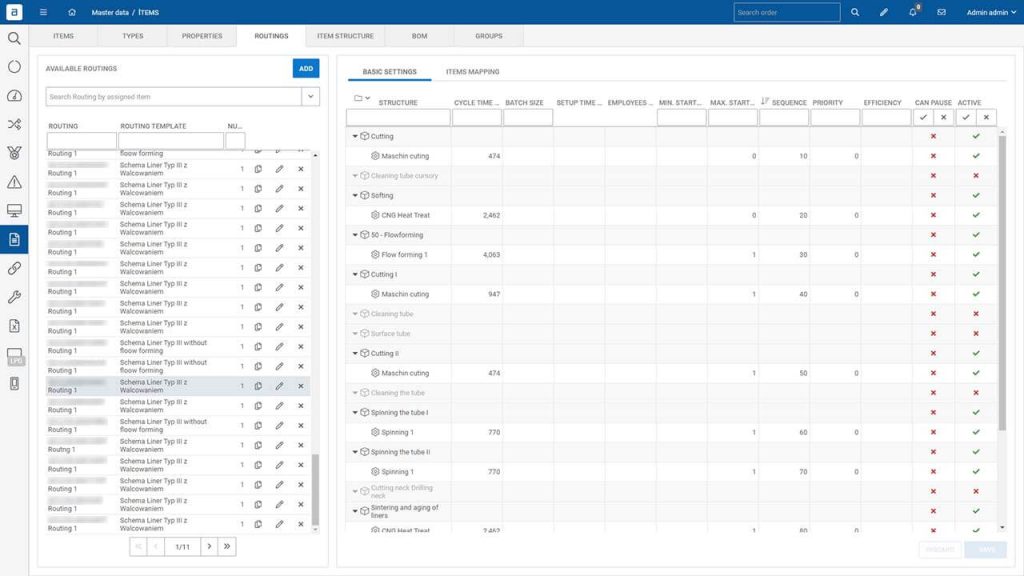

Production execution

Report production and monitor it

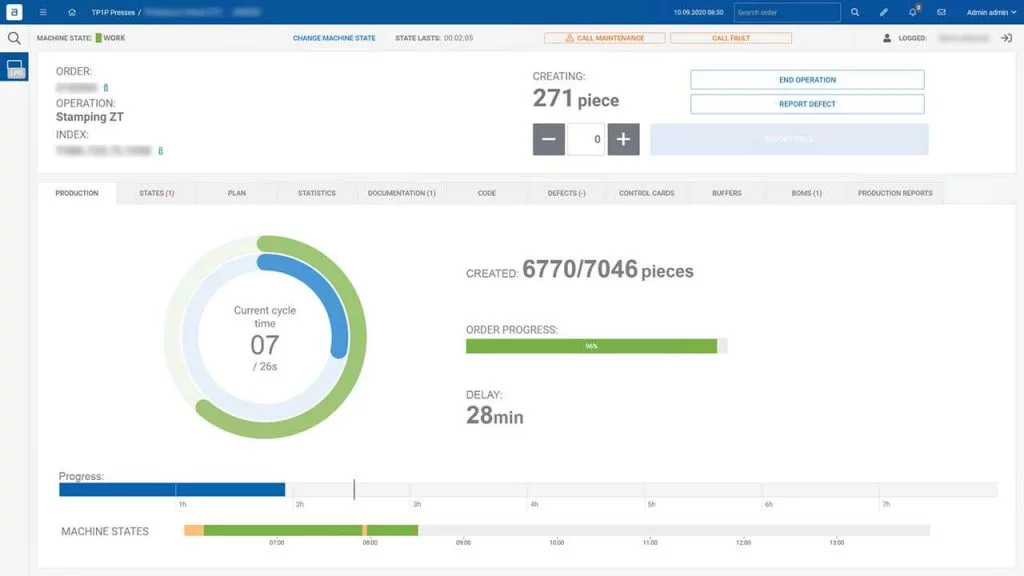

Production Execution let operators to execute orders and operations according to plan and technology. It validates and supports different type of production processes during which operator can report production and machine states. System displays current production, its status and progress.

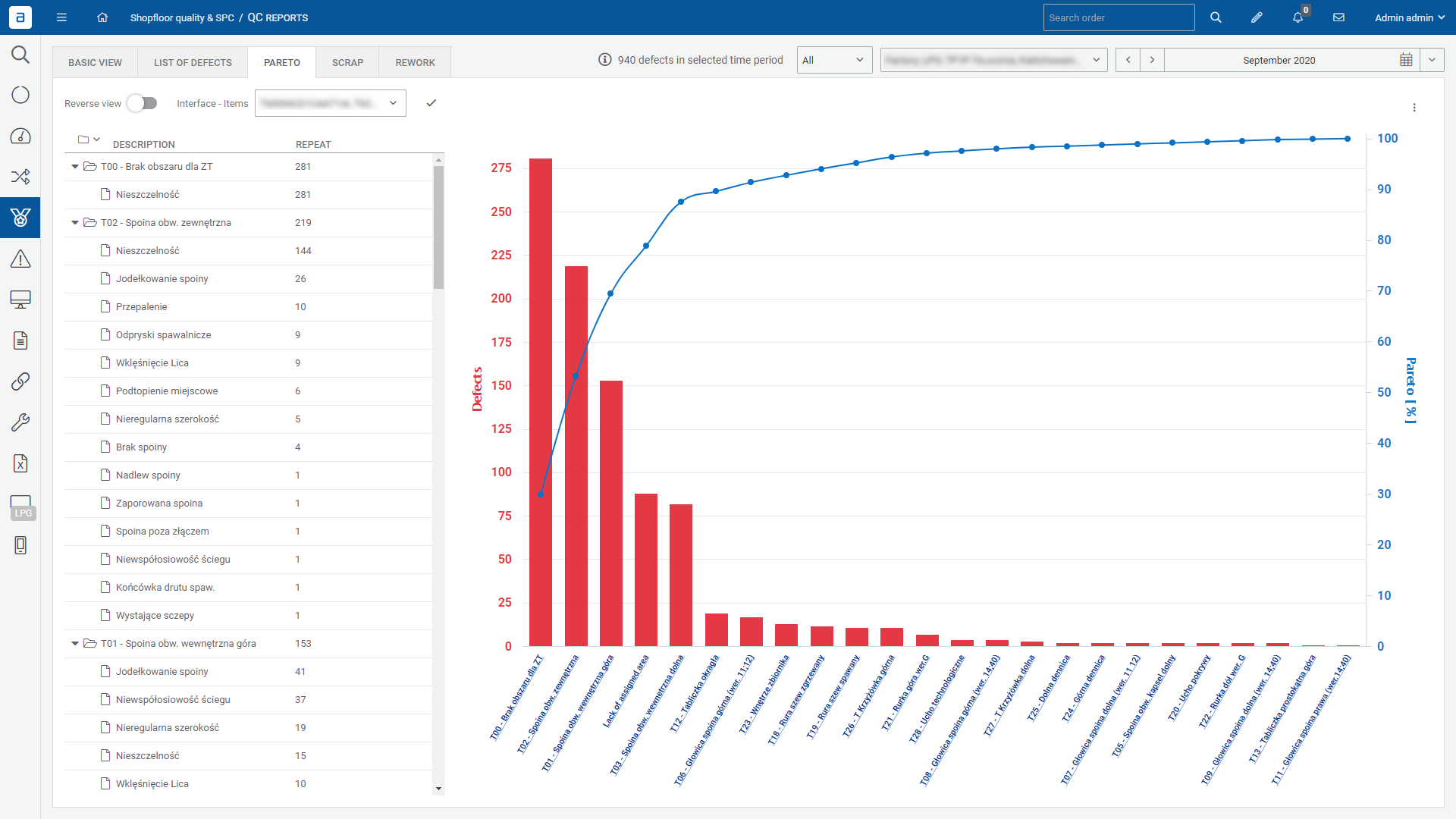

Defect handling

Report defects with details

Defect Handling supports defect and scrap management. Operators can report defects and its type. System displays dedicated reports with defects reasons and quantity.

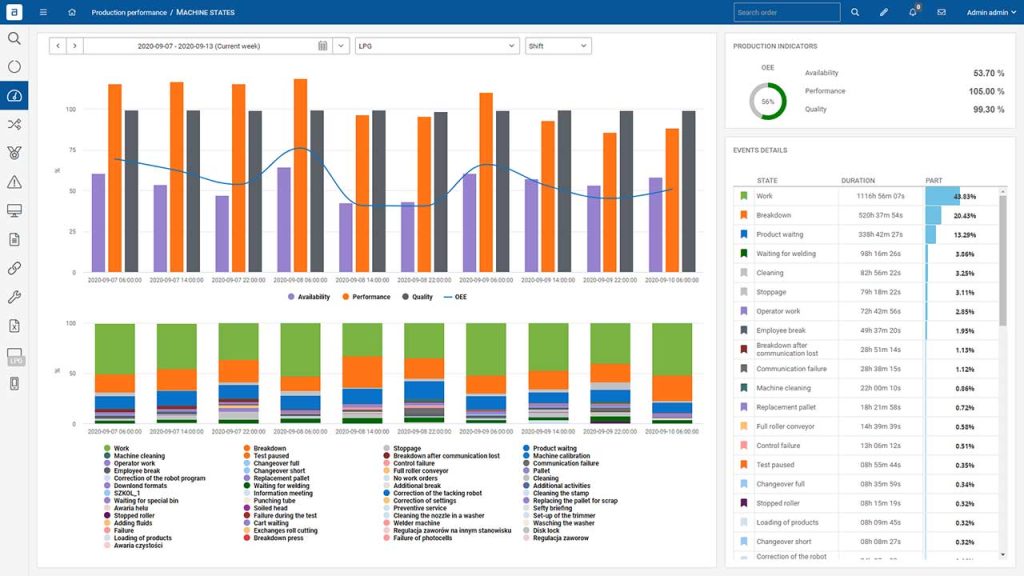

OEE Analysis

Find out where to focus

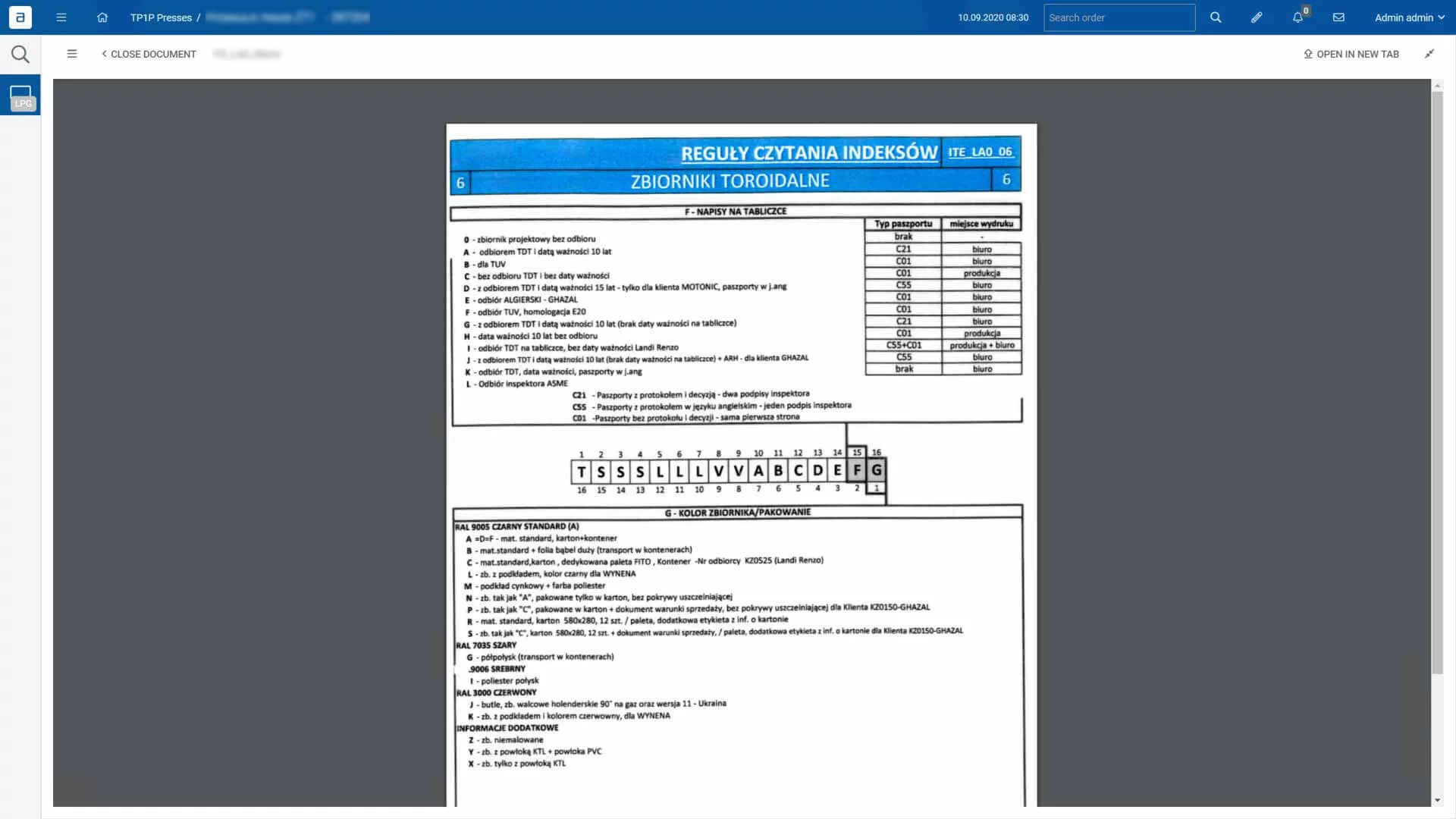

Digital Documentation

No more paper

Digital Documentation let users display documentation online at the operator panel. Categorized PDFs, images and movies are being displayed for ongoing production.

Online Visualization

See it live, see it everywhere – be transparent

Sign up to our newsletter

Dashboard & Reports

From the top to bottom analysis

Dashboards & Reports is a complex analytic platform with ready reports. More than a dozen reports analyzing production, quality, trends and targets. Reports can be viewed from the perspective of plant, machine and in different time ranges.

Master Data

Detailed modelling production processes

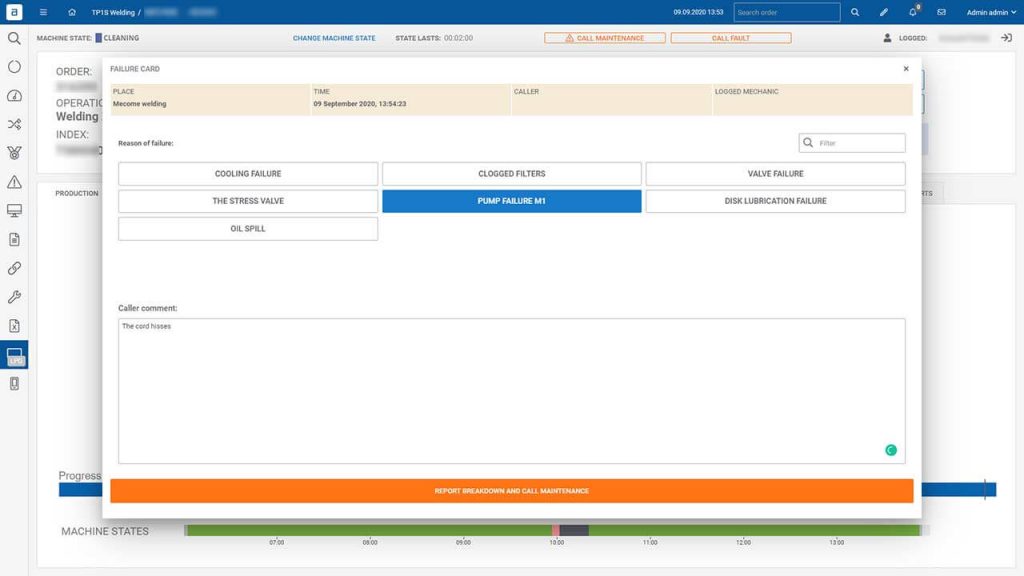

Maintenance ANDON

Finally alerts on time

Maintenance ANDON supports communication between the production and maintenance department. Operators report failures digitally with its reason and comments. All done maintenance history with knowledge is being kept in the system. The system monitors reaction times and presents dedicated reports with MTTR, MTBF and MTTF.

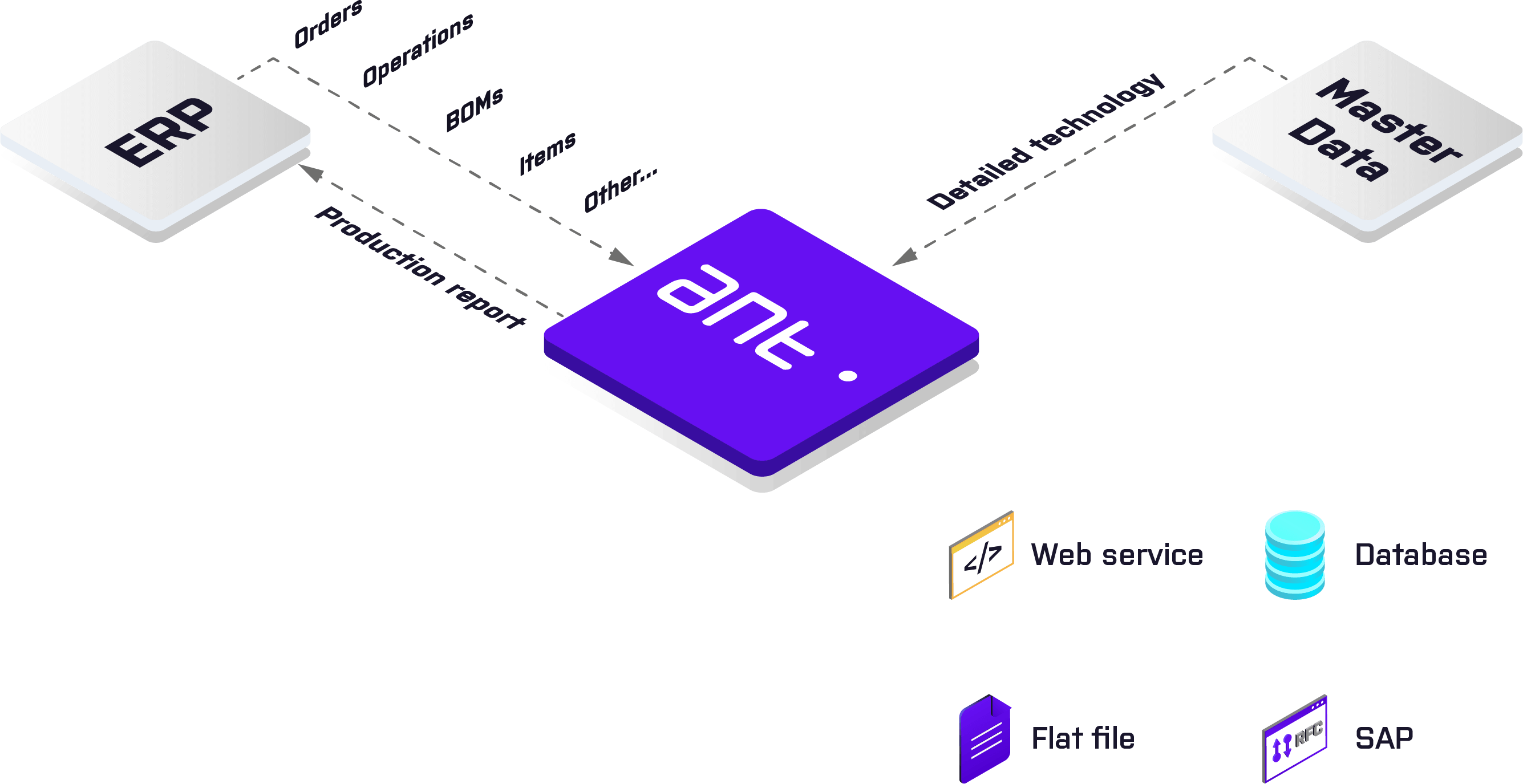

System Integration

Stop the double work

System Presentation

Contact with our Expert

Why to get a demo?

- A 60-minute online meeting with a dedicated specialist presenting a top system from an industry similar to yours

- Live modeling of your production process

- A budget quotation after the meeting

Related articles

Why does OEE drop after MES implementation?

After the implementation of MES, we usually notice a strange effect. In most cases, after the system go-live, the OEE coefficient is lower than before the installation.

How to increase production transparency on the factory shopfloor?

Transparency in manufacturing may sound like a marketing ploy, but it actually brings tangible benefits, from smoother workflows to significant financial savings. If transparency in

How does MES solution eliminate paper from production and shopfloor?

Digitalization has firmly established itself in everyday production processes, regardless of the industry. Nevertheless, habits remain from the days before widespread digitalization, traditional solutions not

Operational efficiency, or OEE, is an indicator that measures production efficiency for an organization. It is a measure that shows how well an organization is doing in terms of productivity, quality and equipment availability. The three main components of this indicator are productivity: the number of products produced per unit of time; quality: the number of defective products per unit of time; and availability: the number of available machines per unit of time. Existing formulas for OEE, allow a simplified way to calculate the efficiency of a line in a given plant.

There are many factors that affect the OEE of a manufacturing process. Some include an unstable process, excessive downtime and lack of reliable KPIs. Others relate to the human factor, where untrained operators can slow down the changeover process or cause additional defects. The list of factors is long, but all of them can be eliminated through efficient implementation of modern measurement technologies and improved production processes on the manufacturing line.

Overall Equipment Effectiveness Performance Monitoring

Connect and gather data from your machines. Start monitoring OEE that is calculated automatically and based on the machine’s signals. Begin production monitoring, its progress, efficiency and make decisions based on actual data.

3 main benefits:

- Faster production reporting with monitoring production in real-time

- Higher production volume thanks to faster production launch, fast defects and downtimes escalations

- The increased machine’s availability thanks to faster maintenance reaction time

What is OEE (Overall Equipment Efficiency)?

What is OEE and what it depends on? OEE, or Overall Equipment Efficiency, is an indicator used to measure the efficiency of managing the capabilities of equipment used in manufacturing plants. The aim is to make maximum use of the available machine time to manufacture products of the best possible quality. OEE is made up of three different factors.

- Availability – the ratio of planned working time to actual time taken to complete a task. Availability is reduced as a result of breakdowns, micro-downtimes and the time needed for changeovers and machine set-up.

- Performance – the ratio of available time to actual working time. Performance is reduced when the speed of operations is lower than assumed.

- Quality – the ratio of the number of good products suitable for further distribution to all components manufactured.

The aim of businesses is to achieve and maintain the indicator at the highest possible level. Average companies manage to achieve an OEE of around 60%. The best-organised companies can boast a score of around 85%, with the greatest attention always focused on the best possible quality factor.

What can you do to be among the most effective plants? The first step to understanding the productivity level is to start measurements. How to monitor OEE automatically in real-time?. The solution is OEE software. OEE software is a modern system whose task is to constantly monitor all processes that take place on the production line. How is the overall equipment efficiency (OEE) measured? After connecting to the devices, OEE system collects information about the real time of the cycle, enables an accurate description of the machine states during the shift, and defect reporting (manufactured items are OK / NOK). Based on these data, the OEE is calculated. The OEE system indicates things to improve and sends notifications in real time.

Where is OEE software used?

OEE software is widely used in manufacturing. It is used by the electronics, automotive, aviation, pharmaceutical, cosmetics and machines industries – in these and many other industrial plants, manufacturers welcome the use of OEE. MES, the manufacturing execution system, also takes this data, collects and uses it for further analysis, which improves processes and increases the efficiency of the production process. MES collects more information about the process and allows to manage the reworks. The qualitative data are necessary to generate SPC reports. MES also enables paperless production and traceability. OEE tracking software is one of the most fundamental investments being made by modern businesses.

OEE ratio monitoring

How does the OEE monitoring system work? Machine Connectivity connects the machines to the plant’s internal network. The data is read and processed by OEE software. Production Execution allows the monitoring of production plan execution in real-time. The system checks the production progress on an ongoing basis, and thanks to Defect Handling, it can also report faults. The system will show the cause of these defects. OEE Analysis module shows KPIs along with availability, performance and quality. This information allows you to establish overall equipment efficiency and then the action plan for your production facility. The obtained score of overall equipment efficiency (OEE) indicates whether the current production process allows achieving maximum efficiency, or whether some aspects need improvement. Thanks to Digital Documentation, all documentation is paperless and all messages are displayed on machine monitors. The Maintenance ANDON module allows you to quickly and easily communicate with the maintenance department. Digital communication as well as a history of faults and actions taken are stored in the system.

And how does the OEE system know what the highest possible machinery effectiveness is? The client decides what standard of OEE will be satisfactory and how exactly he wants to calculate it.

There is another major advantage that OEE software provides – the manager gets information about irregularities in real time and knows the current overall equipment efficiency (OEE). There are no delays due to the delivery of paper documentation, and access to reports is remote. As a result, it is possible to react in time to complete the production plan on time.

OEE allows not only a quick overview of processes running in real time but also of those that have been already completed. In this way, it is possible to check whether a failure has occurred, how quick the response time was and what the cause of the downtime was. By comparing current and historical orders, the trend of OEE can be checked to know what is causing productivity to decline.

OEE system – possible integrations

OEE Performance Monitoring is not just about checking one indicator. Growing businesses benefit from a comprehensive range of manufacturing management systems. The systems can be integrated with each other. OEE effectively exchanges data, especially with ERP system.

What for? By integrating the systems, you will avoid double reporting involved in downloading data from several programs. Each of them is connected to the main system, receives the same information and uses it in a specific way. Additionally, it can analyse the information and exchange it with the rest of the network.

Your OEE – benefits for your company

OEE software enables the collection of correct production data and tracking the condition of machines and the progress of production in real-time. Each factor that could delay production is notified. The collected data and generated reports indicate areas that require improvement for production to proceed as planned. It ensures that overall equipment efficiency is maintained at the highest level.

By achieving high OEE, overall equipment is utilised in the plant in the most optimal way and the shop floor of customers is filled with full-quality products delivered on time.

This is what causes your factory to start ignition. OEE builds the image of a perfect supplier.