Advanced

Planning & Scheduling (APS)

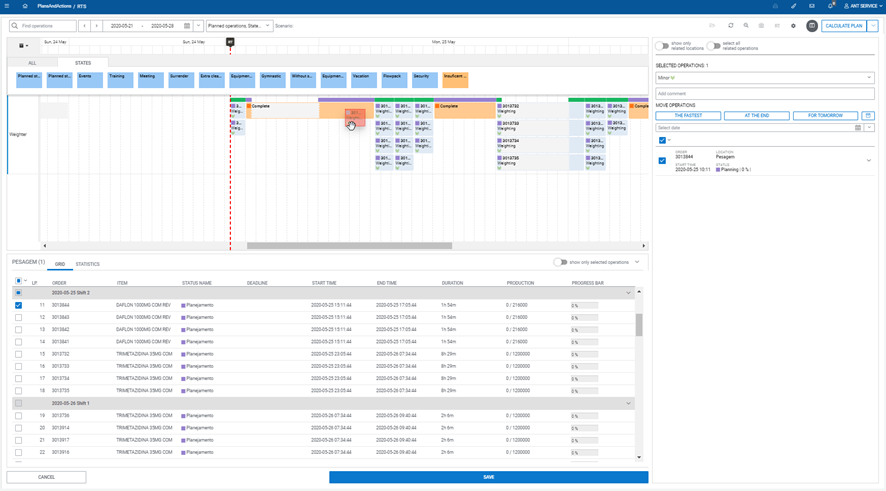

Planning and scheduling production is made more accessible with ANT's APS software. Maintain a constant production pace with the help of an advanced algorithm. Use a drag-and-drop interface to automatically reschedule plans and introduce more realistic plans thanks to real-time cycle information based on historical data.

APS - plan precisely, execute on time!

In the supply chain, you can always expect the unexpected. Delays in the delivery of materials, sudden staff shortages or machine breakdowns can turn production on its head and chaos begins to reign on the shop floor. Thanks to APS, such a scenario will never happen again in your plant. The system will not only allow you to plan production, but also optimize the course of processes based on data collected in real time. What is APS and how does it work? Find out how this state-of-the-art precision planning software allows you to optimize process execution time and efficiency of production resources!

APS system - what is it and how does it work?

APS (Advanced Planning and Scheduling) is an advanced tool that is indispensable in the proper scheduling of any manufacturing plant. What exactly is an APS system? The software makes it possible to plan processes taking into account available resources based on information found in integrated systems. The advantage of APS over other systems is that it analyzes data in real time and adjusts the schedule to the current capabilities and needs of the plant. There is also an option for manual modifications. APS responds to changes in real time, and allows prioritization of tasks and planning of different scenarios to choose the best solution.

Advanced Planning and Scheduling (APS) by ANT is equipped with modern AI which automatically recalculates all production data and predicts future production. It is an artificial intelligence-based system that can be programmed to work in the background, without human intervention.

The APS system predicts the future by taking into account information from machines’ plc, past data, stops, errors, delivery issues, repairs and more. If the APS system is connected to ERP, CMMS, WMS, or other factory systems it fetches and analyses data from multiple sources before making a decision.

Scheduling is a key component of production optimization. It plays a role in better time management, on-time delivery and resource optimization. APS can be used to handle the entire scheduling process – from order confirmation to the production process, thus ensuring that all orders are confirmed and scheduled in a timely manner so they can be delivered on time.

It also helps optimize production by informing managers of bottlenecks on their production line and suggesting ways to improve them.

3 main benefits of using APS in production:

1.

The production is predictable. Using APS in production optimizes changeover times. It also enables better utilization of resources and lower inventory levels – good planning eliminates the need to stockpile a large amount of materials. The plant is able to use resources on an ongoing basis without worrying about shortages or excesses, which is an important aspect in cost optimization.

2.

Precise scheduling makes production processes predictable. This gives management confidence and a sense of security – in emergency situations, the software guarantees certain and proven results. It also indicates the advantage of automated solutions. In such a dynamic environment, mathematics reacts to changes, and the possibility of erroneous calculations made under the influence of human emotions or haste is eliminated. The key benefit of this solution is therefore to improve the efficiency and quality of processes, and thus increase OEE.

3.

The APS system also proves its worth when taking orders. Data from a potential customer can be quickly entered into the system to see if the plant will be able to fulfill the order and by what date the order will be ready. The customer receives a quick, accurate and reliable response. The ability to plan for the long term increases the chances of winning more orders and is an excellent way to stay ahead of the competition. The timely execution of orders made possible by precise planning at APS also influences better relations with contractors.

Results achieved by Clients:

Higher

production volume

Shorter

changeovers

Less

total changeovers

According to our clients, the implementation of the ANT APS system has allowed them to:

- eliminate the time needed to manually update the plan progress

- replace two-shift production with a single shift and ensure on-time deliveries at the same time.

- maintain on-time deliveries while dynamically changing priorities

- eliminate situations in which production could not be started and completed due to a lack of people, materials, or tools

What are APS key functions?

The extensive functions of the APS system allow to influence the functioning of the entire production plant. Starting from the reception of raw materials to the dispatch of goods to the clients.

Production process overview

Manual and automatical optimization

Collisions prevention, notification about impossible scenarios

Additional objects to plan: maintenance, changeovers, non production time breaks, other

REAL-TIME PRODUCTION UPDATES

Plan reality and expect a proper production volume. With real-time production updates, your work will be simpler. The system automatically calculates and adjusts production times, machine occupancy, and predicts time for repairs and defects. The calculations are based on actual and historical data with a help of advanced AI, which can predict the necessary time spaces.

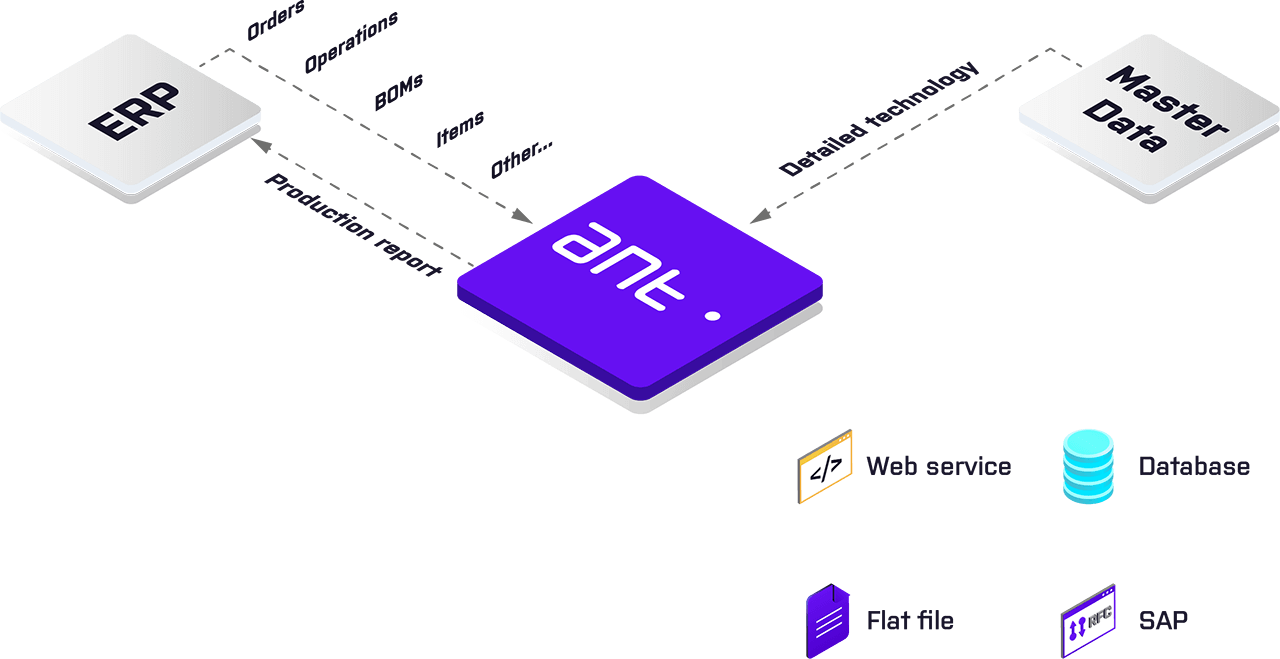

Modern and automated production planning requires new tools for more efficient use of available data. The built-in algorithms developed by our team allow a smooth exchange of information between cooperating systems, while the APS system itself plays the role of coordinator in the supply chain.

Item definitions are pulled from a master database of records (Master Data), allowing work on verified data. In addition, the templates can be further modelled in the system.

At the same time, ANT APS pulls data from any ERP system (SAP…etc.) sending updated reports so that all information between company departments is oriented on production progress.

The current production status is continuously uploaded and analyzed by algorithms, and the real-time production plan is sent to the production floor, allowing you to get an idea of the progress and plan tasks if necessary.

How to optimize production plan?

Nowadays, production planning requires particular precision, operating in real time and updating objectives in relation to the current state of the machines.

CHANGEOVER MATRIX

Modern and automated production planning requires new tools for more efficient use of available data. The built-in changeovers matrix, steps, progress and time monitoring allows for more predictable planning and work with the maintenance team.

In addition, algorithms developed by our team allow a smooth exchange of information between cooperating systems, while the APS system itself plays the role of coordinator in the supply chain.

Advanced Planning and Scheduling - respond to changes in real time

APS is currently the most precise tool that modern factories can use when scheduling production. The software’s advantage lies in making modifications to the schedule based on data generated in real time. The flexible program not only plans production accurately based on historical data, but also responds to market and process dynamics and current resource information. A message about a delay in the delivery of goods, a machine breakdown or a shortage of employees no longer leads to chaos on the production floor. APS instantly adjusts the course of processes to the needs and capabilities of the plant. If there is a change in priorities or the amount of resources, the system re-schedules production for an optimal solution.

Reacting to ongoing changes is what differentiates planning in APS from using less sophisticated systems such as ERP, for example. Only APS allows you to re-schedule production automatically and instantly based on data pulled from integrated systems. Even in the event of an unexpected shortage of resources, the APS system creates an optimal production plan focused on achieving the best possible efficiency.

Increase your resource efficiency with ANT APS!

When choosing a solution for advanced planning and scheduling of production processes, it is worth betting on software provided by a proven supplier. The APS ANT system was created by specialists with many years of experience, and its effectiveness is constantly confirmed by the increasingly better results achieved at our customers’ plants. Our own source code makes us independent of external entities and allows us to tailor the system’s functions to the needs and capabilities of a specific plant.

Do you want to improve the efficiency of your production processes? Are you looking for a solution that will allow you to meet your contracts in a timely manner, as well as prevent potential problems early on? We will make your plant’s processes predictable. Contact us to learn more about system implementation. Use your plant’s full potential and create an optimal production plan in real time with ANT APS!

System Presentation

Contact with our Expert

Why to get a demo?

- A 60-minute online meeting with a dedicated specialist presenting a top system from an industry similar to yours

- Live modeling of your production process

- A budget quotation after the meeting

Related articles

How to optimize production plan?

Nowadays, production planning requires particular precision, operating in real time and updating objectives in relation to the current state of the machines. Only on this

How to make your meetings on the shopfloor more efficient?

Meetings on the shopfloor are pretty much an everyday occurrence and are essential to keep things running efficiently and effectively. The type and quantity of

Production planning in APS as a method for reacting rapidly to process dynamics

The APS system is an advanced tool for planning production and responding to events occurring in real time. Integration of the software with other management