SHOP FLOOR Warehouse

management

system (WMS)

Inventory monitoring for shop floor warehouse

Shop Floor WMS system - manage your warehouse efficiently!

Maintaining a competitive position in the market in the era of Industry 4.0 requires the use of technologically advanced solutions. Specialized tools support shop floor warehouses in achieving better and better efficiency indicators. A Shop Floor WMS allows you to remotely manage your shop floor warehouse, supervise the implementation of processes, detect sources of irregularities and monitor the operation of the plant in real time. Find out exactly what a Shop Floor WMS is and see how the modern software developed by ANT works!

What is

a WMS system?

A Shop Floor WMS (Warehouse Management System) is specialized software for efficient warehouse and inventory management. The IT system allows you to collect data, check the correctness of processes, supervise their efficiency, instantly detect irregularities, as well as track products and identify events in real time.

ANT WMS provides users with easy interface and real-time stocks updates to manage shopfloor warehouse by identifying right products and their location. Ship goods and deliver parts just in time to streamline the production process.

The cost of a WMS can vary depending on the features and functionality you need. The price also largely depends on the size of the client and the number of external integrations. In addition, in order to price the implementation, the vendor team must assess the current state of the facility and bring it up to system standards, making the WMS implementation feasible.

There are many factors that affect the length of the WMS implementation process, such as the size and complexity of the company, as well as additional needs specific to the entity, but on average it takes about 3 months to implement a WMS from start to finish. Implementation time can be shorter if there is no need for customization or integration with other systems.

How does the Shop Floor WMS system work?

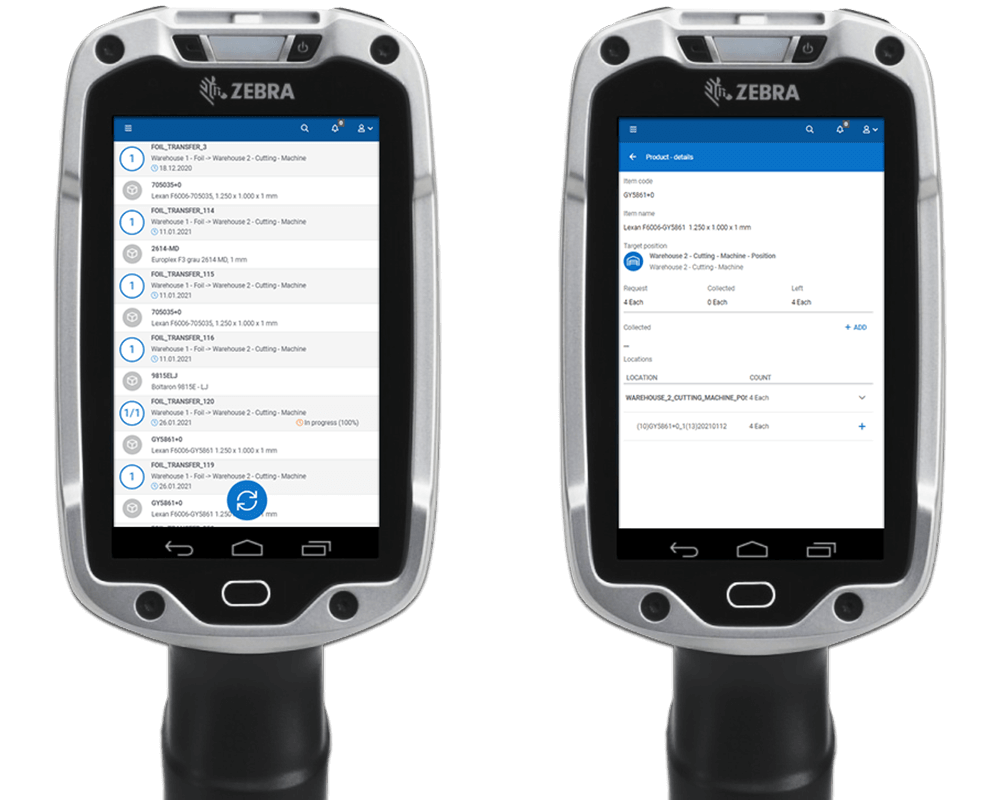

ANT WMS uses traceability, or automatic identification technology, to record events in real time. Data acquisition in the form of status, location or product details is possible after scanning a 1D, 2D or RFID barcode tag. It provides a vehicle for product information such as serial number, location, path or a list of operations performed so far. This information can also be collected for multiple warehouses, making the entire product history available in one place.

The warehouse management system allows inventory monitoring. Location records provide instant information on the amount of available space in storage areas. The WMS collects data on logistics containers – the user is able to see what products are assigned to a particular container, and can add or remove container contents or parts of them. It is also possible to carry out relocations of products and entire containers. Each relocation is registered. This means that despite numerous relocations, the current location and path of products and containers is always known.

The program guides employees during the execution of subsequent processes, making work much easier and faster. The intuitive interface includes clear instructions and graphics displayed on device screens.

- add new products to the warehouse during the goods receiving process

- simple input data in the form or by scanning

- choose the position on warehouse

- auto print QR code for identification

How does the WMS system work when monitoring employees?

The software collects data on operations assigned to the ID of a specific user. This provides information on current activities and tasks completed so far. The collected data makes it possible to carry out an objective evaluation of employees based on precise data about their performance during the accounted period.

ANT WMS works on mobile devices, allowing remote access to all information on warehouse operations collected in one place. The software eliminates the need to store data in piles of paper documentation. Based on the collected information, it is possible to create detailed reports.

How does the Shop floor WMS system improve warehouse operations?

The ANT WMS system allows you to manage stored products from the moment they are received until they leave the warehouse.

During unloading, the warehouse management system collects information about the delivered goods – their type, quantity and compliance with the order. A shortage or excess is immediately registered. At the goods receipt stage, the WMS allows to assign a location. The collected data is used to optimize the order picking process and set a path so that products can leave the warehouse as quickly as possible. If problems arise at the packing stage due to damaged or missing products, the ANT WMS will allow you to find a replacement in no time and ship the complete shipment as planned.

Fast goods receiving process

Ensurance to have identification on the admissioned products

Guiding operator through the process

What are ANT WMS functions?

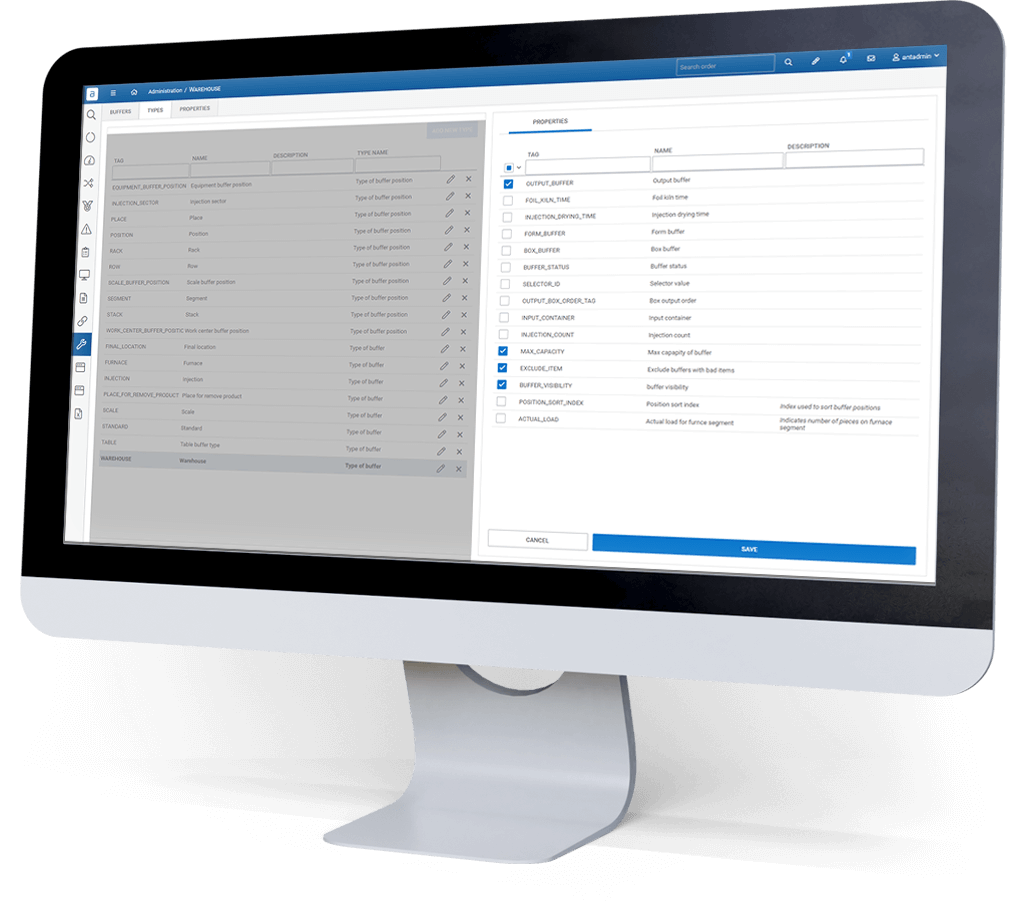

Warehouse System Structure

The system allows you to define your own warehouse structure with its levels: racks, locations, positions. Custom properties of warehouse types and levels can be set to model business processes. Configuration for managing acceptable product flow between warehouses is also available.

Goods Receipt Process

When receiving goods into the warehouse from an external supplier, the system records all incoming goods, automatically prints a label for each batch, and proceeds to transfer the goods to the warehouse and its location. The system monitors the progress and completeness of the order (PO).

Buffors

Monitor where products are stored, the current inventory and an overview view for all warehouses. Information about the occupation of each level, the contents of containers or the serial number of goods.

Warehouse Movements

Change the location of a scanned container or serialized product. The user can split the movement, taking only a part of the goods in the scanned location. The system allows the user to move goods only to other locations according to the established warehouse flow. The user can make multiple moves during a single transaction.

Internal & External Shipments

An automatic mechanism between MES (in production) with WMS. Material supply requests are created and managed at the warehouse according to a prepared list. Materials are collected from suggested locations. Progress is monitored at all times.

Mobile devices

The system works on mobile devices which allows you to access data in real time by scanning any location, container or product (S/N). You can use a mobile device to perform processes such as receiving goods, internal and external shipment of goods, or warehouse movements.

Label Printing

The user can manage and create new labels in the system. Labels can be customized by the user with assignments to individual items or customers. Labels can be set up to be printed automatically, for example, during receiving or shipping.

Containers

Manage containers with their location and status. The user can view the contents of a container and change its status, move products to other containers or remove products from a container. Support of container repacking process.

WMS in logistics - why should modern warehouses implement it?

Implementing a WMS in logistics is an effective way to keep warehouse structures in order. Despite the implementation of numerous processes, the information collected by ANT WMS allows you to quickly find the necessary data. The software also provides effective support in solving problems – thanks to a clear history, you can instantly locate the cause of irregularities and prevent them in the future.

A dedicated solution allows you to create a personalized structure tailored to the current needs and capabilities of a specific plant. The warehouse management system can be integrated with other IT systems such as MES or ERP. Efficient communication and constant access to current data translate into an increase in the efficiency, productivity and quality of processes, thus enabling the timely implementation of the set objectives – this in turn is one of the key elements in building positive relationships with contractors.

How WMS can be incorporated into your daily workflow?

The system works on shipping orders, which are automatically written out for the user. By scanning identifiers (containers or products with serial numbers), the system automatically checks whether the scanned goods are suitable for shipment. Thanks to this mechanism, only good parts will reach the end customer. The progress of the shipping order is monitored and visualized. The system prompts from which location to retrieve products. A shipment can be blocked and resumed only by an authorized user. Blocked goods can be moved to another location for further QC decision.

1. incoming from supplier

2. admission to warehouse – identification print for product

3. quality control and release to production

4. movement from warehouse to production

5. shipment with validation and VDA label print

6. shipment

Shop Floor Warehouse Management System - bet on a solution from ANT!

ANT is a proven provider of advanced technological solutions. We offer comprehensive implementation of a personalized WMS for smaller ,larger warehouses and shopfloors. Our own source code allows us to perform modifications to the system – our WMS will evolve with the growing needs of the company.

The knowledge and skills of a dedicated team translate into the effectiveness of customizable software. Our experts with years of experience have numerous successful implementations behind them.

Join the ranks of satisfied customers and achieve your goals. Contact us for more information about implementing a WMS in your facility. Increase the efficiency and quality of your processes and stay ahead of the competition with ANT WMS!

System Presentation

Contact with our Expert

Why to get a demo?

- A 60-minute online meeting with a dedicated specialist presenting a top system from an industry similar to yours

- Live modeling of your production process

- A budget quotation after the meeting

Related articles

WMS – how to choose a warehouse management system and how much does it cost?

A WMS is used to better control warehouse processes and increase efficiency indicators. In order to achieve the intended effect of improving the efficiency and

How to manage production by using modern shopfloor WMS and Autonomous Mobile Robots? (VIDEO)

Modern factories must constantly develop and raise efficiency indicators to achieve and maintain a strong market position. One of the ways to do this is