The only one reason why to invest in MES system for your production

As the world becomes more connected and businesses strive to become more efficient, the need for advanced manufacturing technology is becoming increasingly important. One of

MOM stands for “Manufacturing Operations Management”. It refers to a holistic approach to manufacturing and operation processes which includes the tracking and optimization of materials, resources, equipment, and people for the purpose of improving the performance of a supply chain.

A MOM system, is a type of production management system used to optimize and streamline the manufacturing process in various industries.

The system provides a centralized platform to monitor and manage various stages of production, quality, planning, maintenance activities and inventory management. MOM systems help manufacturers improve their efficiency, reduce production costs, and increase overall productivity. Its ability to automate and integrate different production processes makes it an essential tool for achieving operational excellence and remaining competitive in the global market.

The ISA-95 Pyramid, also known as the ISA-95 standard, is a widely recognized model that defines the different levels of automation and information systems in a manufacturing operation. The pyramid has five levels, ranging from level 0 at the bottom to level 4 at the top.

A MOM system fits into the 95 ISA Pyramid as a system that operates at level 3, which is the manufacturing operations level. At this level, the MOM system integrates with the control systems that operate at the lower levels of the pyramid (levels 0-2) and provides a bridge to the higher levels of the pyramid (level 4).

At level 3, the MOM system manages the manufacturing operations by collecting data from the lower levels and using it to monitor and optimize the production process. The system provides tools for production planning, scheduling, and execution, as well as quality management, maintenance, and inventory control. It also collects data on production performance and provides real-time monitoring and reporting.

Yes, there is a difference between MOM (Manufacturing Operations Management) and MES (Manufacturing Execution System), although the terms are often used interchangeably.

MOM is a broader term that encompasses a range of systems, including MES, which is a subset of MOM. MOM refers to the entire set of software applications used to manage and optimise manufacturing operations, while MES is a specific type of software application within the MOM that focuses on managing the execution of production processes.

Sustainability management (enrgy consumption, carbon footprint etc.)

AI-driven optimisation

Edge data collection

✔️ digital forms filled automatically

✔️ modelling process workflow

✔️ steps divided for roles

✔️ deviations recognizing

✔️ microstops detection with auto name

✔️ algorithm to find root causes

✔️ MTBF analysis per machine/item

✔️ sending recipies on the fly

✔️ centerlining

✔️ operator guidance

A Manufacturing Operations Management (MOM) system can lead an organisation towards operations excellence by improving the efficiency and effectiveness of the manufacturing process. MOM systems provide a comprehensive solution for managing various aspects of the manufacturing process, including document management, historian reporting, scheduling/dispatching, asset tracking (traceability), and equipment health.

Document Management: MOM systems provide a centralised platform for document management, allowing manufacturers to manage and control critical production documents, such as work instructions, standard operating procedures (SOPs), and quality documents. By ensuring that the correct documents are available to the production teams at the right time, MOM systems help to minimise errors and improve compliance.

Historian Reporting: MOM systems provide real-time data collection and reporting capabilities, enabling manufacturers to track and analyse production data in real-time. The historian reporting functionality provides a comprehensive view of the manufacturing process, allowing managers to make informed decisions and quickly identify areas of improvement.

Scheduling/Dispatching: MOM systems provide tools for production planning, scheduling, and dispatching, ensuring that production runs smoothly and efficiently. By automating these processes, MOM systems help to minimise downtime, improve on-time delivery, and optimise production resources.

Asset Tracking (Traceability): MOM systems provide a complete solution for tracking and managing production assets, from raw materials to finished goods. By enabling manufacturers to track materials and finished goods throughout the production process, MOM systems help to improve traceability and quality control.

Equipment Health: MOM systems provide tools for monitoring and managing equipment health, enabling manufacturers to identify and address equipment issues before they result in downtime. By optimising equipment maintenance and reducing downtime, MOM systems help to improve production efficiency and reduce costs.

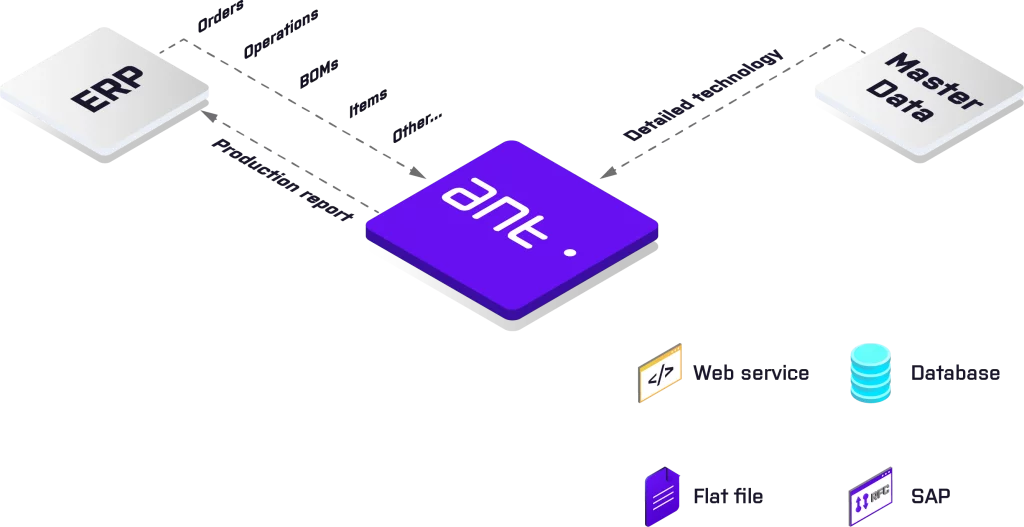

ANT is an independent software provider for modern manufacturing. Our solutions are designed to make production facilities more flexible, adaptable, and efficient. The software enables real-time visibility into your operations and facilitates collaboration between people, data, and systems so that you can spend less time on operational tasks and more time on innovation.

As the world becomes more connected and businesses strive to become more efficient, the need for advanced manufacturing technology is becoming increasingly important. One of

What is Effective Production Monitoring? Effective production monitoring refers to the systematic tracking, analysis, and management of various aspects of the manufacturing process to optimise

Machine data acquisition software is a tool that enables the collection, storage, processing and visualisation of data from machines and equipment. This data can be

The short answer is yes, you can also download data from an old machine. In many cases, the older machine under analysis does not have an Ethernet port and it is not possible to use a USB cable to connect the machine to a PC. The most common solution is to get around this problem by duplicating the analog signal to digital or installing additional sensors or cameras that will count successive cycles or batches of production.

Production data management systems are often used in the cloud because of their ability to scale with the business. It is important that the cloud provider has a high level of security and reliability. The answer is yes. In the cloud, MOM System can run more efficiently and reliably with less downtime. Some of the benefits of using a PDMS in the cloud include: Reduced upfront costs – Scalability and flexibility – Reduced IT infrastructure costs.

Download Return of Investment (ROI) Document in Molding Injection Machine Industry