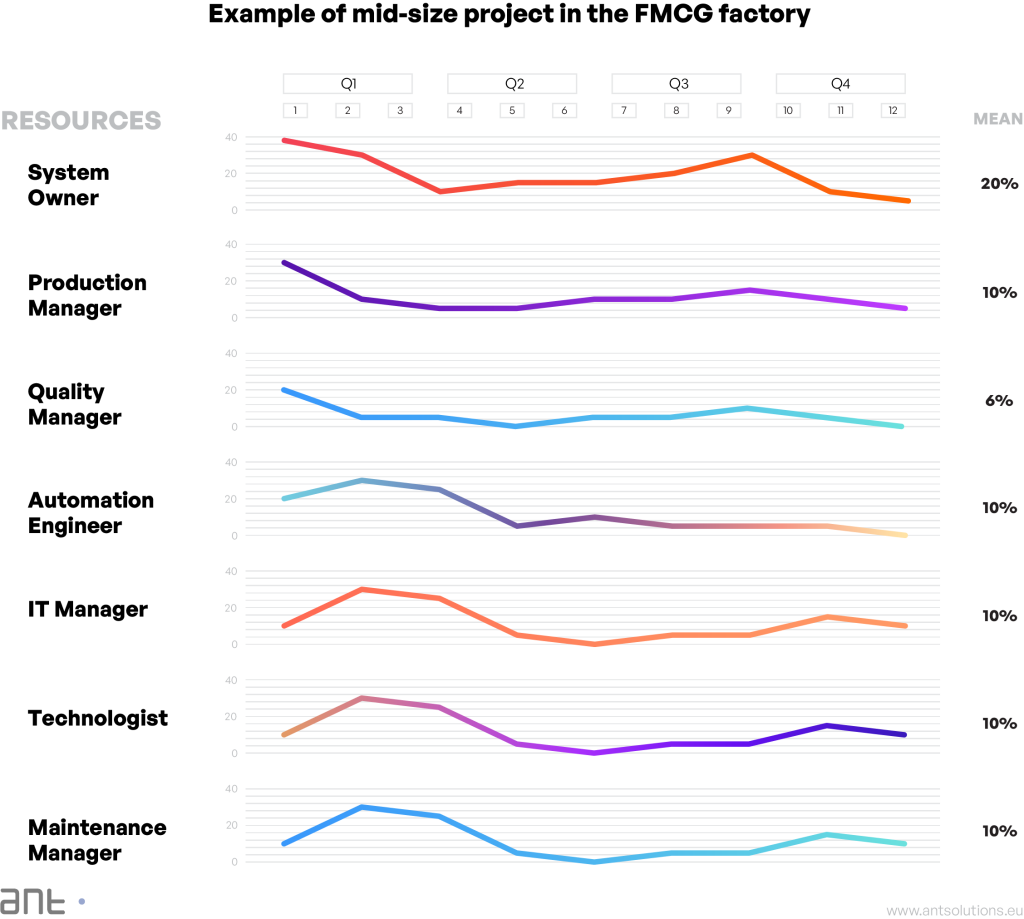

Integration of all production processes – discover the possibilities of the Smart Factory

The Smart Factory meets the objectives of Industry 4.0 through the traceability and communicability of objects, the networking of machines and equipment, as well as