Paperless MANUFACTURING

Create a green enterprise with ANT PAPERLESS MANUFACTURING digital documentation. Use digitized forms and streamline communication in your company. Access all your data from anywhere.

Paperless Production in the Era of Industry 4.0

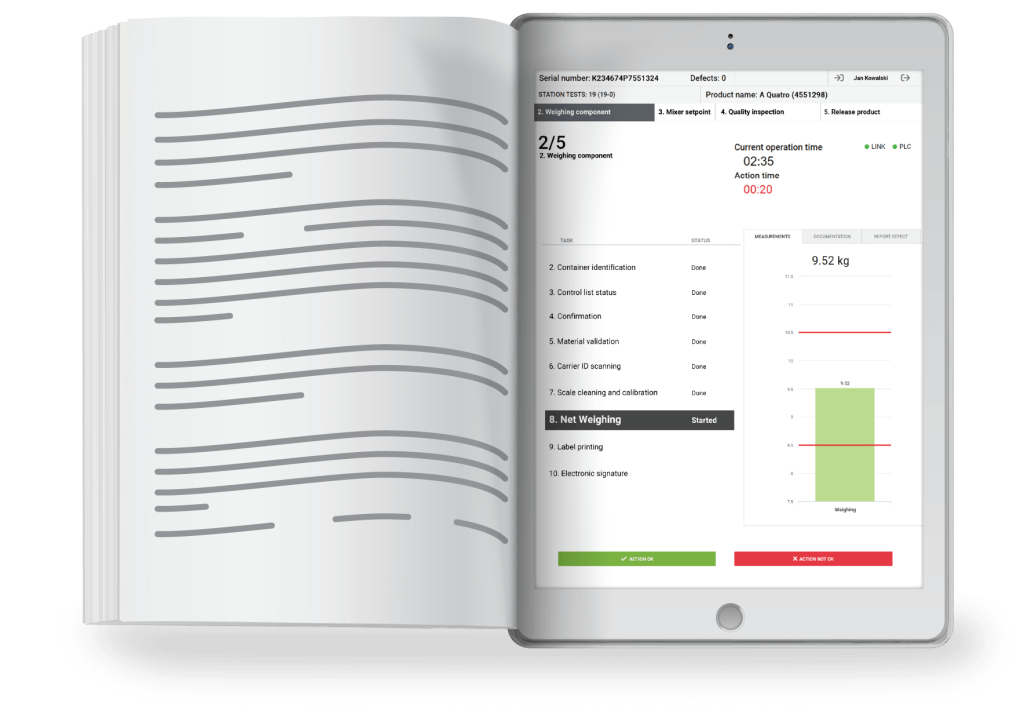

Paperless is responsible for digital guidance of operator – starting from displaying activities (list to-do) for production, changeovers with dedicated documentation (image, document, movie) for each step of production. Any paper form can be transferred to the system thanks to Factory Forms and all step for production are being kept as Electronic Batch Records.

Paperless - what does it mean and why is it important to implement paperless manufacturing?

Paperless production means eliminating the standard form of documentation in favor of its digital counterpart. Electronic archives, signatures and correspondence are replacing tons of paper files. Eliminating paper in production processes is now not just a popular measure, but a necessity.

Paperless policy in environmental protection

Environmental aspects have had a huge impact on the widespread promotion of paperless policies. The cost of paper production is high, and the sourcing of this material is not indifferent to the environment. According to reports prepared by world-class experts, the felling of trees and the carbon footprint caused by misuse of resources contribute to climate change. We are also increasingly experiencing problems with the availability of paper – it happens that resources are very limited in emergency situations. At the same time, as part of environmental measures, plastic packaging is being eliminated from the market in favor of paper packaging, so it is worth reducing paper consumption where it is feasible – for example, in the company’s documentation workflow.

Paperless policy essential to company growth

Paperless production brings tangible benefits to companies in the form of increased productivity and process quality. Digital transformation is one of the key ways to realize the concept of Industry 4.0. Reducing paper documentation and moving it to a digitized form allows to increase efficiency and the quality of communication and processes, as well as to build a competitive position in the market. Indeed, current trends in the economy point to a reduction in printing in favor of digital transformation.

Why ANT Paperless Manufacturing?

Time reduction

Improved Data Quality due to automation

Standarization – (never skip a task)

Automated validation

Learn 7 reasons to go paperless

EBR Reporting

1.

streamline your workflows

2.

become more environmentally friendly

3.

rely on reliable data

4.

implement a digital documentation workflow

5.

gain instant access to information

6.

reduce data update time

7.

eliminate delays and errors in reports

Run paperless production processes!

Eliminating paper documentation helps build the image of an environmentally-conscious company, which is especially important for industrial plants. Digital transformation makes it possible to meet ever-higher quality and efficiency standards, which in turn contributes to the company’s competitiveness in the market.

Measurable benefits for an environmentally friendly factory

● Fast and efficient communication

● Structured current and historical data

● Instant remote access to necessary information

● Effective fulfillment of obligations related to the availability of documents subject to external audit

● Quickly make updates to documentation

● Saving space and costs associated with the preparation and storage of documentation

● Reduction of documentation errors due to the human factor.

● Faster data analysis thanks to the ability to present data in the form of easy-to-read charts or dashboards

● Reduce the company’s carbon footprint

● Dealing with the paper-constrained crisis.

● Preparing the factory for the challenges of increasing digitization and fluctuations in the availability of raw materials

Paperless – how it works?

- Convert paper reports to electronic versions

- Collect real data automatically from MES system

- Generate charts automatically with real-time data feed

- Monitor team’s tasks and their progress

Paperless as BPM class tool orchestrating activities

in ANT MES

Process

Standardize, automate, and digitize business processes. Map customer activities directly into process models, integrating with other systems and services as needed, and collect and connect business data through process flows. Designed in Process Modeler.

Forms

Describe the actions available and the consequences of activities in different contexts, such as handling operations in MES system, taking data from devices or human system mediation. Designed in Forms Builder.

Decisions

Comprehensive set of digital tools to help model dynamic and complex scenarios that respond to business needs (decision tables, formulas, loops).

Process Reports

Reporting of activities performed by specific users within defined processes (audit trial)

Output Reports

Set of business reports (batch reports) based on data collected during processes (e.g. EBR, quality data)

Sign up to our newsletter

Create an environmentally friendly factory with ANT PAPERLESS MANUFACTURING!

ANT PAPERLESS MANUFACTURING is specialized software prepared by high-class specialists. We develop technological solutions for industrial plants – smart factories and warehouses. Our system allows companies to implement a paperless policy and create an environmentally friendly enterprise. Proprietary source code, a staff of qualified experts and years of experience make us implement customizable software tailored to the needs of a particular company in our customers’ plants. Are you looking for a personalized system to move your documentation workflow to digital form? Contact us and we will provide an offer tailored to your needs!

System Presentation

Contact with our Expert

Why to get a demo?

- A 60-minute online meeting with a dedicated specialist presenting a top system from an industry similar to yours

- Live modeling of your production process

- A budget quotation after the meeting

Related articles

MES in Cosmetics help to reduce waste

Production optimization and related analytics is important for all businesses, regardless of industry. However, there are companies with special characteristics. This group includes, among others,

How to get automatically reports from production

Digitalization means that reporting in its traditional form, as we have known it for years – in paper form, symbolically passed from hand to hand

Paperless production is a concept that emerged in the early 2000s and has since been adopted by many companies. It is a system where all documents are stored electronically, and there is no need for physical copies of any document. This eliminates the need for paper, ink, and other supplies required to produce physical copies of documents.

The benefits of paperless production are clear: it can reduce costs, improve data integrity and quality, increase efficiency, and reduce environmental impact.

The paperless production process is more environmentally friendly than conventional manufacturing. It uses less resources and has a smaller carbon footprint.

– Paperless manufacturing is cheaper and more efficient. It reduces the need for raw materials and energy consumption.

– Paperless manufacturing can help reduce greenhouse gas emissions by over 50% which will have a significant impact on the environment.

– Paperless manufacturing can lead to less waste which will save space in landfills and reduce pollution caused by incineration.