Machine Connectivity

Machine Connectivity is responsible for communication with machine’s PLC and devices, providing the real measurement from the machine for acquisition, processing and administration of data collected from automation level. With different acquisition methods, data like machine states, quantity or process parameters, as well as real measurement from the machine, are read. This is the key component of ANT’s Smart Factory solutions which allows us to precisely collect real data and create a data-rich environment.

How to automatically detect defects on machine?

Sometimes the easiest way is the most effective one. Each signal from machines is transported via Ethernet to the server or dedicated buffer devices. We consult with you what data from machines are the most important and valuable for you and your business. This is why we install sensors on the lines, install vision monitoring solution to monitor performance and quality. We use I/O modules and automation converters to get data from your shopfloor. If needed we collect data that are being send by the devices.

Our equipment is able to read basic data from machines or calculated based on sensors: cycle counter (produced piece), defect counter, cycle time, machine status (work, microstop, stop), line’s speed, single process parameters (weight, pressure, temperature, force), connection status and more.

In case of lost connection with the server data read from machines and devices is buffered for desired period of time.

Connections methods

PLC Drivers

Communication protocols

Data acquisition modules

Sensors

Digital signals

Analog signals

Energy Consumption meters

Cameras

What to look at when connecting machines on production to IT system?

When connecting machines on production to an IT system, there are several key considerations that should be taken into account. Firstly, the security of the system should be ensured by having strong authentication measures in place such as encryption as well as firewalls and other security measures. Secondly, it is important to invest in robust and reliable software and hardware to ensure the system is reliable and has minimal downtime. Connecting to an IT system also requires integration, so it is important to have a plan in place to ensure a seamless transition. It is also important to ensure that access is only given to authorized personnel and that the system is continuously monitored for any suspicious activity.

How to ensure a real measurement from the machine on production shopfloor?

To ensure accurate measurements from machines on the production shopfloor, it is essential to implement a quality control system of regular calibration checks.

Quality assurance must be taken seriously as it can have a direct impact on the safety and efficacy of the products being produced. To ensure accurate measurements, machines need to be regularly calibrated according to the manufacturer’s specifications. This can be done by a technician or an automated system, depending on the type of machine and its calibration requirements. Additionally, technicians should be trained to properly use the machines and ensure they are in good working condition. Furthermore, it is important to implement a system of regular checks to make sure all the machines are in line with their factory settings and that they are producing accurate results. This can be done by taking periodic readings and comparing them to the recommended values, as well as by regularly monitoring the machines to ensure they are in line with the manufacturer’s specifications.

How to get data from Siemens PLC?

The ANT platform is a powerful tool for communication between machines, and comes with a range of built-in protocols for two-way communication. These protocols include OPC UA/DA, Siemens TCP, Allen Bradley, ADS Beckhoff, MTConnect, Heidenhain, ModbusTCP, SRTP GE Fanuc, Ethernet IP, Euromap 63, and many more. With this protocol suite, users can quickly and easily establish secure communications between machines, allowing for the efficient sharing of data and information. By utilizing these protocols, ANT platform users can optimize the performance of their machines, ensuring fast and efficient communication.

Protocols we use

- Heidenhain

- ModbusTCP

- SRTP GE Fanuc

- Ethernet IP

- Euromap

- Serial Port Custom Protocols

- OPC UA/DA

- Siemens TCP

- Allen Bradley

- ADS Beckhoff

- MTconnect

- File-sharing

- OMRON

- Ethernet/PI

- ODBC

- WCF

- Web services

- TCP Custom Protocols

and 60 more...

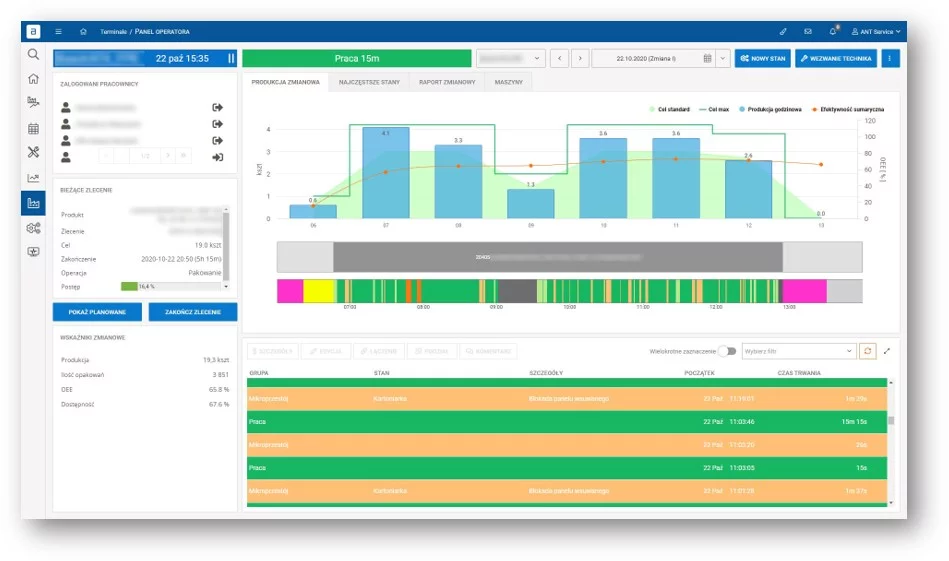

Operator panel

How the data is displayed?

Operator Panel supports shop floor employees in daily tasks. It is a basic dashboard providing all necessary data collected from the machine, displaying them in a colorful and meaningful way. Additional configurable options may allow different stakeholders to browse through the data in search of insight about the production or dig into the root cause of the stoppages or other detected problems.

Why choose ANT Solutions when it comes to machine connectivity in the factory?

ANT Solutions has been providing reliable and secure machine connectivity solutions for the factory industry for many years. Our solutions are based on a modular approach which allows companies to customize the platform to match their specific needs. We also make sure that signals collected from devices are authentic to give real measurement from the machine anytime. Furthermore, our services are secure, cost-effective, and are supported by a dedicated team of experienced professionals who are committed to providing excellent customer service. This makes ANT Solutions the perfect choice for companies that want to connect their machines in the factory.