Machine connectivity

Top machine connectivity solutions on the market. Collect production data in real time from all devices.

OEE, Quality Traceability

Precise OEE calculation and proven traceability solutions to keep production going with consistent quality.

APS

Plan and reschedule production with Advanced Planning and Scheduling software, designed to plan accordingly based on available materials in stock.

MES is a beneficial solution for the production of military equipment due to the provision of greater visibility of the progress of production orders and control over the entire production process. Implementing an MES allows monitoring and validation of materials, tracking of production operations and quality, and identification of areas for improvement.

The MES also enables more efficient production management. By providing real-time data, manufacturers can quickly detect areas of inefficiency and take corrective action to reduce waste and improve production efficiency. This can have a particularly large impact on military productions, where specific procedures are required to produce high quality and safe products.

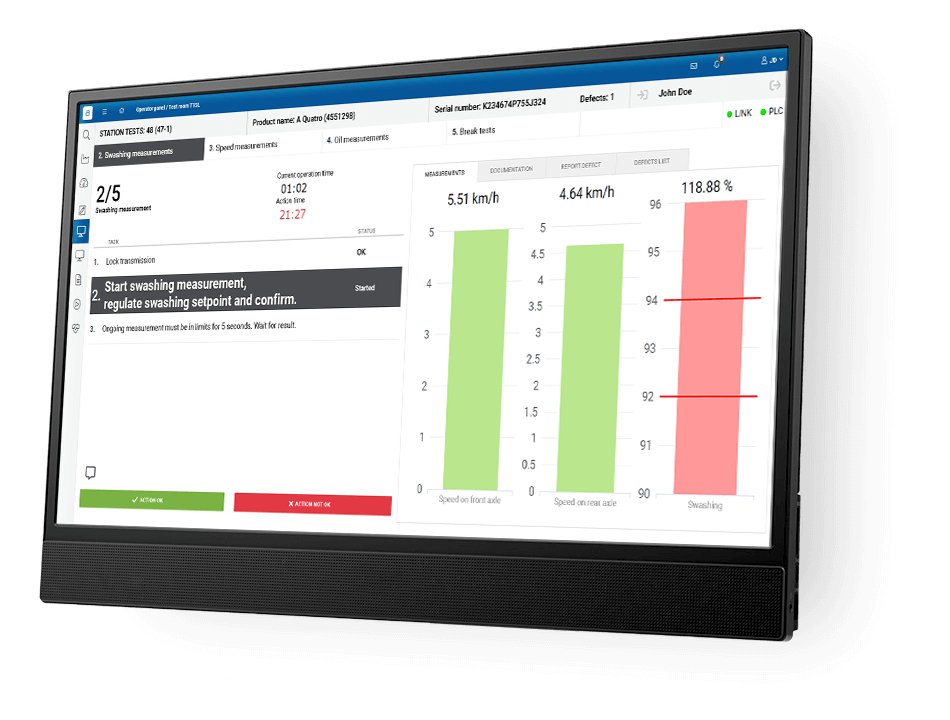

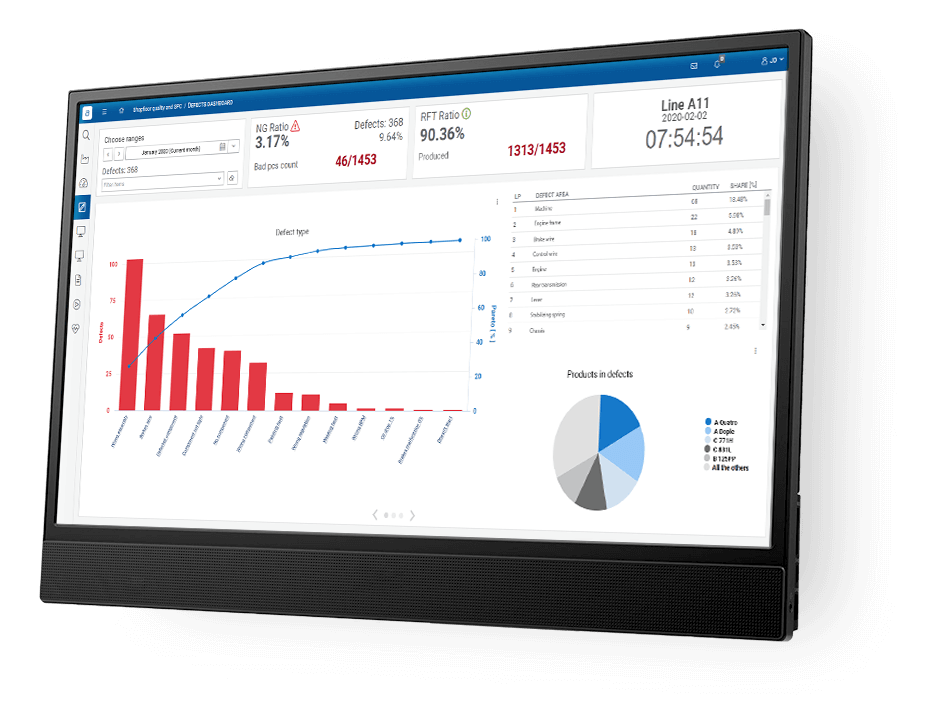

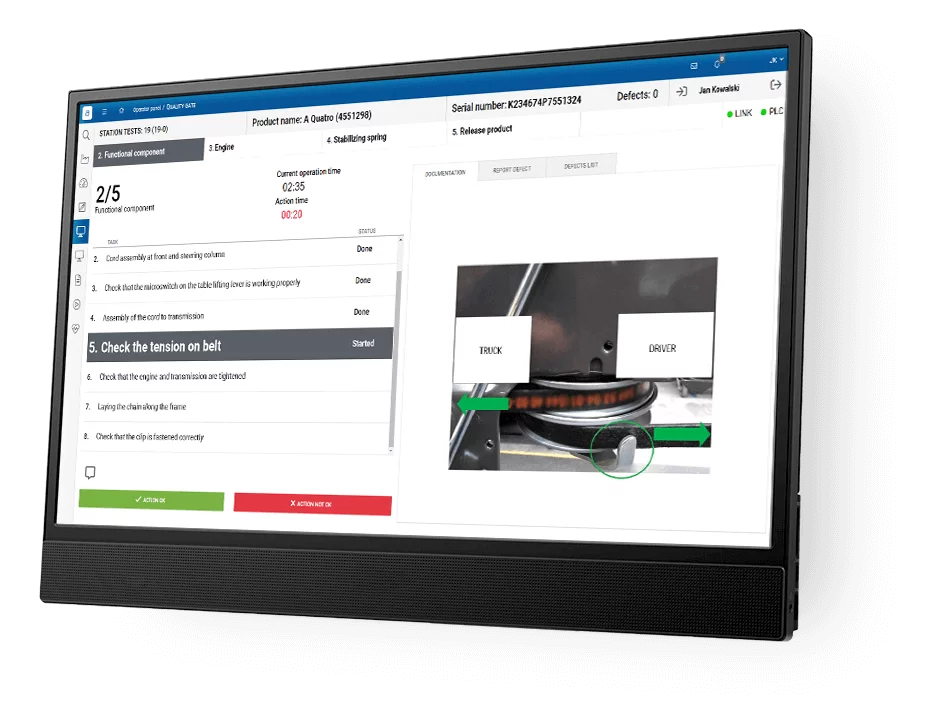

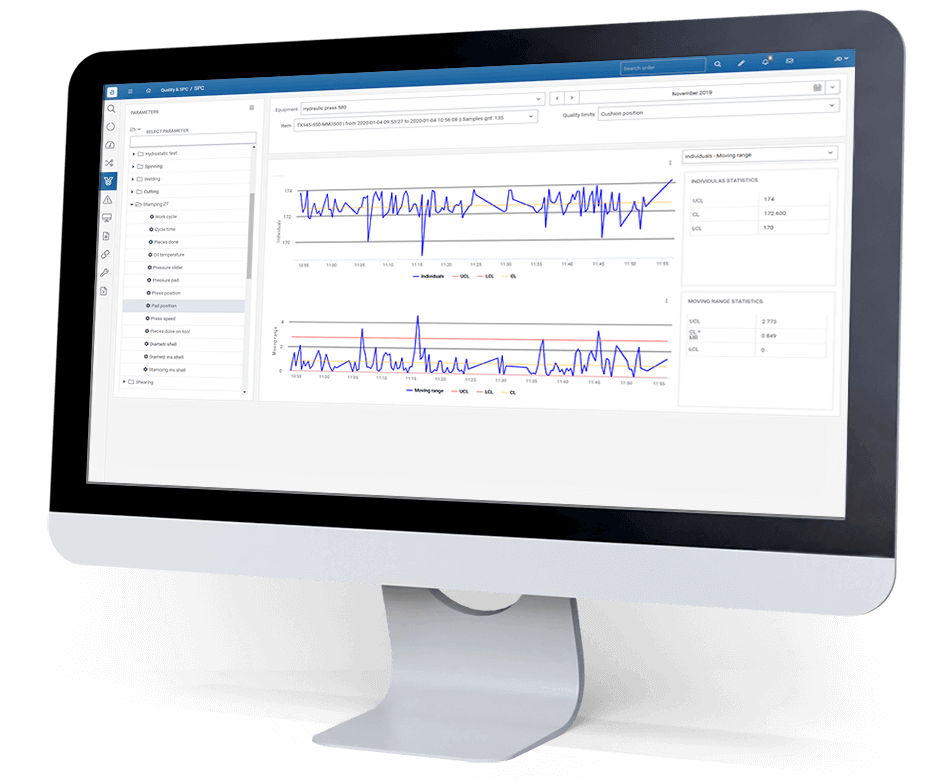

The quality module guides the operator through the inspection process and collects results in real time, allowing manufacturers to more quickly detect any non-conformities or problems in production and automatically generate SPC charts. Early detection of an unstable production process helps prevent costly errors and repair work.

An MES system can improve communication between departments, helping to ensure that information is exchanged and executed in a timely manner. By tracking production, we can be assured that each stage of the process is performed on time and to the required specifications.

We give you the numbers

Products for Manufacturing Industries

MES System – Manufacturing Execution System – ANT Solutions

System MES – Manufacturing Execution System 0 % operating time increase 0 % defects quantity reduction 0 % material consumption reduction 0 % changeovers time

Energy Management System (EMS)

Energy Management System (EMS) Monitor utilities usage in real-time and reduce cost Schedule a Demo They Trusted Us: What is ANT EMS? ANT Energy Management

Advanced Planning and Scheduling (APS)

AdvancedPlanning & Scheduling (APS) Planning and scheduling production is made more accessible with ANT’s APS software. Maintain a constant production pace with the help of

Operations we support

- aging

- assembly

- automated assembly

- automated welding

- bending

- CNC machining

- cutting

- dosing components

- drawing

- EOL test units

- extrusion

- final packaging

- flow forming

- injection

- labeling

- laser welding

- manual assembly

- manual welding

- marking

- milling

- montage

- packaging

- pressing

- printing

- programming electronics

- stranding

- test, quality & rework

- rooms

- thermoforming

- welding

- winding

Machines we support

- assembly

- stations/machines

- bending machine

- conveyors

- CNC

- injection machines

- inspection machines

- laser

- oven

- press

- pressure test machines

- punching machine

- quality control machines

- robots

- welding machines/

- welders

Product we produce

- carpet

- covering

- dish washers

- energy

- felt

- fiber

- foil

- household goods

- light bulbs

- metal components

- packages

- PCB boards

- plastic components

- refrigerator

- riders

- screens

- TV

- welding wire

System Presentation

Contact with our Expert

Why to get a demo?

- A 60-minute online meeting with a dedicated specialist presenting a top system from an industry similar to yours

- Live modeling of your production process

- A budget quotation after the meeting

Related Articles

How to automatically send recipes, setpoints and programs to machine and its PLC?

Production management and consistent pursuit of high quality of products – irrespective of the industrial sector or final goods – is closely linked to the

Why do MES and IT projects often go over budget?

Making the decision to implement a manufacturing execution system is just the tip of the iceberg. The next stage is to refine the details of

How to manage production by using modern shopfloor WMS and Autonomous Mobile Robots? (VIDEO)

Modern factories must constantly develop and raise efficiency indicators to achieve and maintain a strong market position. One of the ways to do this is