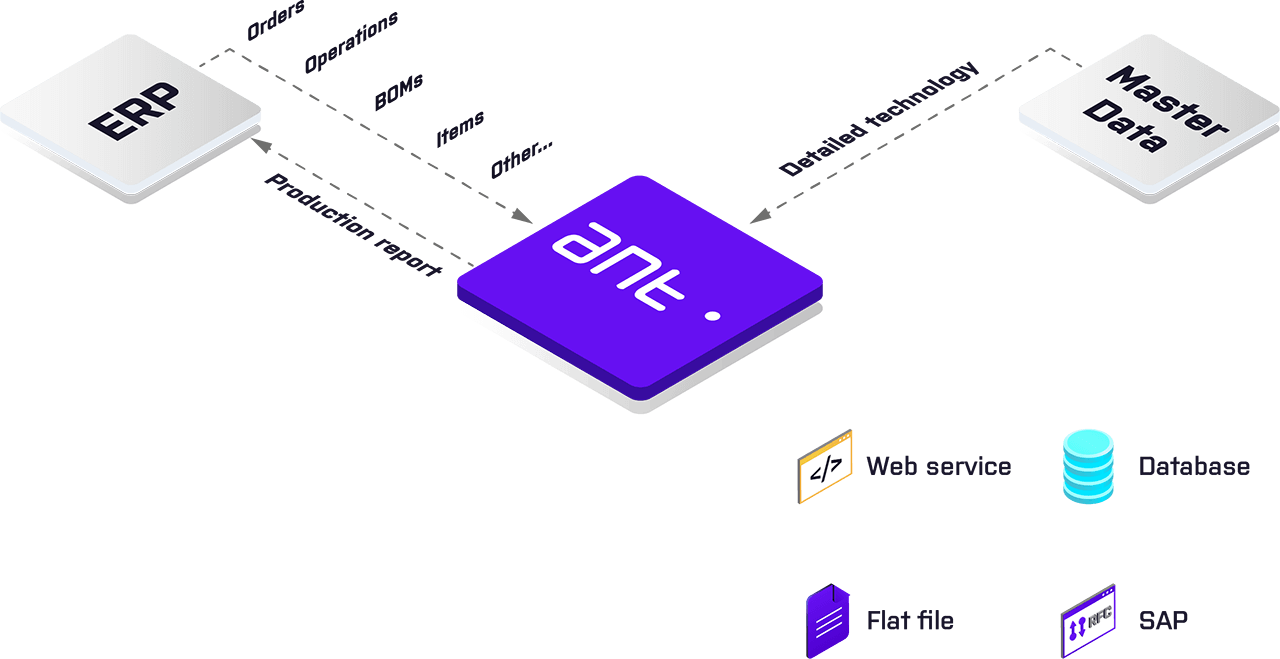

Production system Integration module is responsible for receiving inbound data from ERP and for sending outbound data to any other external system. It works in real-time to provide the most up-to-date information on your display and generate production reports. Comprehensive connectivity across the facility is a key factor influencing the seamless data flow and interoperability of internal and external systems. For the vast majority of implementations, ANT delivers the system along with the necessary ERP integrations to cover the core factory workflows.

Our manufacturing system integration empowers you to achieve:

- Real-time Production Data Access: Access real-time production data from your production system, enabling informed decision-making.

- Enhanced Manufacturing Efficiency: Streamline production processes, reduce errors, and improve overall efficiency.

- Improved Production Planning: Make data-driven decisions for better production planning and scheduling.

- Enhanced Workforce Management: Optimize workforce allocation and scheduling based on production demands.

- Increased Manufacturing Visibility: Gain comprehensive visibility into production operations, identifying potential bottlenecks and areas for improvement.

Key benefits

Inbound and Outbound Interface with external systems like ERP, WMS, APS, Cloud…)

Built-in import mechanism from auto generated and proper structured Excel files

Resend mechanism for production reports interface

How we integrate production process and create reports?

Time reduction and no need for dual production reporting thanks to automatic interface to ERP

Interface synchronization to keep the same data and managed only in one system

More agile and quicker way to manage production

Different integration ways are supported like:

- Web services: Utilize modern web services standards for secure and reliable data exchange.

- RFC: Leverage SAP's Remote Function Call (RFC) protocol for seamless integration with SAP ERP systems.

- Intermediate database: Employ an intermediate database to serve as a data exchange hub for heterogeneous systems.

- List Item

- Flat files (xml, csv): Utilize standard file formats (XML, CSV) for compatibility with legacy systems.

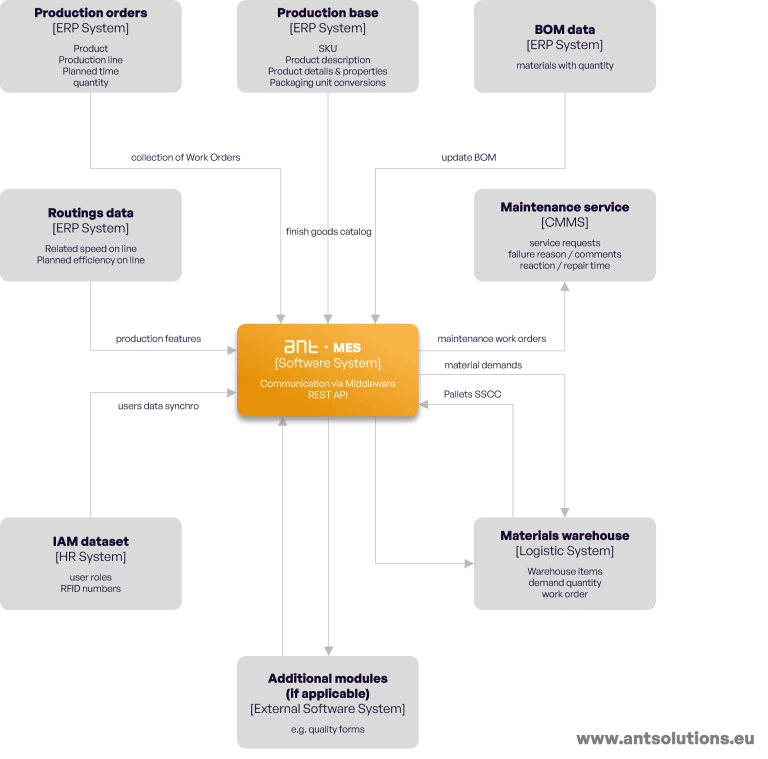

Integration with MES and CMMS

MES integration with ERP and CMMS systems are the most common we do. What usually do we connect?

Integration with MES

Inbound interface (from ERP to MES):

- Items (item code, type, group, unit, properties)

- Routing (operation code, operation name, equipment code, default tempo)

- BOM (BOM position, operation code, component code, unit, amount, conversion amount)

- Production orders with operations (order number, item code, version&revision of item, due date, operation number, equipment code, planned start date and time, estimated end date and time, amount, unit)

- Defects dictionary (defect code, defect name)

- Failures dictionary (failure code, failure name)

Outbound interface (from MES to ERP):

- Production report (production order number, operation code, equipment code, item code, good quantity, bad quantity, defect reason, operator ID, start timestamp, finish timestamp)

- General – each change in the data in ERP must be recorded in the interface with the timestamp

Integration with CMMS

Inbound interface (from CMMS to the MES):

- After whole process in CMMS system, closing the issue from CMMS triggers sending information to MES about finished maintenance work. From that moment, operator can start production order on MES system

- End of maintenance work (equipment code, status)

Outbound interface (from MES to CMMS):

- Information from MES to the CMMS that the failure has started – reported from ANT operator panel. The rest of the process will be handled in the CMMS system

- Failure report (failure start date and time, failure end date and time, reason for the failure, comment from operator, comment from technician, equipment code, status)

Related articles

How to make your meetings on the shopfloor more efficient?

Meetings on the shopfloor are pretty much an everyday occurrence and are essential to keep things running efficiently and effectively. The type and quantity of

How to effectively monitor production progress in real-time?

The tracking of changes in production – progress, lead times, possible sources of delays – plays a particularly important role in the industry. Delivering products

How to monitor and control automated assembly production line?

With the advent of Industry 4.0, broadly defined automation of production lines has become a standard, without which it is difficult to imagine a modern