Micro-stoppages, also known as small stops or short stops, are a common problem in the manufacturing industry. They refer to brief interruptions or delays that occur during the production process, which may only last for a few seconds but can add up over time, leading to significant losses in productivity and efficiency. In this article, we will explore the causes of micro-stoppages during the manufacturing process and provide some solutions to address them.

Causes of micro-stoppages during the manufacturing process

-

- Equipment malfunction: Equipment failure is one of the most common causes of micro-stoppages. It can occur due to a variety of reasons, including wear and tear, lack of maintenance, or improper use. Some examples of equipment malfunction include jammed sensors, misaligned parts, and faulty wiring.

-

- Operator error: Operators play a critical role in the manufacturing process, and even small mistakes can lead to micro-stoppages. These errors can be caused by a lack of training, fatigue, distraction, or simply human error. Examples of operator errors include forgetting to perform routine checks, misplacing tools, or improperly setting up equipment.

- Material handling issues: The way materials are handled can also contribute to micro-stoppages. This can include issues such as poor inventory management, improper storage, or incorrect labeling. Material handling issues can lead to delays in production, as well as increased downtime due to the need for corrective action.

- Environmental factors: Environmental factors such as temperature, humidity, and lighting can also impact the manufacturing process and lead to micro-stoppages. For example, if the temperature is too high or too low, it can cause equipment to malfunction, while poor lighting can lead to operator errors.

- Process inefficiencies: Process inefficiencies can arise due to a variety of reasons, including poor planning, lack of standardization, or inefficient workflows. These inefficiencies can lead to delays, rework, and increased downtime, all of which can contribute to micro-stoppages.

- Power Outages: Power outages can also cause micro-stoppages. If the manufacturing facility experiences a power outage, it can cause the production line to halt temporarily.

Solutions to address micro-stoppages during the manufacturing process

- Regular equipment maintenance: One way to address equipment malfunctions is to perform regular maintenance checks. This can help identify potential issues before they become major problems, reducing the likelihood of micro-stoppages.

- Proper training: Properly trained operators are less likely to make errors that lead to micro-stoppages. Providing regular training and refresher courses can help ensure that operators are equipped with the knowledge and skills they need to perform their jobs effectively.

- Improved material handling: Implementing better inventory management and material handling processes can help reduce the likelihood of material-related micro-stoppages. This includes properly labeling materials, ensuring that they are stored in the correct location, and establishing regular inventory checks.

- Environmental control: Maintaining a consistent environment in the manufacturing area can help reduce the likelihood of micro-stoppages caused by environmental factors. This includes controlling temperature, humidity, and lighting levels to ensure optimal conditions for both equipment and operators.

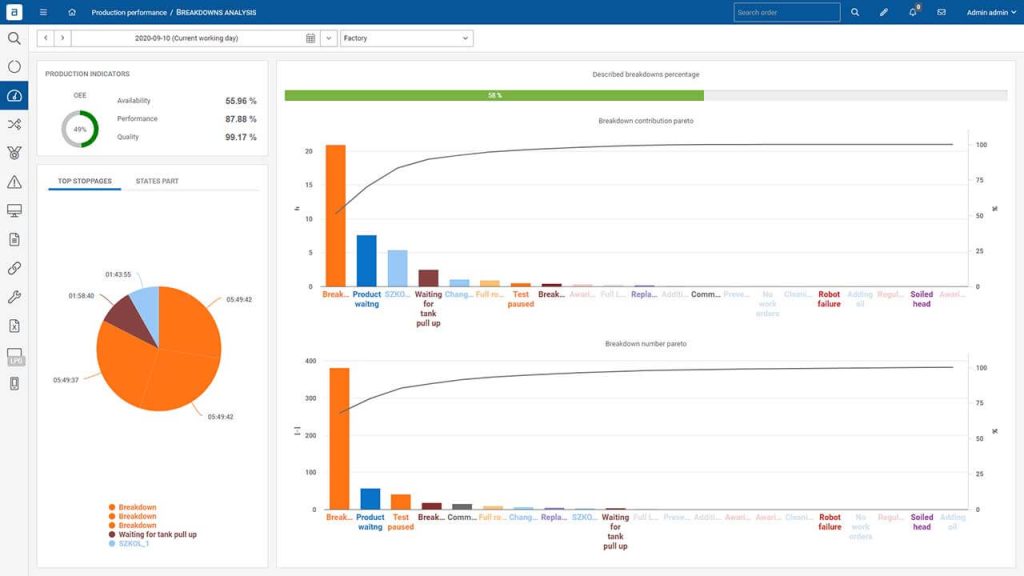

- Process optimisation: Optimising manufacturing processes can help reduce inefficiencies that contribute to micro-stoppages. This includes identifying bottlenecks and areas where processes can be streamlined or standardized to improve efficiency and reduce downtime. You can use Microstops Monitoring solution by ANT to monitor every stop and find the root cause on the Pareto chart.

FAQs:

Q: How do micro-stoppages impact productivity?

A: Micro-stoppages can add up over time, leading to significant losses in productivity and efficiency. While each individual stoppage may only last for a few seconds, over time, they can result in significant amounts of downtime, which can impact production schedules and ultimately result in missed deadlines

Q: What is a micro-stoppage?

A: A micro-stoppage is a brief halt in production that can cause delays and impact productivity.

Q: What causes micro-stoppages?

A: Micro-stoppages can be caused by equipment failure, poor maintenance practices, operator error, material shortages, process design, environmental factors, and power outages.

Q: How can micro-stoppages be prevented?

A: Micro-stoppages can be prevented through regular maintenance, proper operator training, material planning, proper process design, environmental control, and backup power sources.

Products in this Article

ANT Microstops (production monitoring, performance) system on SMD (FMC), FMD, THP, and OTP in Tobacco factory

The factory was in a phase of digital transformation, which included digitalization, working methodology, and IWS ready methodology. Tobacco production is characterized as a high-speed

Microstops monitoring

MIcro stopsmonitoring The most effective system for FMCG for monitoring production rates and downtime Schedule a Demo What are micro stops and why are so

OEE Performance monitoring

Performance Monitoring (OEE) Connect and gather data from your machines. Schedule a Demo They Trusted Us: Key Benefits OEEincrease ✔️ shorter downtimes ✔️ faster production