How defect handling works?

Defect Handling module supports defect and scrap management. Operators can report defects and its type with an easy touch screen interface. At any given moment, module may display a dedicated report with defects reasons and quantity. Defect Handling module is a part of Operation Panel which displays production progress counters in real-time.

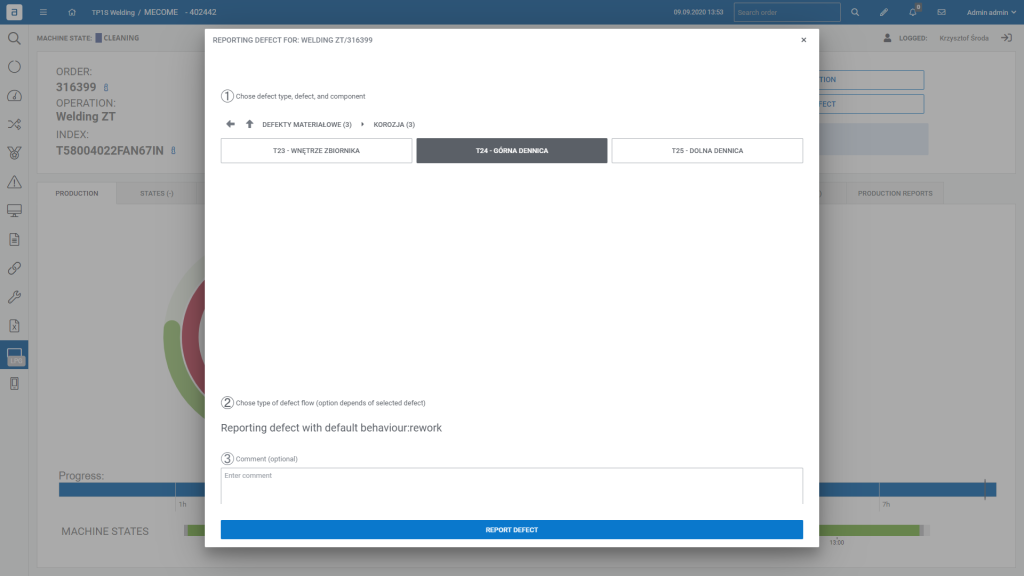

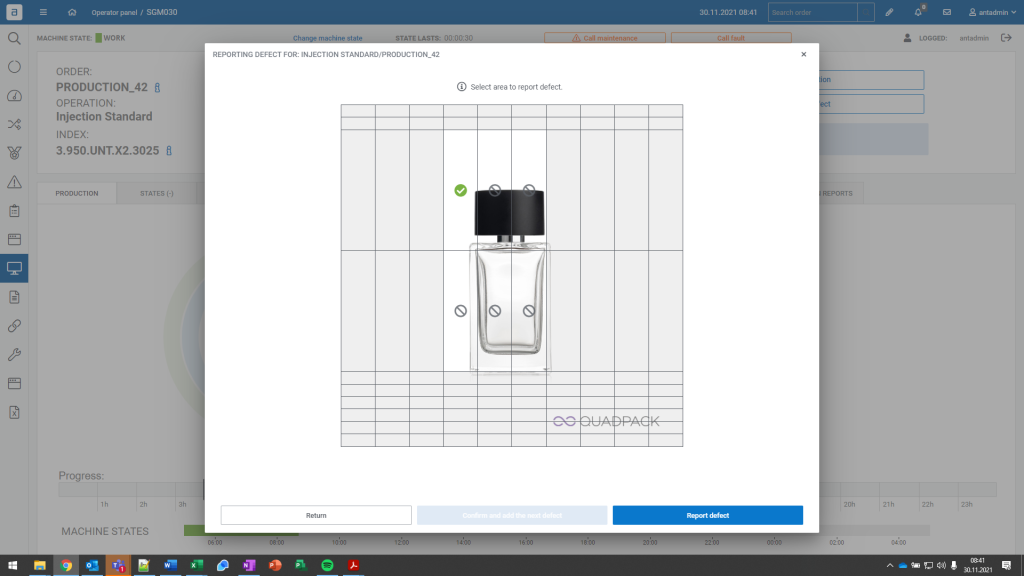

To ensure quality control, the administrator can use flexible system policies to configure rules to prompt the operator to start defect detection after “x” units are produced and/or “y” minutes. The operator is guided by documentation (PDF, photos, videos) through the detection process and can report defects using a dictionary. The system helps decide if the produced piece is scrap or can be sent for rework. The administrator can also define rules for when to escalate defects (e.g.. 3 defects within 5 minutes; quality less than 98%, etc.).

Modiles is equipped with an extensive modelling function which allows the user to configure fields for defects: name, code or category. The system lets user assign defects to items, item groups or operation types.

How to reduce defects?

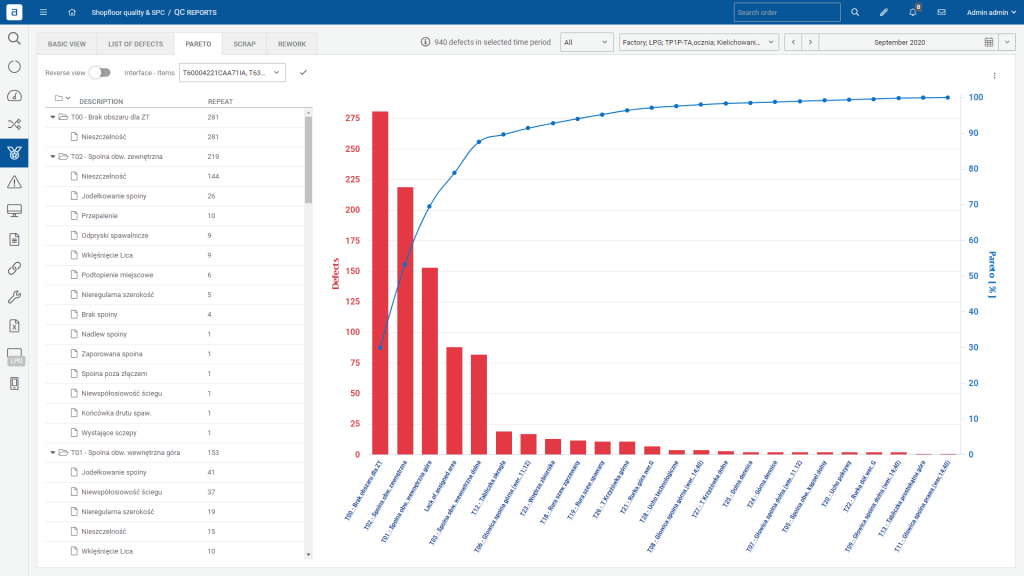

Use built-in tools to analyze the most defective machine or item. The system automatically reports defects with reason if data is available from PLC. Display Pareto charts and analyze historical data to find areas to improve. Use the real-time notification to inform about defects in the escalation path.

On top of automatic analysis, the operator is able to report defects manually by choosing its defect type.

Savings

Customer managed to generate 13% savings by early escalation of too many defects

Less waste

Customer have reduced the waste of the raw material by 15%

How defect handling module improves lean manufacturing?

Reducing the number of defects is one of the key goals of lean manufacturing. The system provides user with high-quality information which can be used to make improvements. For instance, quality-checking raw materials to guarantee that they do not make defective goods, or simply doing equipment maintenance to ensure that they do not malfunction and produce poor products, can lead to meeting lean manufacturing goals.

User can manage defected components by assigning them to the defect code and areas so the operator can additionally describe visually where the defect has happened on the item.

Manage defect reasons and assign them to the defect so the operator can point out what was the source of the found defect (i.e. other machine or operation)

Read an article:

How to optimize production plan?

Nowadays, production planning requires particular precision, operating in real time and updating objectives in relation to the current state of the machines.