Computerized Maintenance Management System (CMMS)

Plan, manage and react with CMMS System by ANT. The best maintenance system for equipment performance in your factory. It allows to schedule repairs and maintenance based on actual machine cycle time. Increase machine availability and reduce downtime to increase plant productivity.

What is a CMMS system and how does it work?

Computerised Maintenance Management System (CMMS System) is a software that allows controlling the costs of the Maintenance department, spare parts levels and plan labor works. The CMMS supports the supervision of plant maintenance and the planning of maintenance work, as well as enabling preventive and ad-hoc activities. The collection of data and observation of events on the operation of machinery in real-time makes it possible to precisely determine the timing of subsequent inspections and maintenance work.

Integration of the CMMS system with other IT systems such as APS makes information about machine failure and the need to reschedule production processes reach users instantly. Maintenance activities in the plant are thus organised and carefully planned, and regular attention to the proper condition of machines allows minimising the overall number of repairs.

CMMS System - Who is it for?

A CMMS system is for all companies that want to optimise their maintenance processes in their plants. This includes manufacturing companies from various industries, such as FMCG, automotive, military, pharmaceutical and others.

A CMMS system can help companies improve their machine fleet maintenance processes in a number of ways, including:

- Tracking assets and maintenance tasks

- Generating digital reports on maintenance costs and performance

- Prioritising maintenance tasks

- Automating maintenance tasks allowing for preventive maintenance process

- Paperless documentation flow in the facility for the entire plant maintenance

- Integrating with other systems, such as ERP and MES systems

Key functionalities of ANT CMMS system:

Automatic planning of cyclical events based on man-hours, man-cycles, time and machines work time

Maintain orders and requests management

Be up to date with daily schedule and get notifications for preventive maintenance

Paperless and forms for maintenance with multiple dashboards reports ready in the system

Maintenance ANDON

Access to the current tool consumption, status, types, properties and operations.

Employees skills and scheduler manager

Dashboards & Reports is a complex analytic platform with ready reports. More than dozen KPIs to analyze maintenance efficiency (MTBF, MTTR, MTTF), costs, trends and targets.

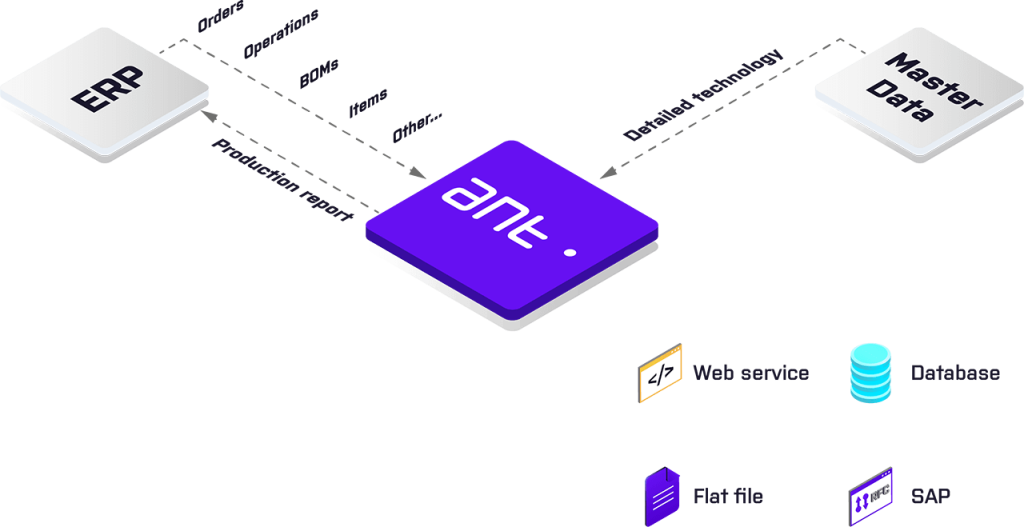

Can CMMS system be integrated with the rest of the factory?

CMMS seamlessly connects with various factory systems, including:

- Enterprise Resource Planning (ERP)

- Shop Floor Warehouse Management System (Shop Floor WMS)

- Automated Production Systems (APS)

- Manufacturing Execution System (MES)

Benefits of Integration are serval including:

- Real-time Information Sharing: Information regarding manufacturing processes, warehouse operations, and machinery maintenance can be shared paperlessly in real-time.

- Inventory Management: The CMMS system helps keep inventory records up-to-date and ensures spare parts availability for maintenance.

- Production Scheduling: Integration enables swift adjustments to production schedules in response to changes in machinery status or component availability.

- Accurate Forecasts: It facilitates the development of more accurate production forecasts.

Automated Procurement: Integration can support automated procurement processes, reducing stockouts and downtime. - Condition-Based Maintenance: Integration and machine connectivity enable the implementation of condition-based maintenance strategies to prolong equipment lifespan.

What are the benefits of using ANT CMMS SOLUTION?

Implementing a CMMS in a manufacturing plant is an effective way to automate maintenance tasks. Due to machine connectivity and preventive maintenance tasks, plant maintenance team can strengthened control over the machines fleet, precisely schedule maintenance work and quickly response to breakdowns, increase machine availability and reduce downtime, thus increasing productivity.

Work orders

Prevent breakdowns and ensure the proper condition of key machine components. Perform preventive maintenance to ensure safe operation of equipment.

- Precise scheduling of inspections and repairs based on real machines cycle times and operators work time

- Reminders for scheduled work, perform inspections in a timely manner

- Guarantee safe operation of machines in accordance with applicable standards such as ISA-95

Real-time monitoring of machine conditions

Make sound decisions based on real machine cycle data, thanks to machine connectivity. React instantly to changes related to their condition.

- Report failures quickly with paperless maintenance system

- Better control of repair times, reduce costs associated with repairs of major faults

- Increase machine availability and performance indicators

Control over a single machine and the entire machine fleet

Take advantage of the information provided by each machine. Comprehensive data will increase the level of control over the condition of all machines, tools and parts.

- Precise calculation of performance indicators

- Confidence in the proper operation of key tools

- Prevention of the occurrence of failures

Collect historical data

Use data collected over time to identify and eliminate bottlenecks. Closely monitor the elements that cause frequent failures.

- Instant access to a historical list of failures

- Ability to find and eliminate bottlenecks

- Track fleet maintenance costs

Tools, spare parts and warehouse management

CMMS programme allows you to optimise warehouse management by providing real-time information on tool availability and location. The system allows to set of minimum stock levels for spare parts or types of spare parts and will trigger a notification on reaching the minimum levels. The following filters for spare parts are available: reached minimum level, a discrepancy in quantity, reserved more than In the stock. The spare parts are added during the maintenance works and are summarised in the costs.

- Asset and equipment management, identify trends and make informed decisions about tool investments.

- Tools and calibrations helps to better manage the equipment by setting alarms on usage levels or periodic work orders

- Tool Room Management, real-time visibility into tool availability, location, and condition, ensuring that the right tools are readily accessible when needed

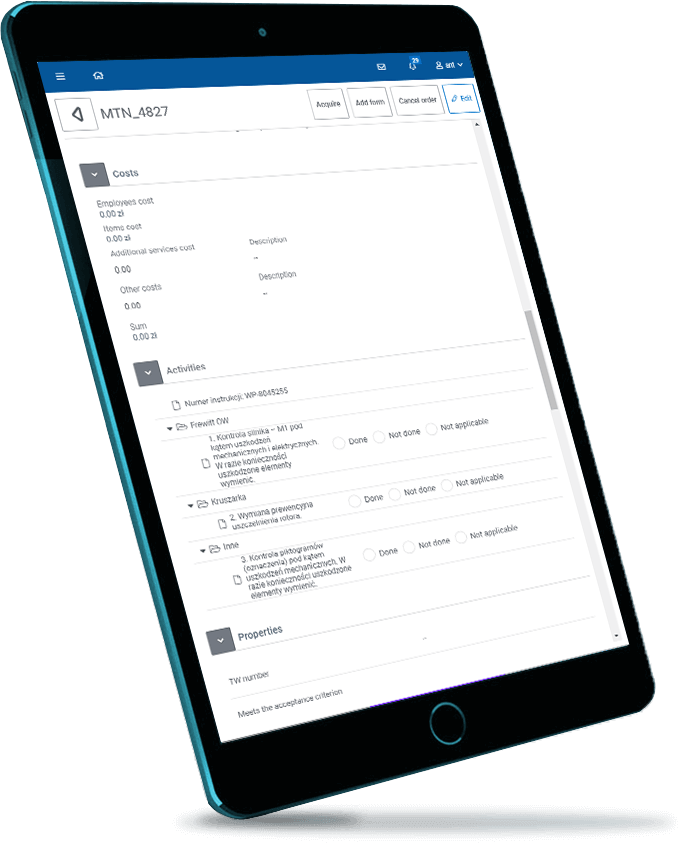

Paperless & Forms

During the work order, technicians fill Factory Forms thanks to the Paperless functionality.

The system is responsible for the digital guidance of the operator – starting from displaying activities (list to-do) with dedicated documentation (image, document, movie) for each step of the repair.

Workflow module (BPM) lets users create the business process workflow, events and gateways with custom logic.

Leave your email to get an offer

Data always up to date

The key factor for successful plant operation is knowledge of when inspections must be made. ANT machine connectivity expertise gives the possibility to schedule maintenance according to the actual working time of the machine. We put our effort into collecting true and up-to-date data, to deliver the most accurate information for the maintenance team.

The failure rate of machines can be calculated using mean time between failures (MTBF) and mean time to repair (MTTR). MTBF is the average time a machine runs before it fails. MTTR is the average time to repair and restart the machine.

The higher the MTBF, the lower the failure rate. The higher the MTTR, the lower the MTBF.

Failure rates are usually expressed as a percentage of total operating hours or total number of failures per 100 operating hours.

MTBF stands for mean time between failures. It is a measure of the average operating time of a machine or system before a failure occurs.

MTBF measures the reliability of equipment and is calculated by dividing the total operating time by the number of failures. MTBF is an important measure in reliability engineering because it can be used to predict when a machine will fail, allowing preventive maintenance to be performed before it fails.

CMMS System - How much can your factory benefit?

according to our clients, we helped them to:

Take care of the condition of your machinery fleet with ANT's CMMS!

At ANT, we are in the business of providing modern technological solutions used in the manufacturing industry, among others. CMMS is a proven software system that allows you to exercise better control over the technical condition of your machinery park. Our own source code and supervision of qualified experts allows us to us to offer a dedicated system tailored to the individual needs of each company.

Our customers confirm that after the implementation of CMMS ANT in their plants, the number of downtimes has significantly decreased, as well as the overall number of repairs. The result is an increase in the efficiency of production processes and better utilization of available machinery. Your plant can join this group too! Contact us for more information on implementing a CMMS at your company.

System Presentation

Contact with our Expert

Why to get a demo?

- A 60-minute online meeting with a dedicated specialist presenting a top system from an industry similar to yours

- Live modeling of your production process

- A budget quotation after the meeting

Related articles

How to guide operator on shop floor – step by step production and changeovers

Operator guidance is an essential part of the production process. It primarily ensures that the process is executed following the developed technological guidelines. Step-by-step support

How to measure maintenance times? (reaction, repair)

Full availability of the machinery park, control over downtime and maintenance lead times in the event of technical problems – these elements are among the