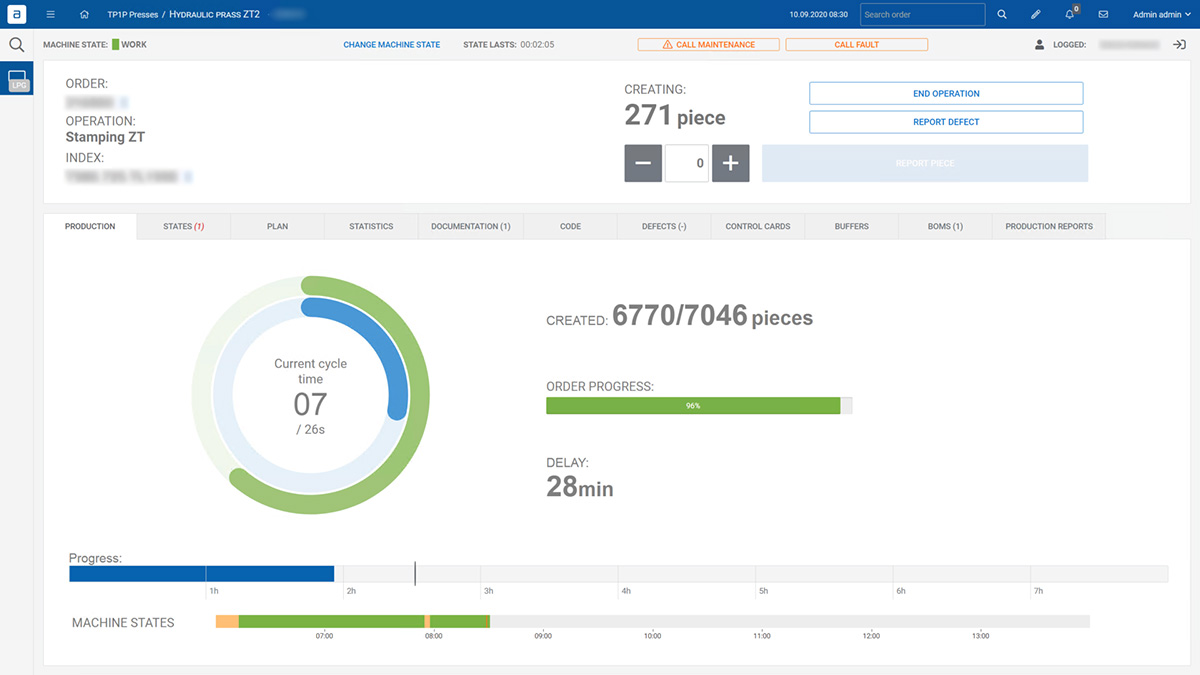

The Production Execution module lets operators execute orders and operations according to plan and technology. It validates and supports different types of production processes during which the operator can report production and machine states. The system displays current production, its status and progress.

Key functions

Starting production in a planned sequence

Display progress, main KPIs and current delay for ongoing production

Manual or automatic production reporting with machine states

How to report production?

After arriving at the workstation and logging in on the panel, the operator selects a production order that has been planned by the planner. All the actions he should perform to start production are displayed. Based on machine cycles or operator input system counts OK/NOK production. The system monitors machine states, which order is produced, its progress, and delays. Management can check the production health at a glance.

Key benefits

Faster and automated production launch with reporting

Automated validations and production counters

Machine states monitoring for further analysis

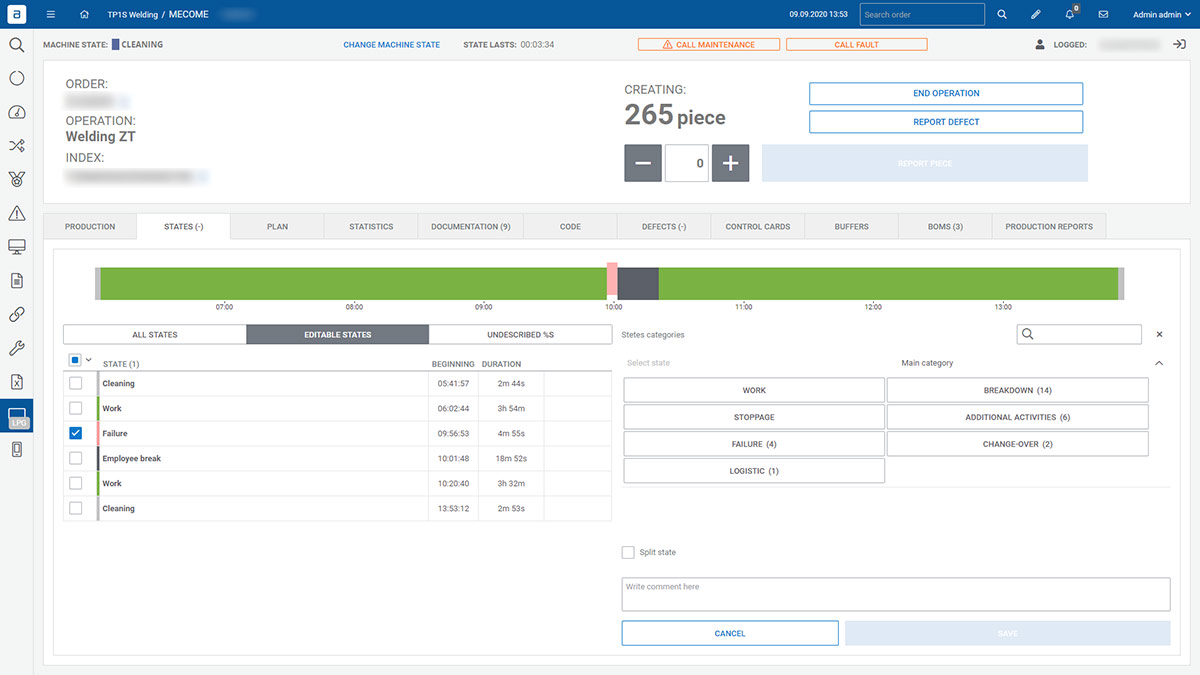

How to report production downtime?

Use a built-in dictionary of the machine states. The ANT system compares ideal cycle time with current results. When a production delay occurs, the system retrieves data from the PLC on the cause of the downtime or asked the operator to point it out. The administrator decides when the micro-stop is changing to downtime. Once the reason for the stop has been identified (failure, quality issue, lack of materials, etc.), the services concerned will be asked to react.

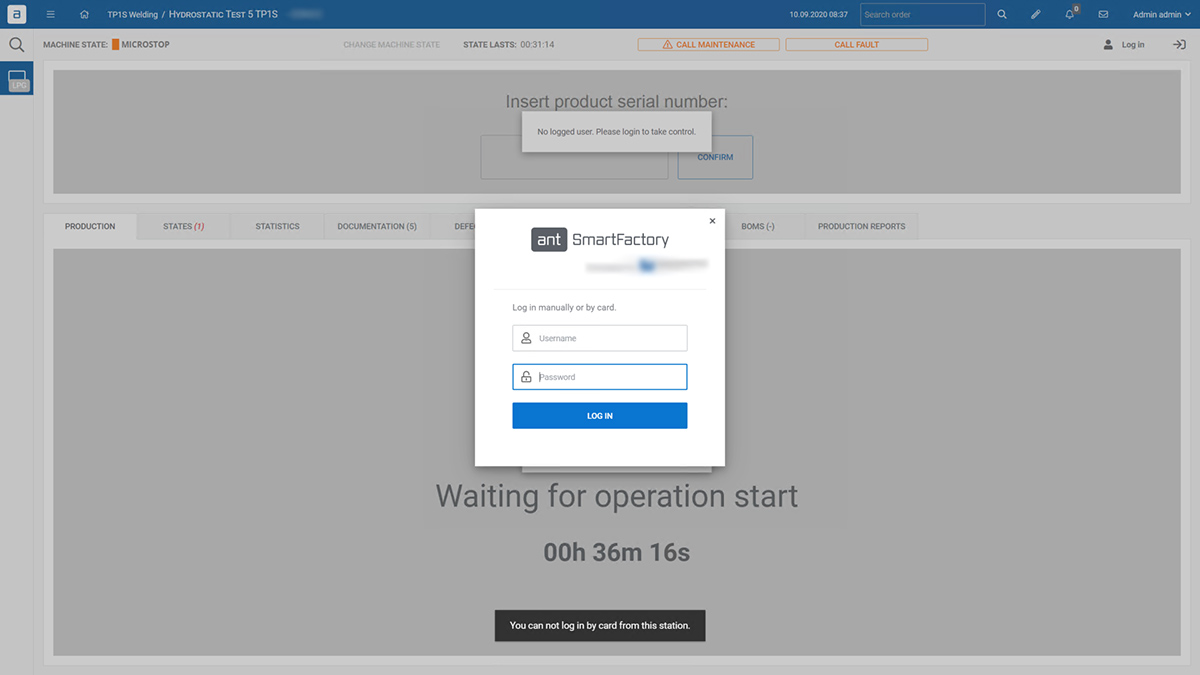

Users are be able to log into the system by manually providing username and password, using RFID card/tag, scanning 1D/2D code, or by using an NFC tag