Mit dem Modul Production Execution können Bediener Aufträge und Vorgänge nach Plan und Technologie ausführen. Es validiert und unterstützt verschiedene Arten von Produktionsprozessen, bei denen der Bediener Produktions- und Maschinenzustände melden kann. Das System zeigt die aktuelle Produktion, ihren Status und den Fortschritt an.

Wichtige Funktionen

Start der Produktion in einer geplanten Reihenfolge

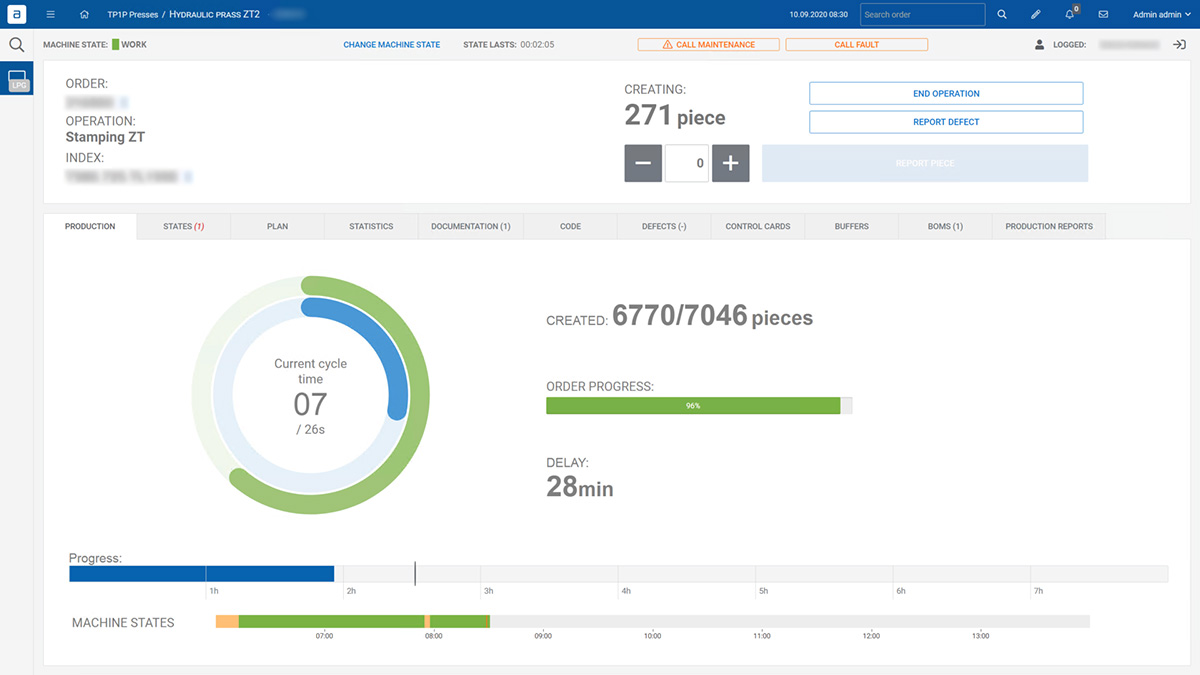

Anzeige des Fortschritts, der wichtigsten KPIs und der aktuellen Verzögerung für die laufende Produktion

Manuelle oder automatische Produktionsmeldung mit Maschinenzuständen

Wie wird die Produktion gemeldet?

Nach der Ankunft am Arbeitsplatz und der Anmeldung am Bedienfeld wählt der Bediener einen Produktionsauftrag aus, der vom Planer geplant wurde. Alle Aktionen, die er durchführen muss, um die Produktion zu starten, werden angezeigt. Auf der Grundlage von Maschinenzyklen oder Bedienereingaben zählt das System die OK/NOK-Produktion. Das System überwacht den Maschinenzustand, den zu produzierenden Auftrag, seinen Fortschritt und Verzögerungen. Das Management kann den Zustand der Produktion auf einen Blick überprüfen.

Wichtigste Vorteile

Schnellerer und automatisierter Produktionsstart mit Berichterstattung

Automatisierte Validierungen und Produktionszähler

Überwachung der Maschinenzustände für weitere Analysen

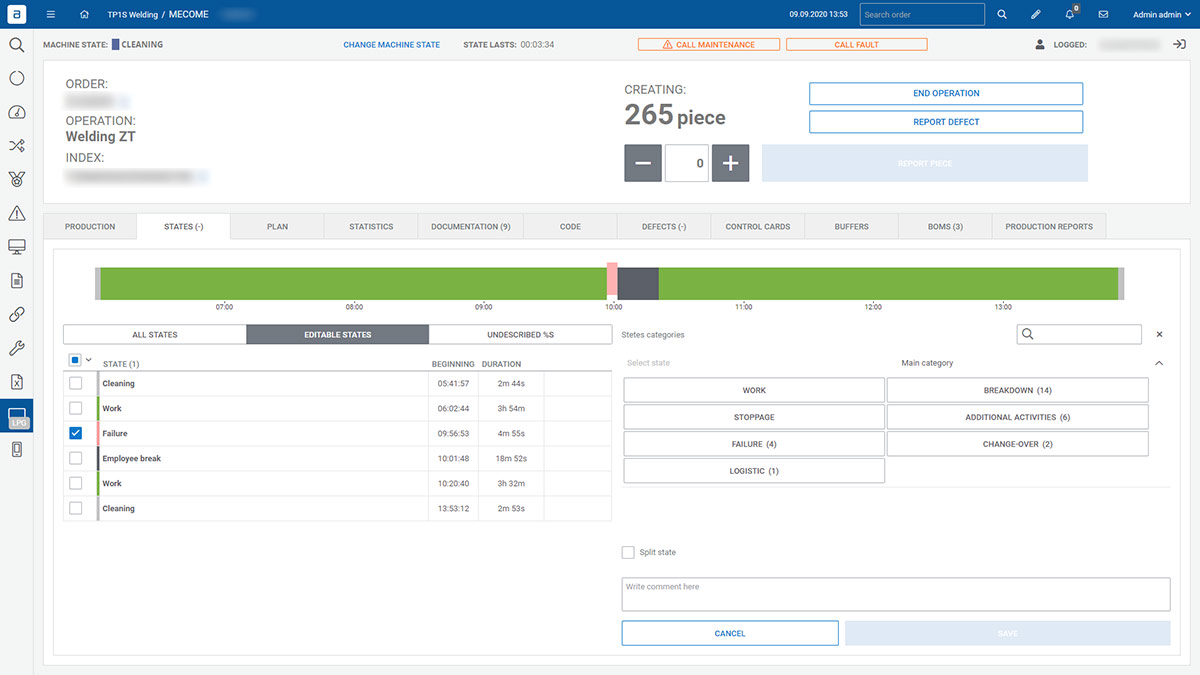

Wie meldet man Produktionsausfallzeiten?

Verwenden Sie ein eingebautes Wörterbuch der Maschinenzustände. Das ANT-System vergleicht die ideale Zykluszeit mit den aktuellen Ergebnissen. Wenn eine Produktionsverzögerung auftritt, ruft das System Daten von der SPS über die Ursache des Stillstands ab oder bittet den Bediener, ihn darauf hinzuweisen. Der Administrator entscheidet, wann der Mikrostopp in einen Stillstand übergeht. Sobald der Grund für den Stillstand ermittelt wurde (Störung, Qualitätsproblem, Materialmangel usw.), werden die betroffenen Dienste aufgefordert, zu reagieren.

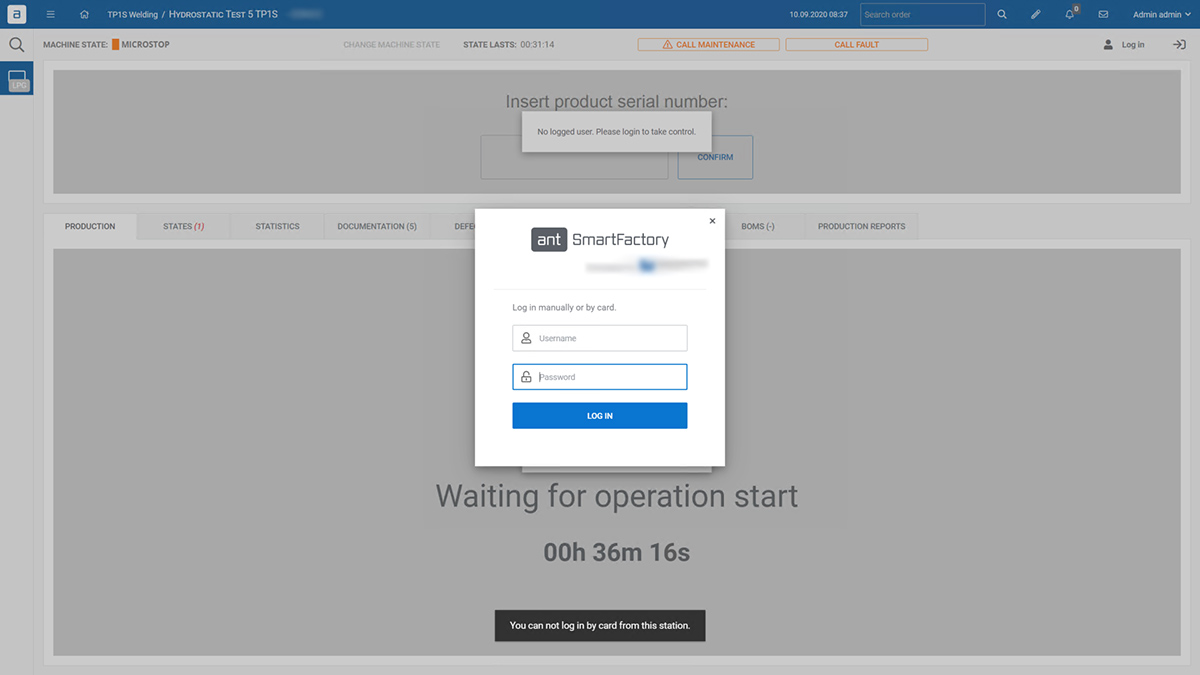

Die Benutzer können sich am System anmelden, indem sie manuell einen Benutzernamen und ein Passwort eingeben, eine RFID-Karte/einen RFID-Tag verwenden, einen 1D/2D-Code scannen oder einen NFC-Tag verwenden.