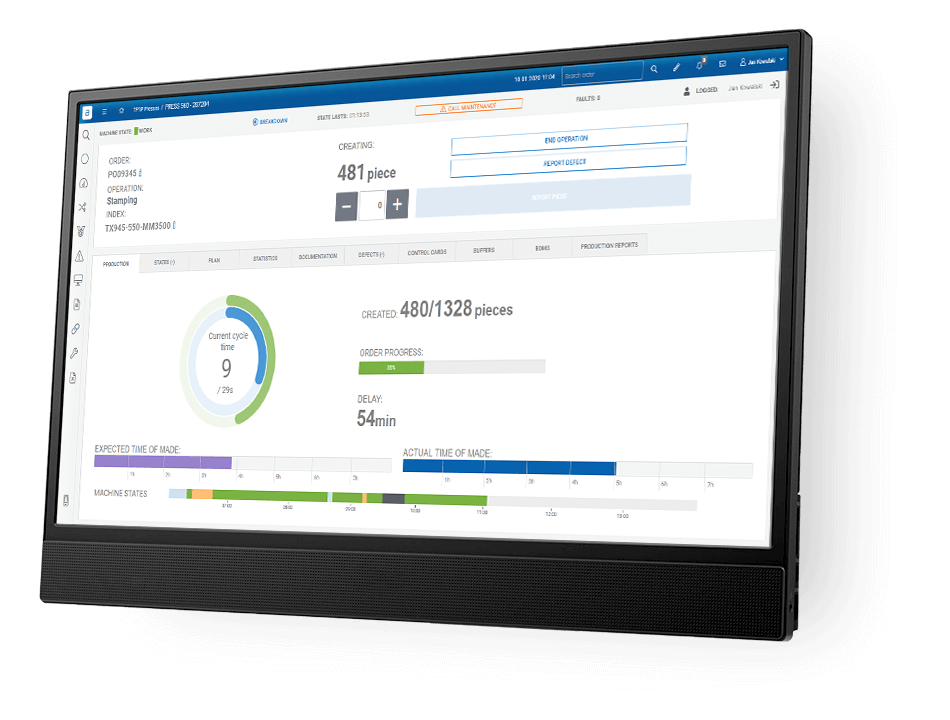

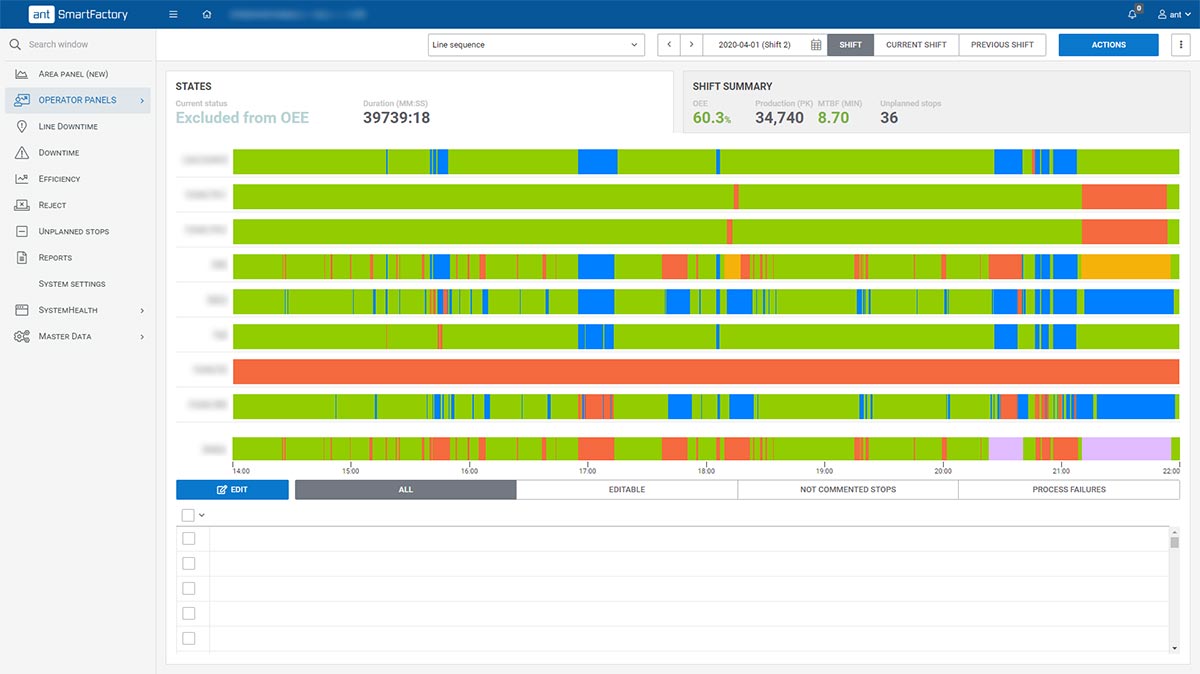

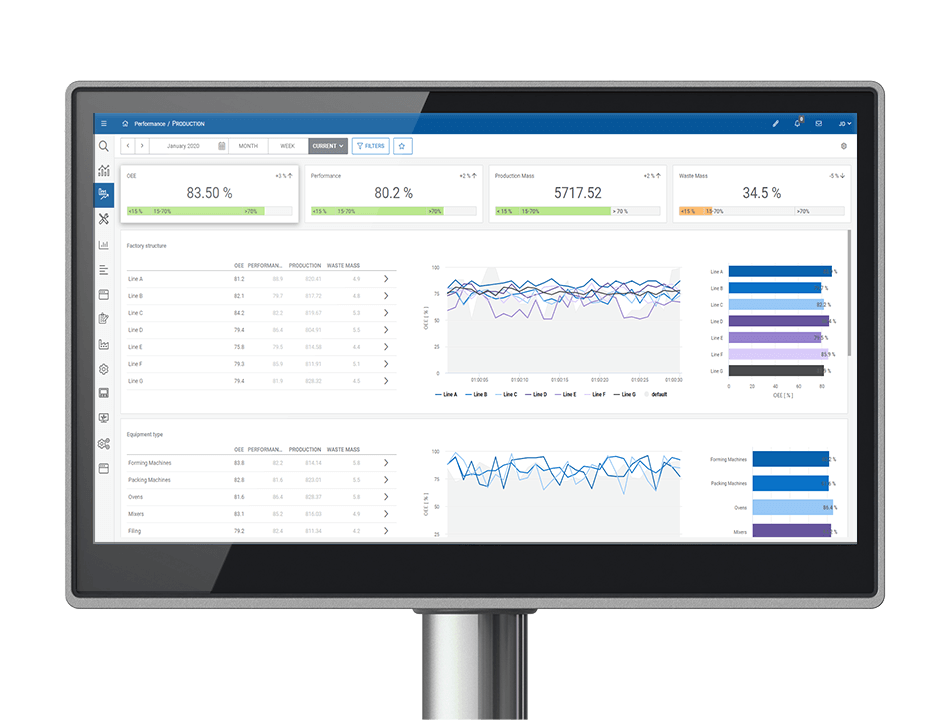

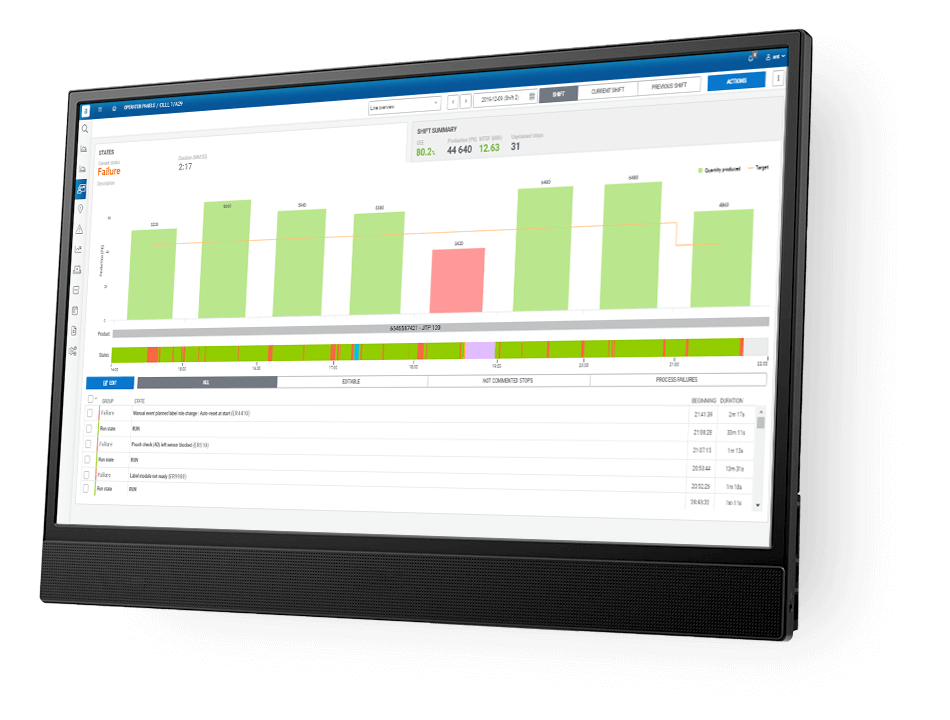

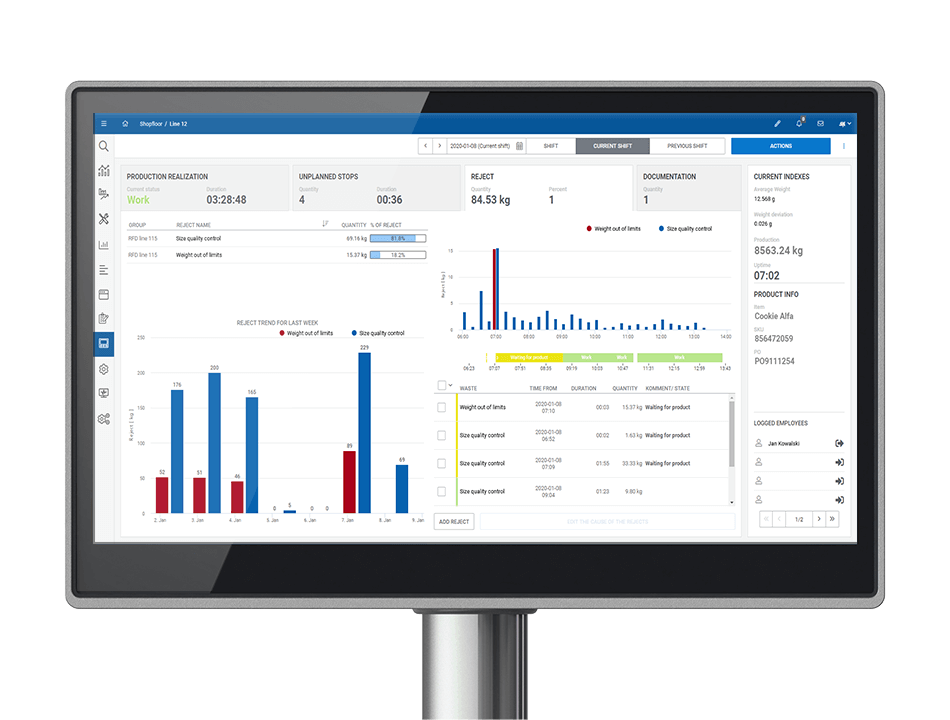

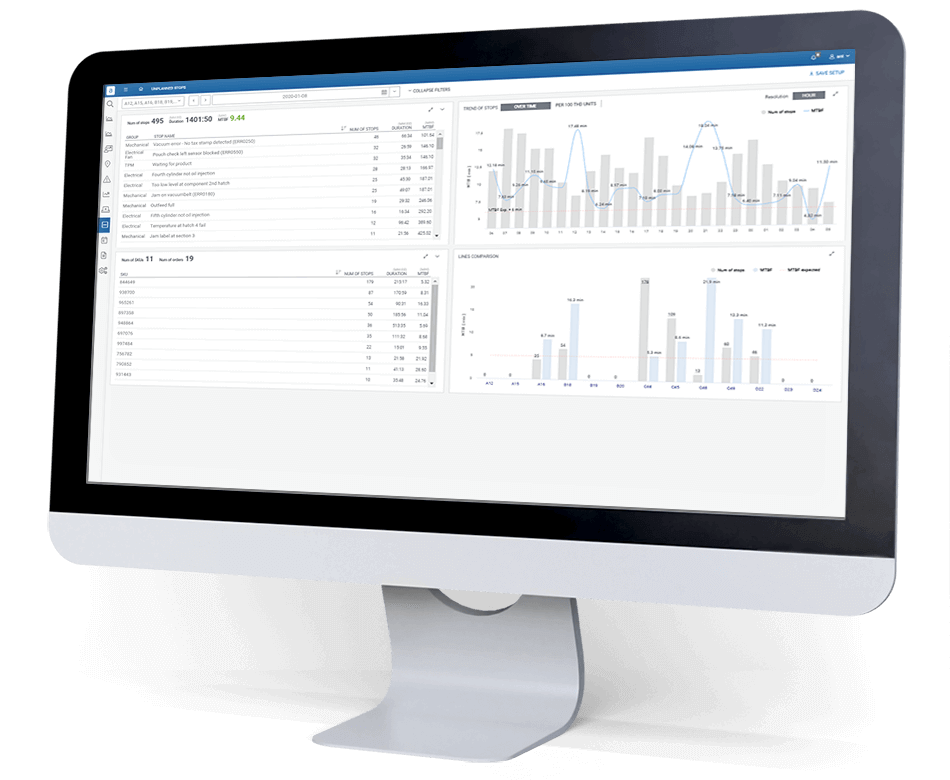

ANT Microstops (production monitoring, performance) system on SMD (FMC), FMD, THP, and OTP in Tobacco factory

The factory was in a phase of digital transformation, which included digitalization, working methodology, and IWS ready methodology. Tobacco production is characterized as a high-speed