The process of creating incremental changes to products, services, processes, or systems is known as continuous improvement. It is a continuous attempt to improve product and service quality, increase efficiency, and minimize costs. Continuous improvement seeks to discover and improve existing methods and procedures in order to maintain a high degree of quality and consistency.

Continuous improvement applies to all sectors of company and entails a combination of research, analysis, experimentation, and change implementation. It is a continuous process of aiming for perfection while keeping consumer input and market conditions in mind. Continuous improvement can result in better customer happiness, less waste and errors, and increased revenues.

Learn how microstops monitoring, paperless production, interactive meetings or machine control module can boost your productivity, increase production volumes and meet compliance standards.

Working in production requires continuous improvement of processes and more efficient tools that help in daily activities. At ANT, we understand these needs, which is why we respond to them with additional modules that supplement missing features in the production line.

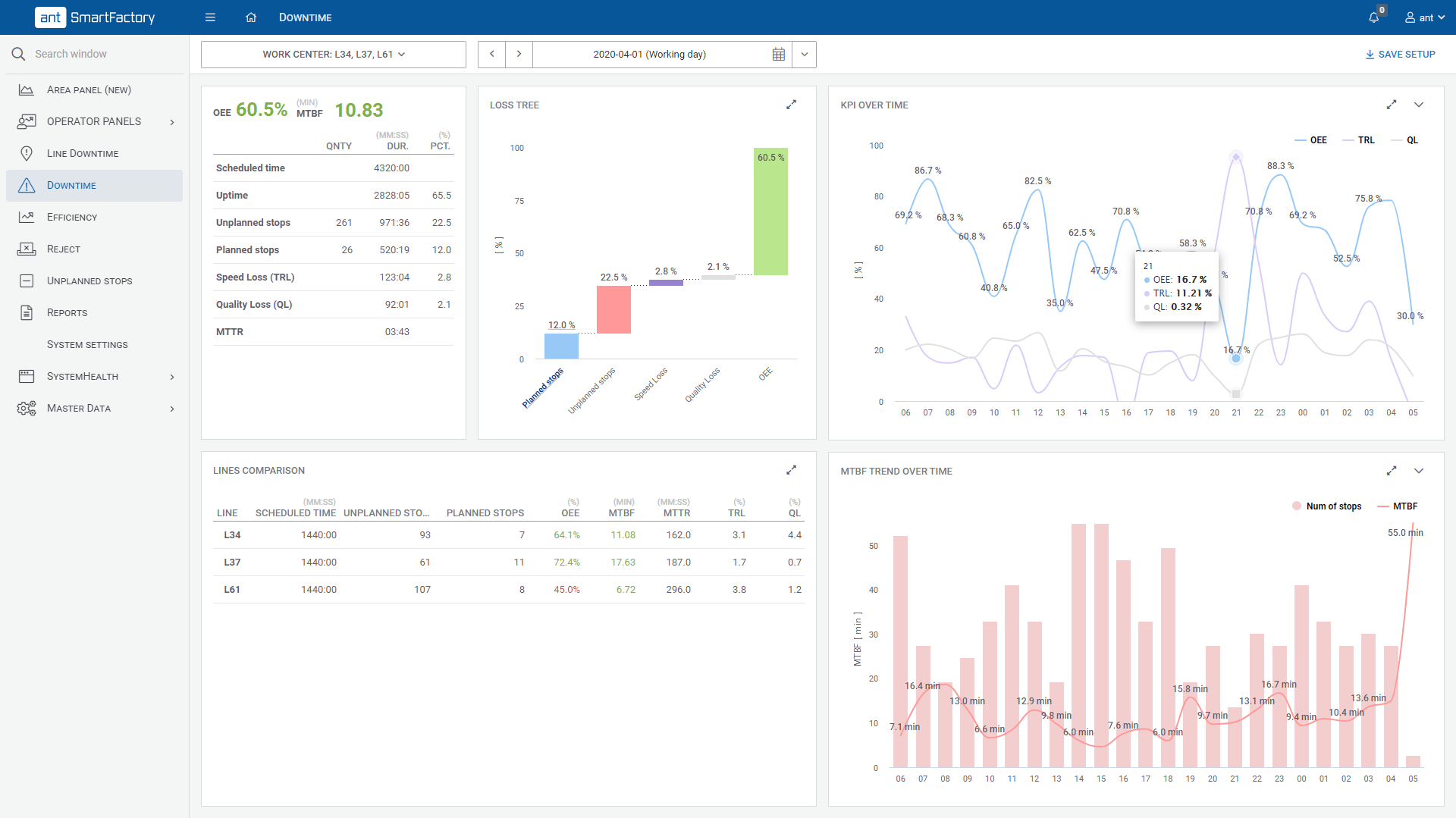

Detect automatically each, even the shortest stop of the machine with its reason from PLC

Do the deep integration with PLC to get even thousands of alarms and production data

The algorithm calculates the responsible machine and its root cause for line stop

Get accurate, aggregated, real data to stop the stops

Understand why the machines lose availability and have actual data to take actions

Spend less time for manually reporting machine states

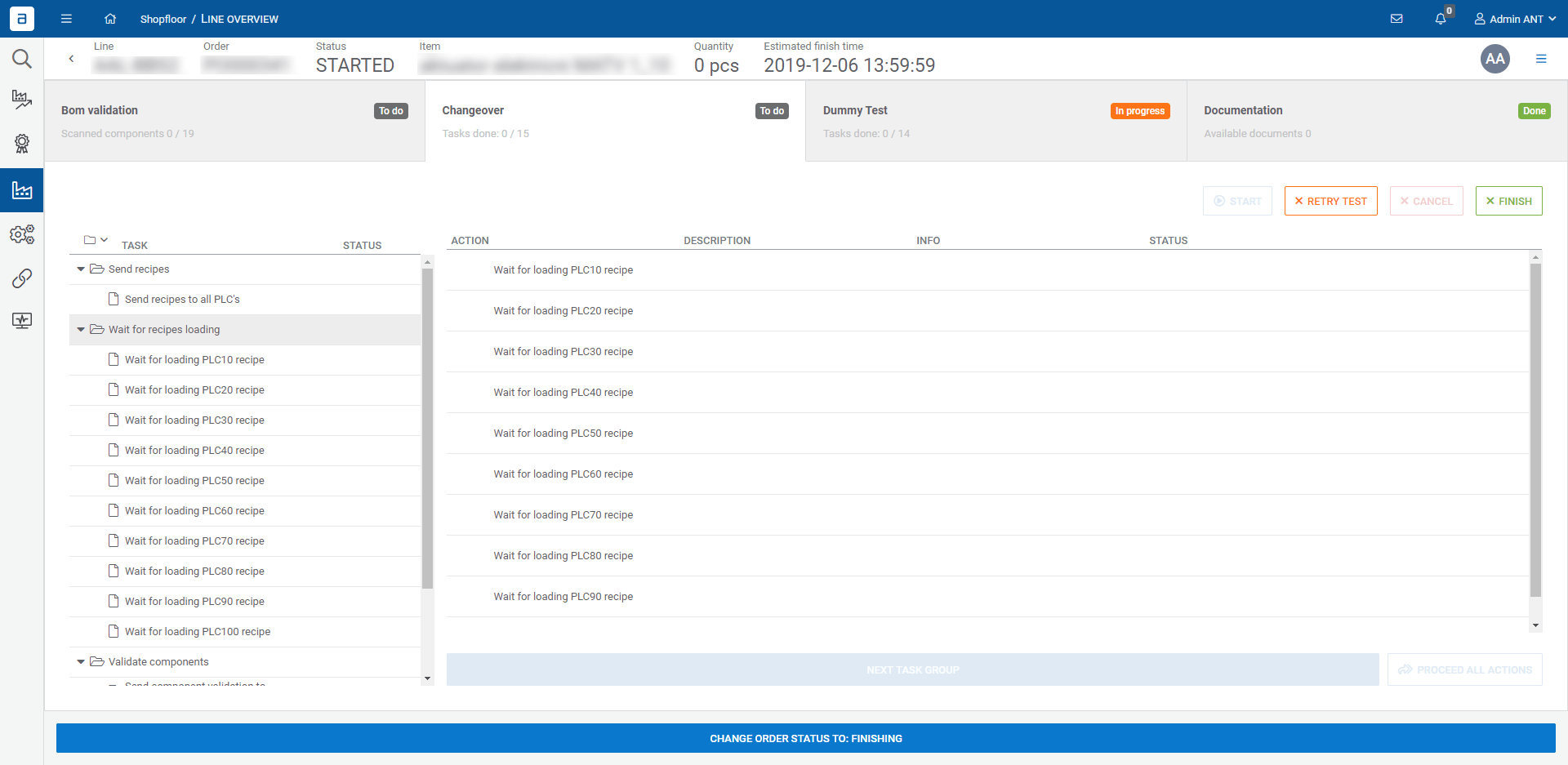

Replace all paper documents, forms, instructions with the digital version by using the drag&drop tool

Display step by step activities to guide the operator through production and changeover

Fill the data automatically in the forms based on data from machines and production order

Save time and money thanks to paper and paperwork elimination

Ensure that the production process was executed with planned, standardised technology

Reduce human errors and increase production repeatability

Automatically send setpoints and programs to the machine’s PLC

Control machine and send its PLC recipes

Make automated changeovers on-the-fly

Reduce changeover time significantly

Eliminate human errors by setting machine setpoints automatically

Reduce time spent on management of recipe changes

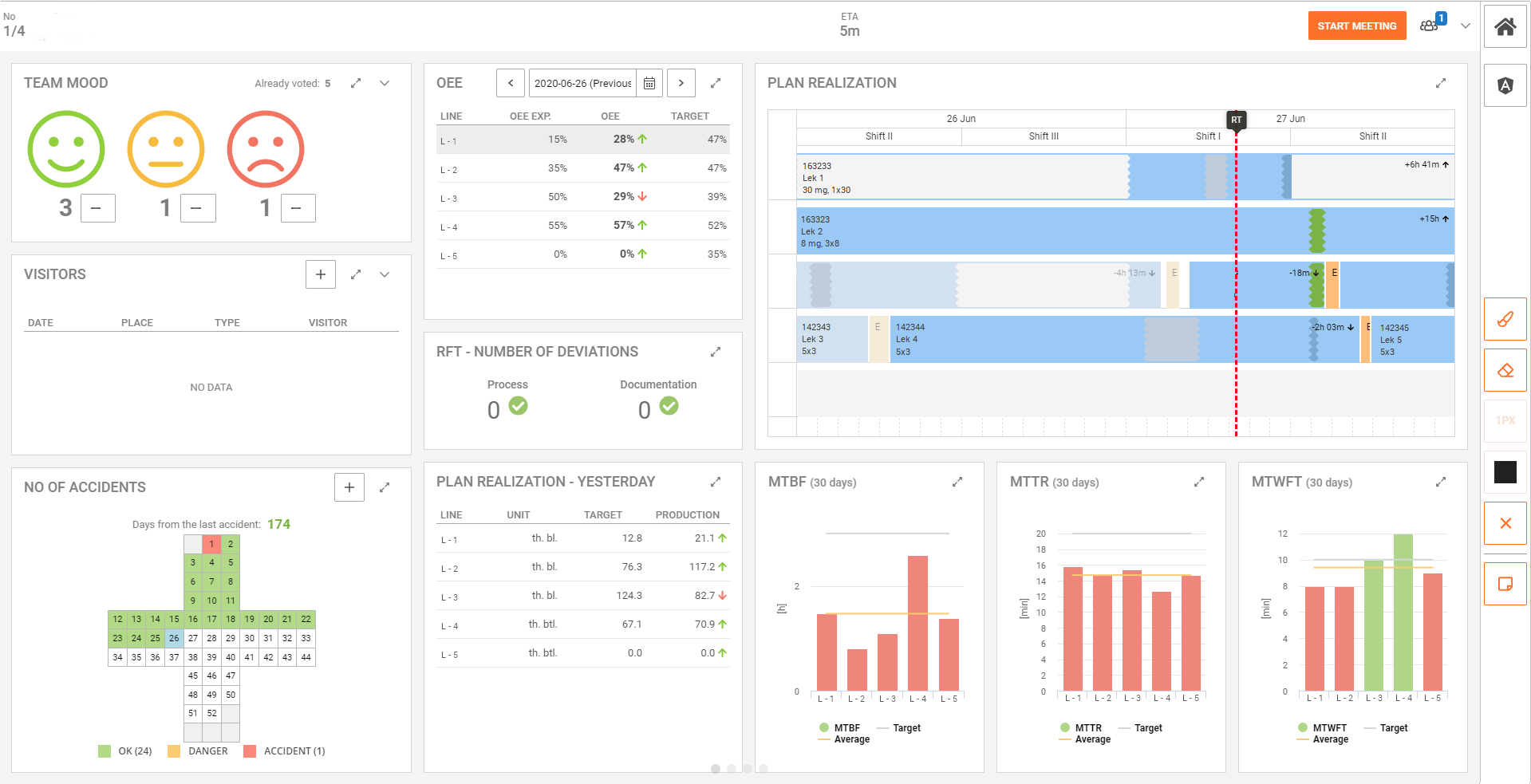

Organise a daily meeting with agenda and an automated filled dashboard

Generate charts automatically with real-time data feed

Monitor team’s tasks and their progress

Eliminate whiteboards from production with touchscreen

Decrease time spent on daily meetings and shift changes

Increase employees engagement through production transparency

By providing your email and clicking the “Sign up” button, you agree to subscribe to our newsletter to receive the latest news and useful insights about manufacturing.

By providing your email and clicking the “Download a catalogue” button, you agree to receive our newsletter.