The successful MES implementation depends on several factors – from the correct implementation of the data being collected to the precise analysis of the information. What should be considered when planning manufacturing process modelling? MES provides a number of advantages in this respect, but a few fundamental principles must be maintained.

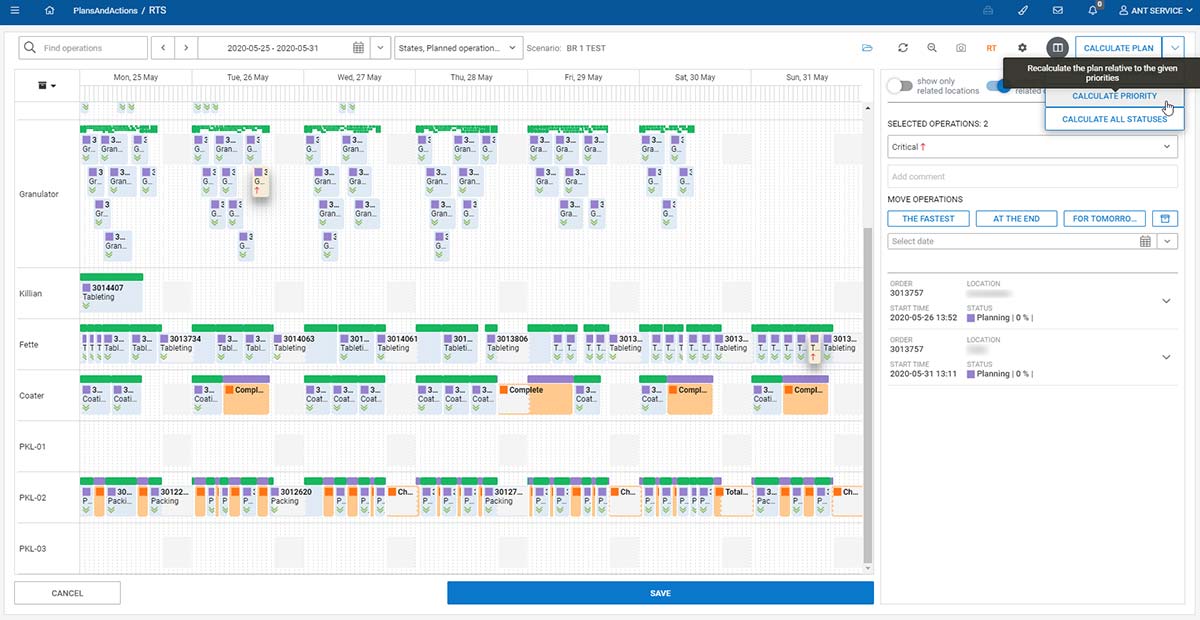

What is the correct MES implementation? This – very frequently asked – question can be reduced in practice to four basic steps. The first one is the acquisition of data from the machines – the automatic generation of data for subsequent analysis. The second and third steps are proper process modelling and production reporting. The fourth – and final – step is data analytics.

MES has to be looked at as a process that raises questions primarily in the context of Enterprise Resource Planning. MES implementation raises questions such as where to store information on production technology. These include assumptions regarding routings, BOMs, and a production plan. This leads to another question – regarding decisions to make when part of the production data is stored in the ERP system. However, a more detailed description of the process is necessary.

ERP or MES – where to model production data?

When analyzing ERP related dilemmas in the context of MES, you should first of all bear in mind that these are not hostile spheres, generating data conflicts or leading to reporting chaos. Instead, ERP should be viewed as an overarching system, with any data modelled remaining there permanently. MES, on the other hand, should enable us to model the data we need to describe the production process in more details. In the case of no ERP being in place, an MES may be implemented as a standalone solution with an integration applied at a later date.

The key issue here is to make sure that double reporting is avoided. In practice, it comes down to not maintaining identical data on multiple systems.

ERP or MES – where to model production data?

The MES solution has gained popularity, especially due to its extremely wide range of possibilities in the context of production. In case replacing or upgrading the ERP is planned there is no need to wait with MES implementation. MES is a standalone tool that makes ERP optional during implementation and can work on its own structures for production technology. However, it should be noted that the possibility to integrate with ERP is one of the main advantages of MES and should be done as soon as possible. MES can be also used to describe process in more details.

World-class MES solution allows you to model all the necessary data and in the case of two-way integration with ERP, it allows back and forth data transfers. In a situation where ERP is not integrated, it is possible to import standardized, prepared by ANT, Excel files with technology to quickly feed the system.

What is needed to create a basic description of the production model?

If we look at the production process from the perspective of the factors and data that are necessary to create the model, the following parameters of the production process can be highlighted.

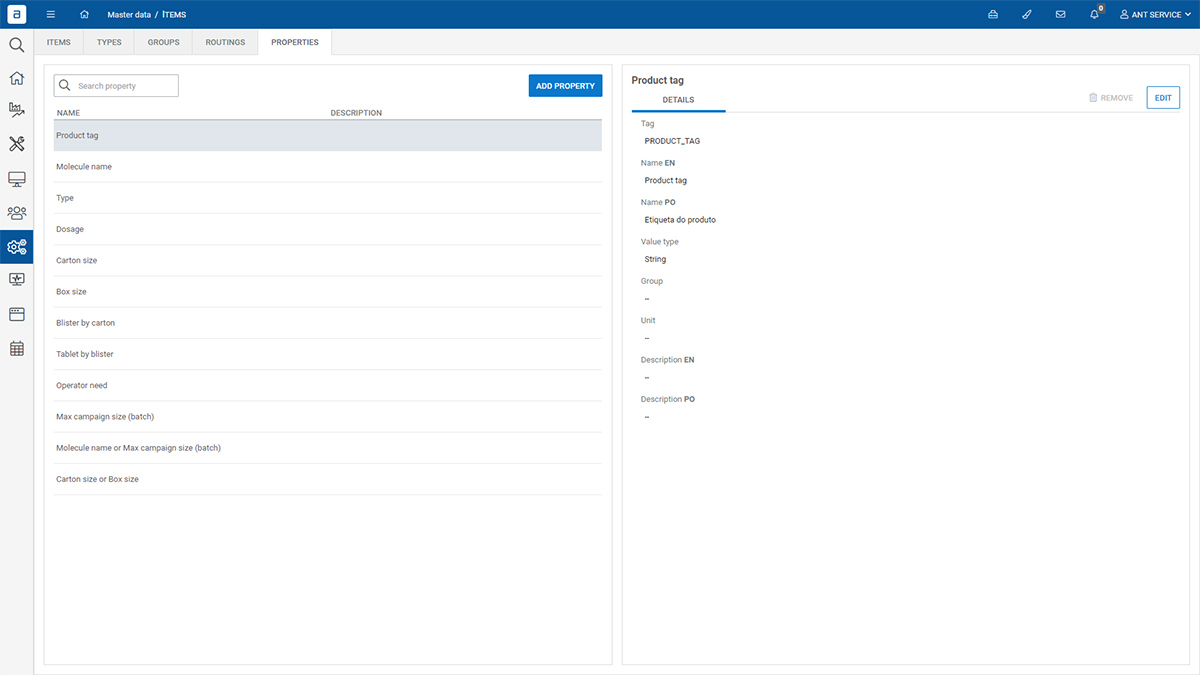

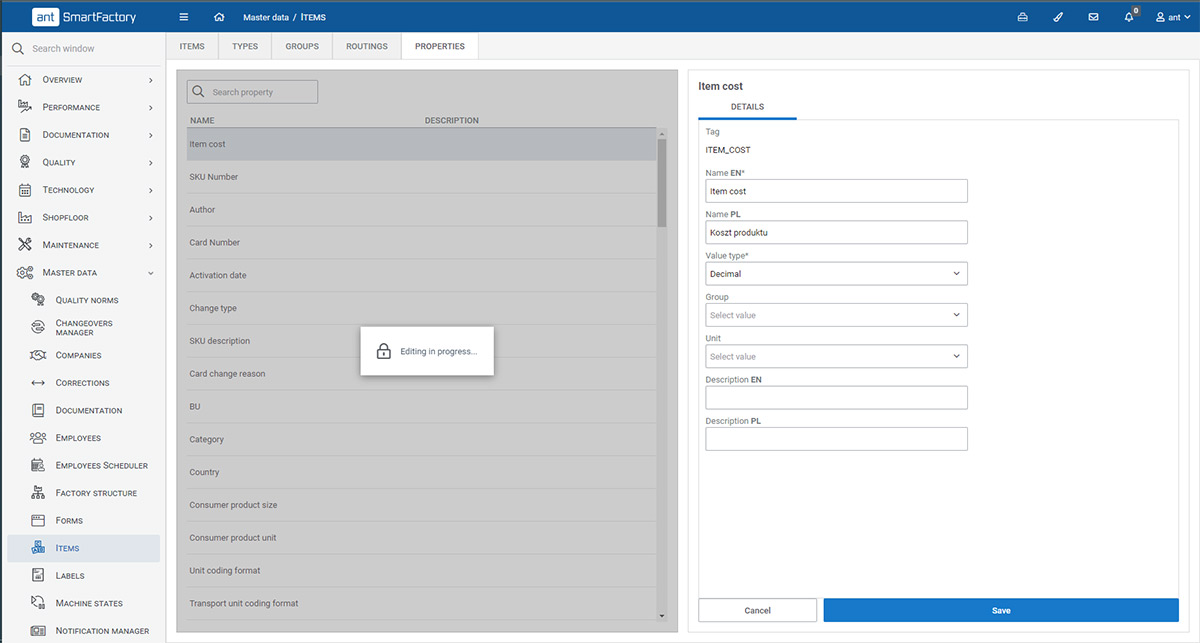

Items and materials

This group includes all finished products – and semifinished products – and materials, tools, or other components needed for a production process. Each type and group of these items can be further described by any properties, which are added to the system.

Routings

It should be understood as a description of all steps in the production process that are required to produce semifinished or finished goods. It can therefore be considered as a list of operations that are performed in a specific order and that take into account the times of changeovers, cycles, or specificities of individual tasks.

Structure of the factory and machinery park

The configuration of the factory structure is essential for effective modelling. It must be seen in a comprehensive way: starting with the group, the plant, the individual departments, and ending with lines, machines, or even individual parts in a machine. In practice, it can be assumed that each level identified in this way may have its own properties. These define the individual objects. Consequently, the structure is built like a tree, and relationships between objects remain its core feature.

Personnel

Up-to-date employee data is important for MES. Naturally, all information about the personnel of a given company should be stored – this includes names, proximity card IDs. The system allows managing their positions and roles, as well as building teams and managing their skills. All data and records can be extracted from the employee team management system as part of the HR policy.

Orders

Creating and managing orders within the system means, for example, assigning them to particular types – they may relate to sales, production, quality, maintenance or other data. Each order involves at least one operation. A production order in MES includes, for example: position code, routings, machine or line data, data and time needed to manufacture, quantity.

Other data needed for modelling

Naturally, an in-depth assessment of the machine states is significant for analysing production availability. This allows a quick and precise decision to be made as to which element may be affecting, for example, a decrease in efficiency.

Documentation is of equal relevance. It should be seen from the perspective of solutions accelerating the circulation of documents and their analysis. This includes, for example, uploading any PDF files, videos, images for the machine, position code, or role in the system. Importantly, the MES allows you to perform integration with an external system or by accessing a shared folder. As a result, the user gains the ability to categorize and display documentation on the operator panel according to their needs. All such processes are fully controlled. Production monitoring covers any changes to the documentation.

It is difficult to see the efficiency of operations without considering production targets. These can be set up for each machine or line and then used to measure whether a target has been met. In this way, the operator is able to compare the data with current production. This kind of analysis can be presented, for example, on a screen in the production hall.

An MES is also a very good way to model unit conversions. How effective is it? Imagine a situation where an operator has a blister containing 12 tablets. A single box can have four blisters, and one master case contains 24 boxes. Ultimately, the entire palette contains 150 boxes. Quick access to this type of aggregated data can be invaluable.

In addition, MES is highly relevant to processes that are theoretically minor but also affect the overall work. It gives, for example, the possibility to manage and plan changes and employee schedules by means of a competency matrix. Notifications can also be used to quickly send any information with regard to issues – so it provides the option of distributing information and alerts within the production company. Last but not least, there are also available defects glossaries with categories and states of defects. Thanks to this, you can decide whether the defect is leading to scrap or rework.

What is needed for a detailed description of a production process?

The Bill of Materials (BOM) is a basic document. It defines all the elements that are necessary to carry out a specific production process. It is therefore a complete list of raw materials and components, as well as sub-assemblies or parts, used in the manufacture of the final product. Furthermore, it is used to validate components used in the production process.

Another of the elements are labels: codes, names, matching with other parameters or customers. Effective label management is essential to achieve full validation of the materials and tools used.

At an advanced level of modelling, quality norms and limits are indispensable. They illustrate specific features of the processes along with a detailed description of the measurement procedure. This type of standard can be described in terms of several levels of data tolerance. Based on the data obtained in this way, it is possible to produce an SPC report with a histogram of the measured parameters.

Sets of machine parameters are also necessary to launch items in production. They help to standardize the production process and improve repeatability by enabling each operator to use the same settings. Deep integration with the PLC drivers allows programming automatically setpoints directly on the PLC.

Master system and complementary system – conclusion

In conclusion, it’s clear that data modeling and storing can be a significant factor that will decide the success or failure of the MES implementation. What is more, ERP should be treated as a master system and MES should be used to describe the production process in more detail. Therefore, integration between ERP and MES should be a must-have, in the case that exchanging, or actualization of ERP is planned, it can be postponed.

Products in this Article

Manufacturing Operations Management System (MOM)

Manufacturing Operations Management System (MOM) The most complete manufacturing solution with full support for operations management and a link between industrial automation and business operations

OEE Performance monitoring

Performance Monitoring (OEE) Connect and gather data from your machines. Schedule a Demo They Trusted Us: Key Benefits OEEincrease ✔️ shorter downtimes ✔️ faster production

MES System – Manufacturing Execution System – ANT Solutions

System MES – Manufacturing Execution System 0 % operating time increase 0 % defects quantity reduction 0 % material consumption reduction 0 % changeovers time