Full availability of the machinery park, control over downtime and maintenance lead times in the event of technical problems – these elements are among the key factors in optimizing production. Of particular importance is the correct work of the maintenance department. As you know, this data is fully measurable and subject to analytics.

Full machine availability and readiness for operation is desirable and even fundamental in any industry. Failures are a challenge that has a direct impact on the availability and timely execution of a specific production order. In this context – to assess how maintenance is performing in a company – KPIs should be measured. Based on these results and an analysis of the most frequent failures, an action policy – an improvement plan to increase machine availability – can be drawn up.

Full machine availability and readiness for operation is desirable and even fundamental in any industry. Failures are a challenge that has a direct impact on the availability and timely execution of a specific production order. In this context – to assess how maintenance is performing in a company – KPIs should be measured. Based on these results and an analysis of the most frequent failures, an action policy – an improvement plan to increase machine availability – can be drawn up.

How to measure maintenance times?

1. MWT (Mean Waiting Time) is the mean period from the occurrence of a failure to the logging on to the system using the machine.

2. MTTR (Mean Time to Repair) is the mean time from the occurrence of a failure to its repair.

3. MTTF (Mean Time to Failure) – an indicator of the average period from the end of repair to the recording of the next failure.

4. MTBF (Mean Time Between Failure) – the average time calculated from failure to failure.

Given that these are key factors in the context of KPI analysis, it is essential to operate using a system that provides full automation of work and of data generation.

Capabilities of the ANT ANDON module

The modular ANT solution is designed to measure maintenance time when emergency response and rapid repair is required. The analytics system provides functionality tailored to generate data and draw conclusions:

- failure reporting with cause and commentary prepared in order to ensure faster reaction and quicker repair

- acceptance of maintenance failures reasons and their closure

- monitoring response time, repair time and its KPIs in terms of the mentioned parameters MWT, MTTR, MTBF, MTTF

- managing machine repair history

- analysis of factors such as repair times, equipment status, cause of failure

- suggestions to the technician based on the failure history and recent events

This solution stands out for its individual approach to specific problems. An example is a separate mode for reporting faults, which requires maintenance but, importantly, has no specific impact on ongoing production. It will therefore be a symbolic and relatively minor failure of the equipment.

In addition, analytics module is an important feature. These include Pareto charts developed in terms of causes of failure, which are sorted by machine and individual items. The system can also display documentation and generate ongoing alerts, which can be sent to mobile devices with push notifications.

An integration of MES with an external CMMS is important for measurement efficiency. When analyzing this step by step, one can note:

- reporting a failure in ANT Smart Factory

- sending this information to the CMMS

- execution of the workflow in the CMMS

- sending information to the ANT Smart Factory at the end of a CMMS failure to release the blocked station

The implementation of the system translates into real and tangible benefits in terms of the operation of the maintenance department. This is because it leads to a better selection of the team of technicians – checking the qualifications required for the failure and better verification of attendance on the current shift. A noticeable change is also the estimated repair time – the technician can report the estimate to provide digital feedback to the planner. It allows updating of the production plan, which plays an important role in showing the risk of not finishing the production order on time.

The system also operates on the basis of escalation. If a sample fault is not accepted for action within 10 minutes, a notification is sent to the foreman. When there is no acceptance for half an hour, an automatic notification goes directly to the maintenance manager.

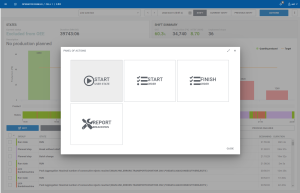

How ANT Maintenance ANDON works.

ANT system workflow for failures:

- A downtime occurs

- As a result, the operator reports the cause of the downtime as failure – defining it as a mechanical, electrical, code-related or other problem – and, if applicable, confirms the cause and the need for service assistance. This is the case when the cause of the fault is not recordable from the direct PLC

- System sends a notification to departments or dedicated individuals via a text message, a push message to a smartphone, an email, a phone call, a notification on a monitor in the maintenance department or on the shop floor

- Measurement of WT and TBF starts if the machine is not running

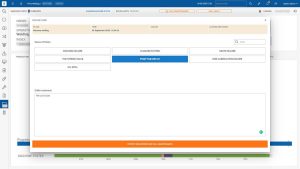

- The maintenance service carries out the process of logging into the operator panel. On this basis, the cause of the failure is confirmed – this is done using an RFID card or NFC tag. This stops the WT measurement, and at the same time the TTR measurement is started

- Flexibility is an important issue. Of course, maintenance services can change the type of recorded problem. It may therefore be forwarded to another unit. So, for example, if a given order is not for mechanics but for electricians, the transfer of information takes place in a fast and flexible manner

- When the maintenance service completes the repair, the measurement of TTR ends and the measurement of TTF starts. However, in the event of another failure, the Measurements of both TTF and TBF are terminated.

- A critical issue in this context is the calculation of KPIs. The system analyses them according to the following assumptions:

- MWT (Mean Waiting Time) is the total waiting time in relation to the number of failures

- MTTR (Mean Time To Repair) is the total time to recover data against the number of failures

- MTTF (Mean Time To Failure) is the total time to failure in relation to the number of failed modules

- MTBF (Mean Time Between Failures) is the total time between failures versus the number of failures

What are the benefits of implementing a maintenance time measurement system?

Undoubtedly, the main advantage is the much faster reaction of the service to recorded failures thanks to notifications. The full maintenance history and knowledge is stored in a single system and is fully reduced to a digital record.

Implementation examples also show faster service repair times thanks to suggested failure history and documentation. This also translates into learning lessons for the future. Universal KPIs and Pareto charts provide a precise indication of the most common causes of failure and those components that appear to be most vulnerable. These are the potential areas that need systemic improvement.

Products in this Article

OEE Performance monitoring

Performance Monitoring (OEE) Connect and gather data from your machines. Schedule a Demo They Trusted Us: Key Benefits OEEincrease ✔️ shorter downtimes ✔️ faster production

CMMS System for Maintenance Management

Computerized Maintenance Management System (CMMS) Plan, manage and react with CMMS System by ANT. The best maintenance system for equipment performance in your factory. It

Machine control

Machinecontrol Take full control over your machine park Machine Supervision System –make production more effective, automatically! Controlling production processes is necessary to guarantee a high-quality