Software

for Industry 4.0

Modern industries expect industry 4.0 solutions to meet actual market requirements and changes. ANT is facing with it thanks to modular build, configurable software solutions and scalable platform

What is Industry 4.0 and why is it important?

Industry 4.0 is the fourth industrial revolution, and it is characterised by the convergence of digital and physical technologies for manufacturing industries. This includes technologies such as the Internet of Things (IoT), digital twins, cloud computing, artificial intelligence (AI), predictive maintenance and machine learning leading to mass customisation possibilities .

Industry 4.0 is transforming the way that businesses of all sizes operate. By implementing Industry 4.0 technologies, businesses can improve their efficiency, productivity, deal with production issues and competitiveness.

The key factors of include:

- Autonomous machines: Autonomous machines work with people and learn from them. This allows machines to perform tasks that were previously done by humans, and to perform tasks more efficiently and accurately.

- 3D simulation: Digital twins enable virtual planning and testing of production. This allows businesses to optimise their production processes and to identify and resolve potential problems before they occur.

- Integration of information systems: Industry 4.0 integrates information systems at every level, from suppliers to customers. This allows businesses to have a holistic view of their operations and to make better decisions.

- Industrial Internet of Things: The Industrial Internet of Things (IIoT) is a key component of Industry 4.0. The IIoT connects machines and devices to the internet, allowing them to collect and share data in real time. This data can be used to monitor and improve manufacturing processes, supply chains, and customer service.

- IT systems for production optimisation: A manufacturing company can use an MES system to automate its production processes. The MES system can collect data from machines and sensors on the factory floor and use this data to control the production process.

- Augmented reality and big data: Augmented reality (AR), digital twins and big data are also important components of Industry 4.0. AR can be used to provide workers with real-time information and instructions. Big data can be used to analyse data from the IIoT and other sources to identify trends and patterns.

A smart factory is using a variety of sensors to collect data from its machines. The sensors collect data on machine performance, energy consumption, and product quality. This data is transmitted to a central server using a wireless network. The server analyses the data in real time and provides insights to factory managers. The managers use this information to improve efficiency, introduce predictive maintenance practices, increase productivity, and quality. Industry 4.0 solution is characterised by:

- Connect machines to focus on machine data collection

- Communication with new and old machines

- Counter and process parameters read from PLC, HMI, electrical cabinets

- Dedicated solutions: sensors, acquisition boxes, cameras

- Modern IoT architecture with data offline buffering

The benefits of using software for Industry 4.0

- Increased efficiency: Smart manufacturing solution can help businesses to automate tasks and streamline processes, which can lead to significant efficiency gains.

- Improved productivity: Industry 4.0 software can help manufacturing industry to improve their productivity by providing them with real-time data and insights that they can use to make better decisions.

- Reduced costs: Smart factory software can help businesses to reduce their costs by optimizing their operations and eliminating waste.

- Improved quality: Third industrial revolution software can help businesses to improve the quality of their products and services by providing them with real-time data and insights that they can use to identify and correct problems early on.

- Increased customer satisfaction: Industry 4.0 software can help businesses to improve their customer satisfaction by providing them with a better understanding of their customers’ needs and by enabling them to respond to those needs more quickly and effectively.

Different types of SOFTWARE for Industry 4.0

- Manufacturing execution systems (MES): MES systems provide real-time data and insights into the manufacturing process. This information can be used to optimize production, improve quality, and reduce costs.

- Enterprise resource planning (ERP) systems: ERP systems integrate all of the core business processes of a company, such as manufacturing, accounting, and sales. This can help businesses to improve efficiency and visibility across the entire organization.

-

Computerized Maintenance Management System (CMMS): CMMS helps organizations plan, track, measure, and optimise everything to do with maintenance on a preventive basis. In the real of smart factory it allows to schedule predictive maintenance activities and it is instrumental in scheduling, assigning, and closing work orders, managing the workforce, and ensuring that maintenance is conducted effectively and efficiently.

-

Industrial Internet of Things (IIoT) platforms: IIoT platforms connect and manage IoT devices. This data can be used to improve manufacturing processes, optimize supply chains, and develop new products and services.

- Artificial intelligence (AI) and machine learning (ML) software: AI and ML software can be used to analyze data and identify patterns and trends. This information can be used to improve decision-making, automate tasks, and develop new products and services.

- Read more at Modern Production Systems

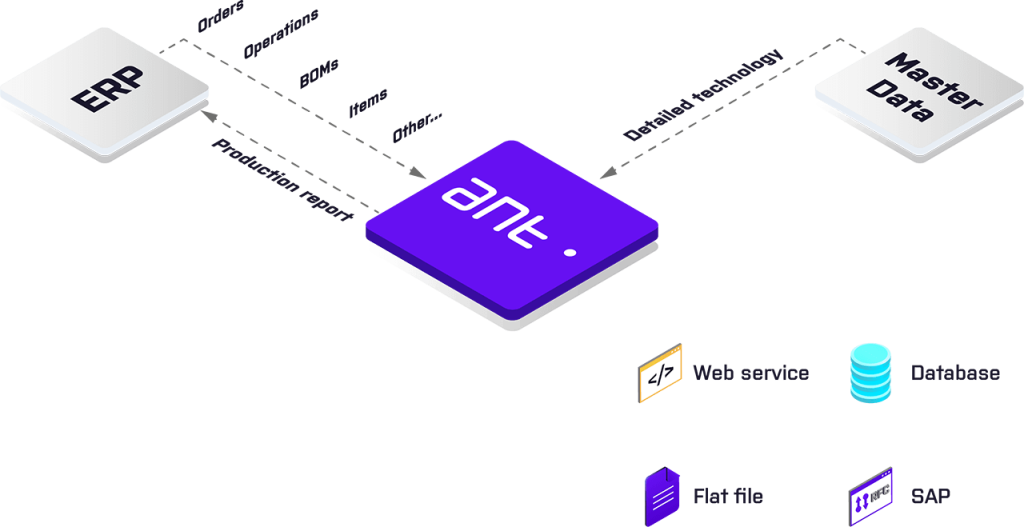

Systems Integration

System integration is important for the Industry 4.0 concept because it allows businesses to connect their different systems and share data. ERP systems are used to manage all of the core business processes of a company, such as manufacturing, accounting, and sales. ANT Solutions is a software company that provides Industry 4.0 solutions, including ERP systems. ANT Master is a data integration platform that helps businesses to connect their different systems and share data.

System integration is important for the Industry 4.0 concept because it allows businesses to:

- Automate tasks and streamline processes: By connecting their different systems, businesses can automate tasks and streamline processes, which can lead to significant efficiency gains.

- Make better decisions: By having access to real-time data from all of their systems, businesses can make better decisions. For example, a business can use data from its ERP system to make decisions about production and inventory levels.

- Improve maintenance: By connecting their CMMS system to their other systems, businesses can provide better maintenance. For example, connecting machine to CMMS and other systems, smart machine can help to set predictive maintenance activities.

- Develop new products and services: By having access to data from all of their systems, businesses can develop new products and services that meet the needs of their customers. For example, a business can use data from its CRM system to identify customer needs and develop new products that meet those needs.

How to choose the right software for Industry 4.0 for your business

All companies can implement digital transformation solutions, regardless of their size or industry. However, some companies are better positioned to implement modern systems than others. For example, companies that have a strong digital foundation and a culture of innovation are more likely to be successful in implementing Industry 4.0.

When choosing the right software for your factory, there are a few things you should keep in mind, including:

- Cloud support: Cloud-based software is becoming increasingly popular because it is affordable, scalable, and accessible from anywhere.

- User-friendly dashboards: The smart manufacturing solution should have clean and user-friendly dashboards that make it easy to visualize and analyze data.

- Automated deployment: The software should have automated deployment mechanisms that make it easy to deploy new versions of the software.

- Modern programming languages: The software should be developed using modern programming languages, such as JavaScript, TypeScript, Node.js, and React. This will make it easier to find and hire developers who can work with the software.

- Mobile support: The software should be able to run on mobile devices, so that users can access it from anywhere.

Case studies of businesses that have successfully implemented Industry 4.0 software

Biscuits Factory

- Find out what problems bicuits factory was facing before implementation OEE factory software.

- What was ANT Solutions approach to deal with uncovered factory issues.

- How ANT Solutions implemented the key software components including hardware and cabling.

- The final outcome resulted in key KPIs increase.

Meters Factory

- Company implemented an MES system to improve manufacturing efficiency.

- The MES system enabled real-time production monitoring, quality inspections, and defect handling.

- The MES system helped factory to increase efficiency, reduce defective products, and improve data accuracy.

- Find out how ANT Solutions MES implementation, helped manufacturer increasing it’s KPIs.

Tobacco Plant

- This case study describes the customer case study of a successful micro stops implementation in a tobacco factory.

- The factory system enabled automated data gathering and key algorithmics.

- The system was implemented to address the challenges of high-speed production, micro stops, SKU and changeover times, and a diverse machine park.

- Find out how ANT Solutions enabled communication with over 100 machine types, algorithmics creation, and roll-out to 30 factories.

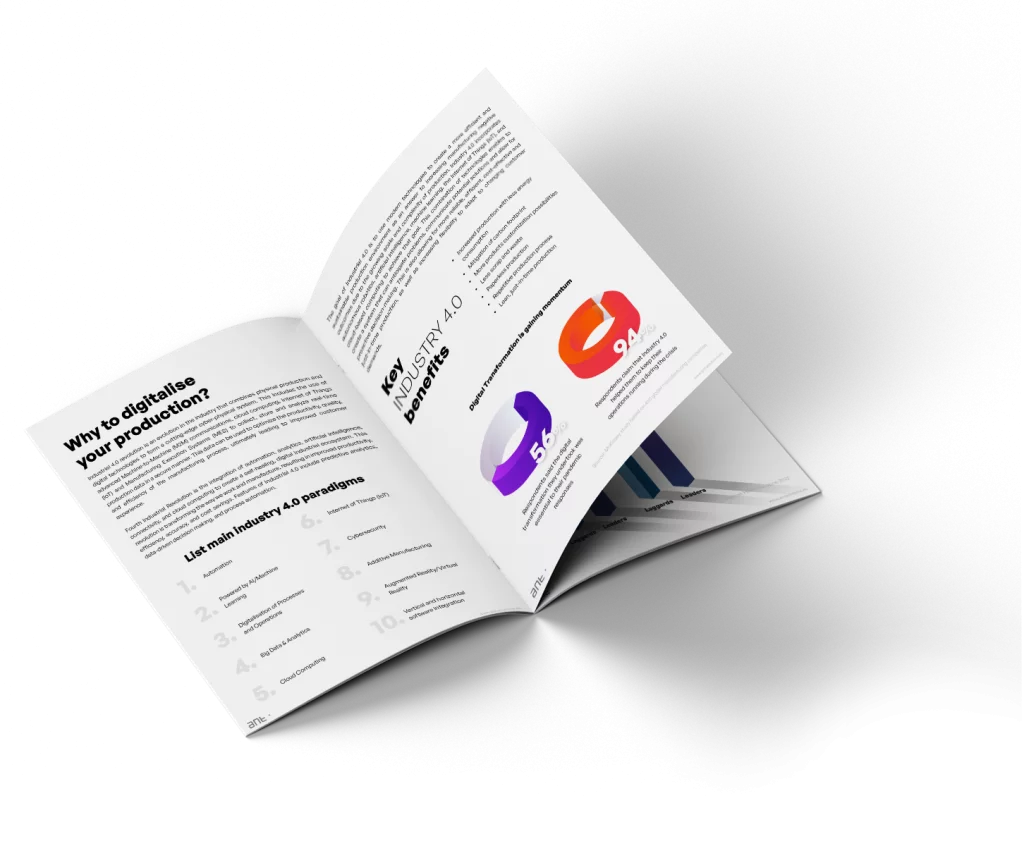

Download also Factory Digitalisation Guide and Smart Factory Report With ROI