Bahlsen, a renowned leader in the biscuit industry, is upgrading its factory in Skawina by integrating a modern Statistical Process Control (SPC) system into its Manufacturing Execution System (MES). This technology solution is being implemented in collaboration with ANT Solutions, a leading company in manufacturing software.

Key improvement: Expansion of the “Bahlsen Smart Factory” MES system.

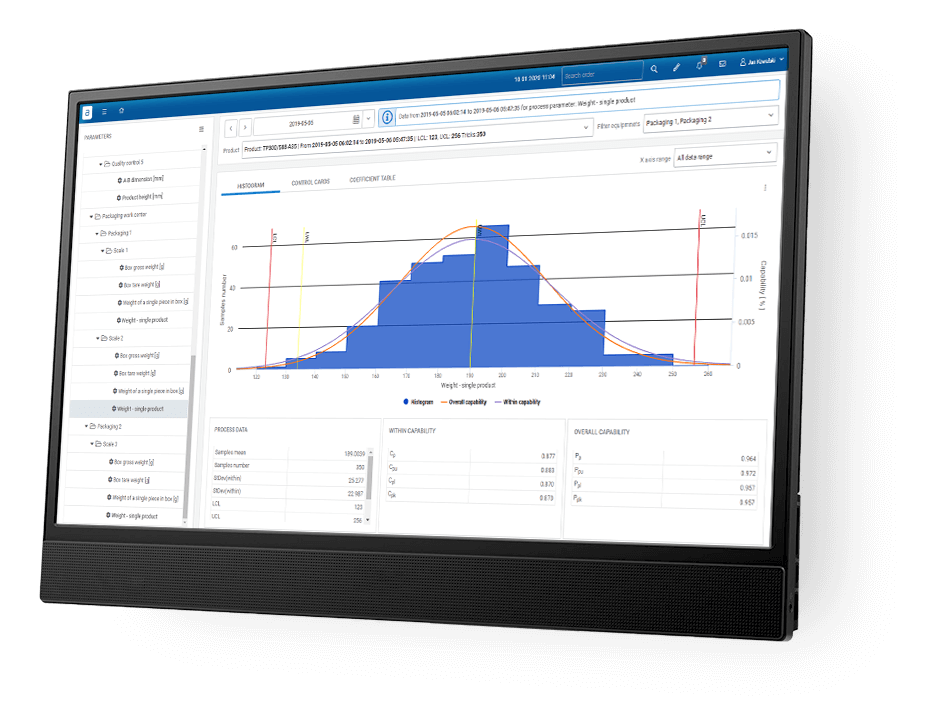

The main focus of the update is to expand the existing MES system, called “Bahlsen Smart Factory,” by adding a Statistical Process Control (SPC) module on all production lines in the Skawina plant. This step aims to replace the factory’s existing, no longer supported SPC system and expand it with features that allow for more effective and employee-friendly analysis and decision-making. Now, most production processes will be effectively monitored by one integrated “Bahlsen Smart Factory” system.

The goal of the enhancement

The primary goal of this enhancement is to ensure the highest quality standards in biscuit production by introducing new tools for statistical control of the production process. The greatest benefit of the new solution is prevention and the ability to predict potential defects before they occur.

The importance of quality monitoring in FMCG production

In the fast-moving consumer goods (FMCG) industry, especially in food production, maintaining consistent quality is crucial. The main reasons why quality monitoring is important are:

-

- Consumer safety: Ensuring that products are safe to consume and free from contaminants.

-

- Brand reputation: Maintaining high quality is key to preserving the brand’s image and customer trust.

-

- Regulatory compliance: Adhering to strict food safety and quality standards set by regulatory bodies.

-

- Minimising waste: Effective quality control helps reduce production errors and waste-related losses.

Why the ANT Solutions system is the choice for Bahlsen Polska

The ANT Solutions system stands out with its comprehensive approach to quality control in production. Benefits of using such a system include:

-

- Integrated monitoring: A unified platform for monitoring various aspects of production, ensuring consistency and reliability.

-

- Data-driven decisions: Access to real-time data and analyses, such as SPC analysis, aids in making informed decisions that optimize production.

-

- Scalability: Flexibility to adjust and scale according to the evolving needs of the plant.

- Increased productivity: Automation and advanced tools lead to increased efficiency and productivity.

The collaboration between Bahlsen Polska and ANT Solutions is a constant element of the company’s strategy to refine processes at the Skawina factory, known as the “B.Excellent” system. The integration of systems demonstrates the company’s commitment to quality, efficiency, and innovation, which will undoubtedly keep Bahlsen at the forefront of confectionery producers.