Transparency in manufacturing may sound like a marketing ploy, but it actually brings tangible benefits, from smoother workflows to significant financial savings. If transparency in manufacturing is so important, it is worth reaching for (often surprisingly small) changes that dramatically transform the reality of the process.

Labor efficiency, financial benefits, better control over manufacturing activities – these are just some of the benefits of a transparent shopfloor. It is hard not to notice that this translates directly into significantly greater participation in the performance of tasks. That is because of the precise analytics: data collected in real time is not hidden, it is fully accessible to everyone on the shopfloor. What is more, the data is an excellent basis for drawing conclusions on how to optimize shop floor management – decisions become easier and faster. This is important, among other things, in connection with the operation of machinery. Their work and efficiency become fully visible and easily comparable, e.g. with others – both lines and e.g. shift teams. Ultimately, all these factors can be converted to a common denominator. That is goal achievement, seen through the prism of KPIs. They show the results and the room for possible change.

Transparency in manufacturing in the light of market requirements

There is no doubt that the importance of transparency is growing. The main challenges to increase production transparency are:

- lack of consistent KPIs and targets

- lack of real-time data

- too many systems for analysis

- gaps between systems

- lack of integration between systems

How to counteract this? In the context of KPIs and the lack of consistent targets, it is worth explaining to employees – and preceding this with a discussion – why the parameters are so important and subject to irrevocable analysis. This, of course, requires clarification of basic factors – such as:

- OEE – a universal KPI that answers the question of what state production is generally in

- performance – actual cycle time or production rate compared to planned technology

- availability – actual production time compared to previously planned time

- quality – correct execution of elements in relation to the total production volume.

How else to ensure transparent operations in a factory?

Lack of real-time data

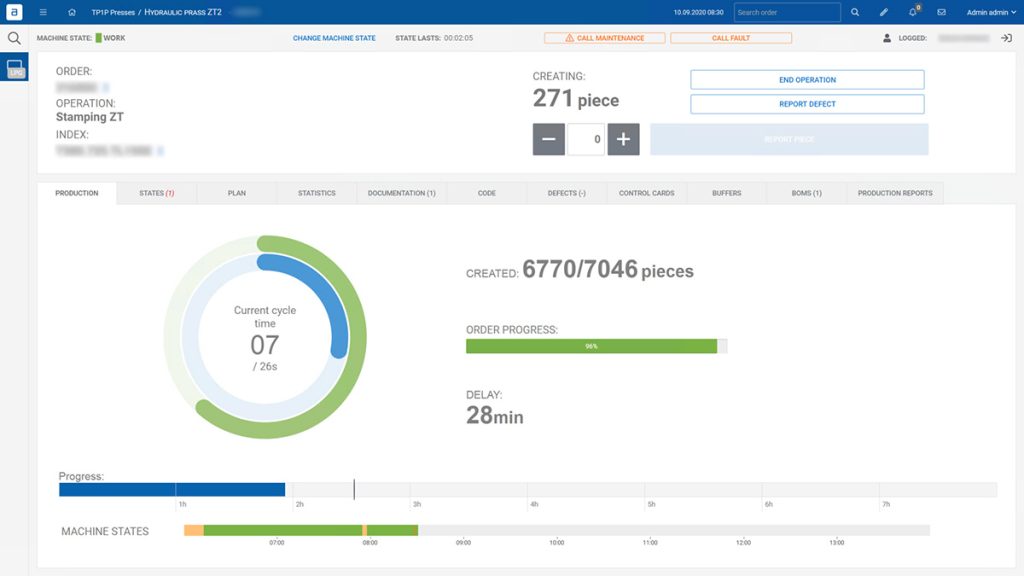

The solution is to consistently collect automatically received data in real time. This can be done automatically by connecting to PLCs and sensors or by collecting data manually by the operator. This is made possible by the operator’s panel.

Too many complex systems

If there are too many complex systems being analyzed, it is easier for chaos and errors to occur. Meanwhile, a standard manufacturing company has to use many different types of systems. These include MES, ERP, APS, CMMS, SCADA, WMS and others. To get a comprehensive overview of the company, you need to know virtually all of them – so you should select the most important data that is critical to understanding the production condition at a glance.

Gaps between systems and lack of integration

The result is not just delayed information. The problem also arises in the context of double reporting. Automation can help avoid this. If you find a lack of automatic dissemination of data between systems, you should think about cross-system interfaces that enable the automatic exchange of information.

How can you improve transparency in production step by step?

Improving better transparency, which will later bring a number of benefits, requires both a change in approach to information flow and the implementation of technological solutions.

The first step should be to select the right KPIs and – preceding a selection – generate those data that can be considered the most important for efficient operations on the MES shop floor.

It is equally important to standardize the perception of activities on the MES shop floor. The focus should be on the information that helps to quickly assess progress. Among other things, the following should be monitored:

- changes in the execution of production orders

- the achievement of targets

- OEE levels of a department or the entire factory

- condition of machines and production lines

- total downtime

- delays and their causes.

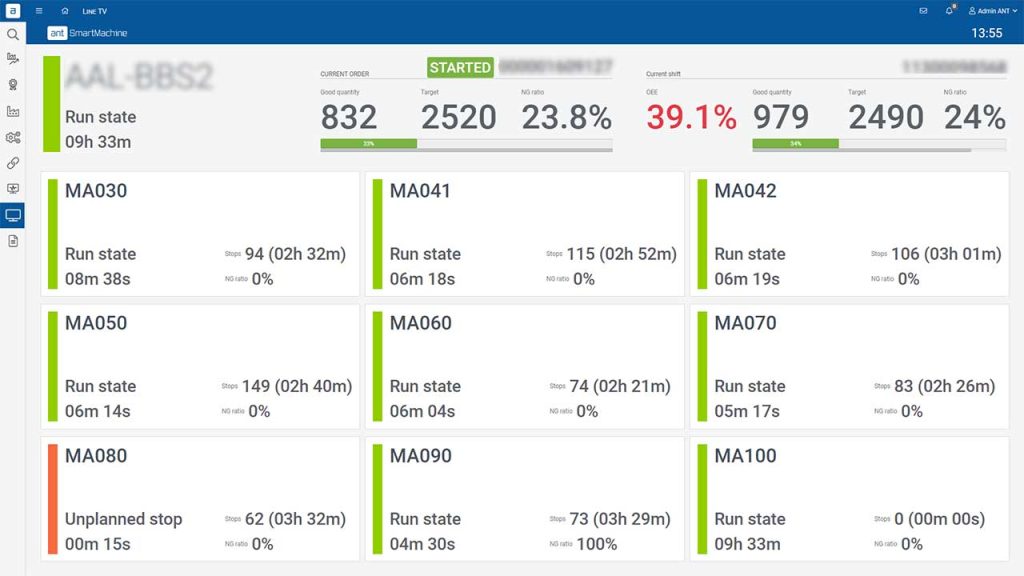

It is important to give employees a direct insight into their results through operator panels and install TVs to quickly assess KPIs, machine states, problem locations and to facilitate decision making.

Increased production transparency thanks to ANT

The main feature of the ANT solution is automation, which takes place at several levels. In the first level, production KPIs are implemented – including OEE and quality, maintenance and productivity parameters. The automated data collection itself is done by connecting to machines and data entry by operators. The result is the calculation and display of KPIs in real time.

Importantly, the implementation is not an IT revolution. There is seamless integration of the MES with systems used in the factory. So there are no problems caused by the need for double reporting – the system is responsible for clearly presenting key information from other systems.

Information and overall navigation – transparency of data flow and accessibility – play an important role in this architecture. On the shop floor, this is provided by ready-to-use dashboards viewed on the 65-inch screens that are proven and tested in factories around the world. The convenience of drawing conclusions is facilitated by a single shop floor MES – designed for the entire shop floor management: from documentation to orders and production planning to quality control.

What are the benefits of transparency in production?

The benefits can be divided into several groups. The main benefit is more effective shop floor management. This applies to the management of not only individual shifts but to the entire production facility.

A natural consequence of the implementation is definitely greater operator responsibility for the process and the machine being operated. Transparency also has an impact on interpersonal relationships and the general building of trust within the team. Also worth mentioning is higher motivation of the operators – their work is visible, measurable and appreciated.

Analytics is a separate issue. The ANT system makes it easy to compare the calculated KPIs of a department, a factory or a group of factories. This finally puts an end to late or wrong data. It is all about maximum transparency – with a quick analysis, you can check the current state of production and see which areas need support.

ANT offers an unlimited number of users who have access to the system – so full transparency is not just a word but a real condition that changes the company for the better.

Products in this Article

MES System – Manufacturing Execution System – ANT Solutions

System MES – Manufacturing Execution System 0 % operating time increase 0 % defects quantity reduction 0 % material consumption reduction 0 % changeovers time

Manufacturing Operations Management System (MOM)

Manufacturing Operations Management System (MOM) The most complete manufacturing solution with full support for operations management and a link between industrial automation and business operations

Paperless Manufacturing

Paperless Manufacturing Streamline your manufacturing with ANT PAPERLESS. Digitize forms, improve communication, and access data securely from anywhere, creating a more efficient and sustainable operation.