Achieving high-quality indicators is an essential aspect of ensuring customer satisfaction and promoting further company growth. For this reason, modern production facilities implement further functionalities that focus on increasing accuracy and achieving better results. Fluctuations in quality lead to increased waste and thus additional costs. Wasting resources also hurts the OEE.

If a product that does not meet customers’ expectations is delivered, their complaints must be addressed based on facts on hand. However, this requires error analysis based on materials used, tools, production parameters, or machine operators. Things get complicated when detailed data is not available.

For this reason, production traceability is necessary. This allows you to track and trace from raw material to finished product (up-stream) and from finished product to raw material (down-stream). Thus increasing transparency of your production process.

Tracking and tracing in manufacturing

While they sound similar, tracking and tracing refer to different things that are related. Tracking monitors the progress and visibility of how a product moves between different operators during production. It also helps in the identification of the components and products’ location, as well as production order status and the operator who is currently running the machine. Moreover, tracking enables you to monitor the operation sequence and each machine and its set points during the entire production process, while ensuring that quality limits are met.

On the other hand, there is tracing, which is crucial in identifying materials and parts used in the supply chain. This opens the possibility of verifying and validating things such as the source of the material, its release from the quality control, conformity to the production order and tools used in the production process. In the case of a finished product, it refers to the verification of the conformity of production parameters concerning the permissible limits, which means maintenance of the quality of production.

How to reduce errors and increase the quality of work?

How to improve product quality and reduce errors? The historical data collected can be compared with the current production state to show its progress. The system stores information about operators and machine settings and records values for process parameters such as temperature, pressure, force, or speed.

Historical data helps to link the finished product with the tools, raw materials or the operators who contributed to the creation of a said item. The analysis of this information allows serialization of the production. It enables you to quickly search the production series or identify a single product.

Reducing errors is also possible with periodic quality inspections. The system helps to comply with IATF 16949 standards. How? By starting with requesting quality inspections after certain events, e.g., when a production line has been idle for more than 25 minutes or when an operator has detected three faults within an hour.

Labelling as means of tools and material validation

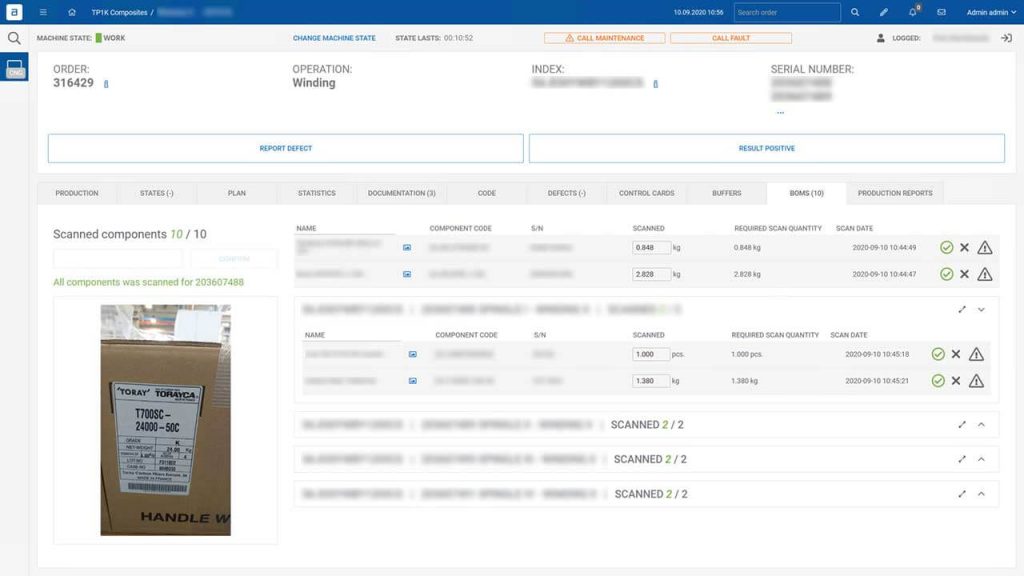

Validation makes it possible to identify the materials and components used in the production process and verify their origin and conformity with the items’ BOM. In addition, you can ensure that components have passed quality control.

How does labelling improve production quality? This method is effective for material and tool validation. Each item is identified with a 1D/2D label. As it travels through the production line, this code is scanned and the information on the label assigned by the system is then compared with the bill of materials (BOM). If the status of a given component meets the requirements, a message is sent to the operator to start the production. If, on the other hand, it turns out that the material has not passed quality control, that the expiration date has passed or that it is incomplete or defective, the employee also receives a corresponding message.

The production management system also contributes to buffers on the machine by regularly analysing the machines’ stocks and exchanging information with the warehouse about material supplies. In this way, the risk of a production stop due to insufficient raw materials is eliminated. Advanced technological software should also control, count and store data on the current number of tool cycles to predict the need for tool refurbishment or replacement on time.

The benefits of traceability in reducing the number of production errors

Production facilities use modern production management systems to reduce errors. Nevertheless, sometimes production line problems cannot be completely ruled out. Even then, with the help of software, you can take measures that will benefit the quality of your services. How?

Full traceability of suppliers and customers plays a unique role by facilitating activities in a batch recall. The up-stream and down-stream traceability allows to quickly find customers that get blocked component. This allows to respond quickly to complaints and be more transparent to the customer, which has a positive effect on the company’s image.

Analysis of production flow and critical areas allows defining quality gates throughout the production. Traceability helps not only to reduce the risk of human error stemming from using wrong or blocked components, but also offers a much easier and faster compliance process thanks to traceability upstream and downstream.

Easy access to historical data (SPC reports, control cards, machine set-points, BOMs, etc.) allows Root Cause Analysis of the production process to identify potential quality, technological and technical problems on the production line. Assigning a finished product to specific parameters, place, and production time allows analyzing the source of a potential problem, which can be:

- a poorly chosen tool for the specific application,

- incorrect machine settings,

- utilizing improper raw material.

Production with traceability – minimize your losses

Production will never be 100 percent error-free. Many factors can be at fault, such as the operator, the raw material supplier, an outdated machine and many others. Traceability allows minimizing losses and delays resulting from the inability to identify the source of the issue. If you are experiencing problems during production and are exploring ways how to identify them, contact ANT Solutions.

Products in this Article

Manufacturing Operations Management System (MOM)

Manufacturing Operations Management System (MOM) The most complete manufacturing solution with full support for operations management and a link between industrial automation and business operations

OEE Performance monitoring

Performance Monitoring (OEE) Connect and gather data from your machines. Schedule a Demo They Trusted Us: Key Benefits OEEincrease ✔️ shorter downtimes ✔️ faster production

MES System – Manufacturing Execution System – ANT Solutions

System MES – Manufacturing Execution System 0 % operating time increase 0 % defects quantity reduction 0 % material consumption reduction 0 % changeovers time