What is production optimisation?

Production optimisation is the process of identifying and implementing improvements to production processes in order to increase efficiency, reduce costs, and improve quality. It can involve a wide range of activities, such as:

- Streamlining workflows

- Reducing waste

- Improving machine utilisation

- Reducing downtime

- Improving product quality

- Reducing costs

Benefits of production optimisation

Production optimisation can have a significant impact on the bottom line of a business. Some of the key benefits include:

- Increased productivity

- Reduced costs

- Improved quality

- Shorter lead times

- Increased customer satisfaction

- Improved competitiveness

What is modern production software?

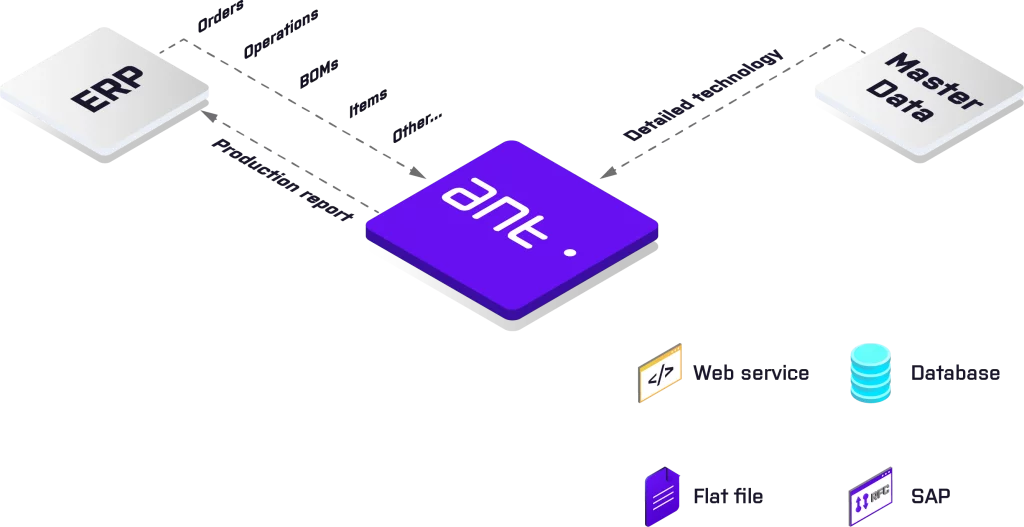

Modern production software is a suite of tools that can help businesses to optimise their production processes. It typically includes features such as:

- Production planning and scheduling (APS)

- Manufacturing execution systems (MES)

- Quality management systems (QMS)

- Maintenance management systems (CMMS)

- Warehouse management systems (WMS)

- Business intelligence (BI) and analytics

How to choose the right production software for your business

When choosing production optimisation software, there are a number of factors to consider, including:

- The size and complexity of your business

- The specific areas of your production process that you want to improve

- Your budget

- The level of technical expertise of your staff

It is important to choose a software solution that is scalable and can meet the changing needs of your business as it grows. It is also important to choose a software solution that is compatible with your existing systems and infrastructure.

Some of the most popular production optimisation software solutions include:

- SAP ERP

- Oracle ERP

- Microsoft Dynamics 365

- Infor LN

- QAD Enterprise Applications

How to implement production optimisation software

Once you have chosen the right production optimisation software for your business, the next step is to implement it. This process typically involves the following steps:

- Planning and preparation: This includes developing a project plan, identifying the key stakeholders, and communicating the changes to employees.

- Deployment and training: This involves installing the software and training employees on how to use it.

- Monitoring and continuous improvement: It is important to monitor the implementation of the software and make adjustments as needed. You should also continuously look for new ways to improve your production processes.

Case studies of businesses that have successfully used production optimisation software

A number of businesses have successfully used production optimisation software to improve their operations. Here are a few examples:

- Company A: A manufacturing company that produces medical devices used production optimisation software to reduce downtime by 15%. This resulted in an annual increase in productivity of $1 million.

- Company B: A food and beverage company used production optimisation software to reduce waste by 10%. This resulted in an annual cost savings of $500,000.

- Company C: A clothing retailer used production optimisation software to reduce lead times by 20%. This resulted in improved customer satisfaction and increased sales.

How to use modern production software effectively?

Here are some additional tips on how to use modern production software effectively:

- Start by identifying the key areas of your production process that you want to improve. This will help you to choose the right software features and focus your implementation efforts.

- Conducting a current state audit

- Determination of KPI values: OEE, MTBF, MTTR, MTWFT

- Identification of key areas where losses, errors or delays occur

- Preparation of a roadmap based on the analysis data

- Identify the priorities you care about

- Determination of next steps during optimisation of production processes, starting with the most critical areas

- Involve employees in the implementation process. They can provide valuable input on how to best use the software and identify any potential challenges.

- Provide adequate training to employees on how to use the software. This will help them to get up to speed quickly and start using the software effectively.

- Monitor the implementation of the software and make adjustments as needed. It is also important to continuously look for new ways to improve your production processes.

- Use the software to generate reports and analytics. This data can help you to identify areas for improvement and track your progress over time.

Modern production software can be used to improve a wide range of production processes, including:

- Production planning and scheduling (APS): Modern production software can help businesses to optimise their production planning and scheduling by taking into account factors such as demand forecasting, inventory levels, and machine capacity. This can help businesses to reduce lead times, improve on-time delivery performance, and reduce costs.

- Manufacturing execution systems (MES): MES software provides real-time visibility into the production process, enabling businesses to track the progress of orders, identify bottlenecks, and make adjustments as needed. This can help businesses to improve efficiency, reduce waste, and improve quality.

- Quality management systems (QMS): QMS software helps businesses to manage their quality control processes, including inspections, testing, and corrective actions. This can help businesses to improve product quality and reduce the risk of recalls.

- Maintenance management systems (CMMS): CMMS software helps businesses to manage their maintenance activities, including preventive maintenance, predictive maintenance, and corrective maintenance. This can help businesses to reduce downtime and extend the life of their equipment.

- Warehouse management systems (WMS): WMS software helps businesses to manage their warehouse operations, including inventory tracking, order picking, and shipping. This can help businesses to improve efficiency and accuracy in their warehouse operations.

- Business intelligence (BI) and analytics: BI and analytics software can be used to generate reports and dashboards that provide insights into the production process. This data can be used to identify areas for improvement and track progress over time.

Specific examples of how modern production software can be used to improve production processes:

- A manufacturing company can use MES software to track the progress of orders in real time and identify any potential bottlenecks. This information can then be used to make adjustments to the production schedule and ensure that orders are completed on time.

- A food and beverage company can use QMS software to manage its quality control processes for its products. This includes tracking inspections, test results, and corrective actions. This information can be used to identify any quality issues early on and take steps to prevent them from occurring in the future.

- A clothing retailer can use WMS software to manage its inventory levels and order picking process. This can help the retailer to ensure that it has the right products in stock at the right time and that orders are picked and shipped accurately.

- A company that produces medical devices can use BI and analytics software to generate reports on its production process. This data can be used to identify areas where the process can be improved, such as reducing waste or improving machine utilization.

Conclustion

Production optimisation software is a powerful tool that can help businesses of all sizes to improve their operations. By effectively using this software, businesses can improve their efficiency, reduce costs, and improve quality.

Modern production software can be used to improve a wide range of production processes, including production planning and scheduling, manufacturing execution systems (MES), quality management systems (QMS), maintenance management systems (MMS), warehouse management systems (WMS), and business intelligence (BI) and analytics.

By using production optimisation software to track and analyze their production processes, businesses can identify areas for improvement and make necessary changes. This can lead to a number of benefits, such as reduced lead times, improved on-time delivery performance, reduced costs, improved product quality, and reduced downtime.

Overall, production optimisation software is a valuable tool for businesses that are looking to improve their operations and gain a competitive advantage.

Products in this Article

Manufacturing Operations Management System (MOM)

Manufacturing Operations Management System (MOM) The most complete manufacturing solution with full support for operations management and a link between industrial automation and business operations

Smart Machine

Smart machine A comprehensive solution for management, diagnostics, monitoring and control of the production line. Schedule a Demo They Trusted Us: Make sure you have

MES System – Manufacturing Execution System – ANT Solutions

System MES – Manufacturing Execution System 0 % operating time increase 0 % defects quantity reduction 0 % material consumption reduction 0 % changeovers time