The APS system is an advanced tool for planning production and responding to events occurring in real time. Integration of the software with other management systems in the factory allows changes in resource availability to be automatically detected and the plan to be optimised for efficient use. What does APS change in a modern factory?

What does production process planning look like using APS?

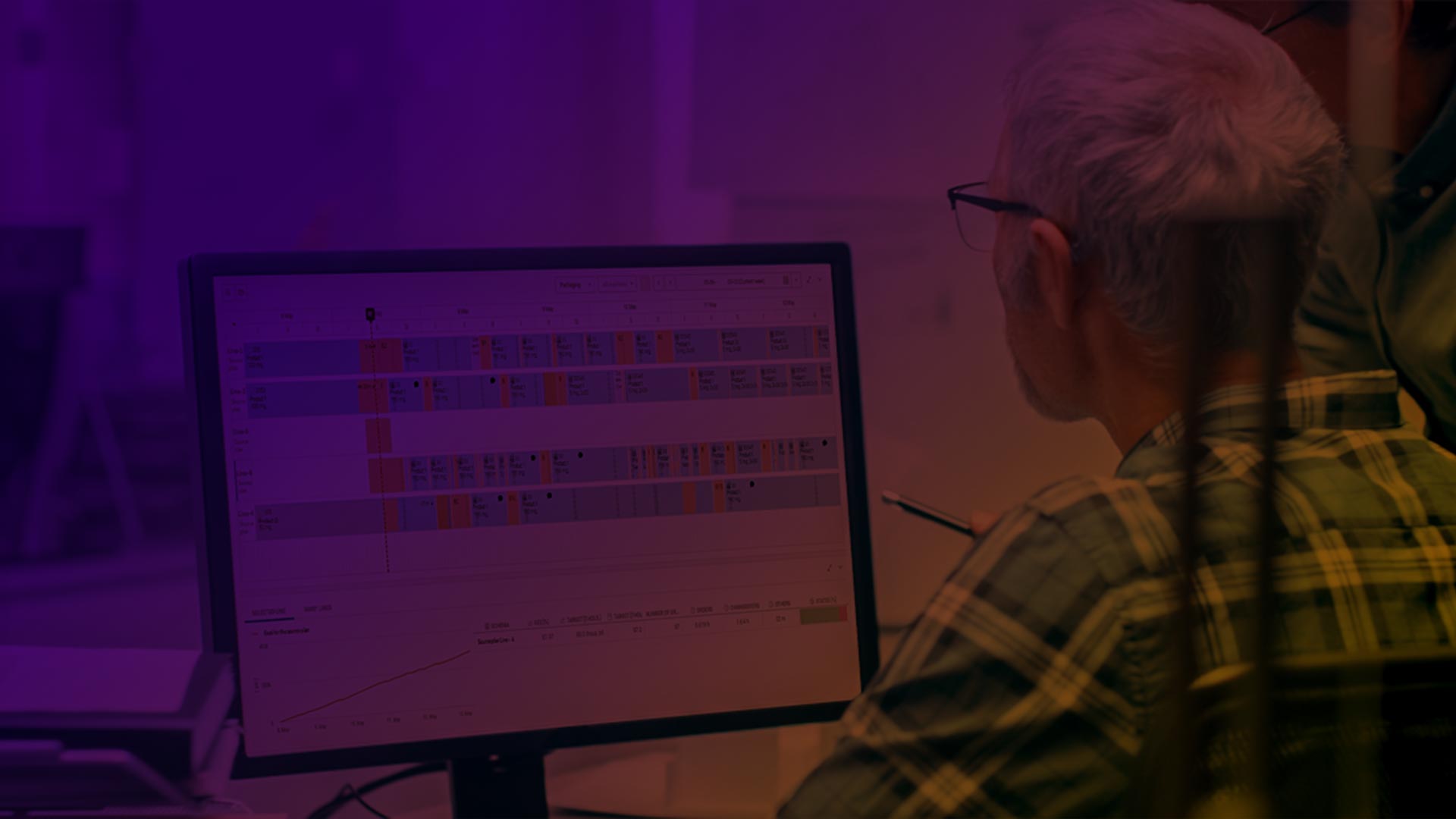

The APS system allows production overview and operation planning based on order information and available resources. The tool allows changes to be made automatically or manually. When integrated with a WMS, the software continuously monitors inventory data and adjusts the production plan on this basis.

The system not only gathers current information, but also takes into account historical data, which provides a reliable database of information regarding previous realisations. APS also makes it possible to plan changeovers or maintenance work so that, in the event of reduced machine availability, processes are spread over the remaining equipment in such a way as to achieve the highest possible productivity with the available resources.

The advantage of APS systems – real-time response to change

In order for the APS to maximise the availability of resources, it is necessary to integrate it with the other systems used in the industrial plant. The exchange of information between platforms allows real-time access to data on the status of machines or quantities of goods. In the event of unforeseen events such as an undelivered delivery or machine failure, the system automatically detects the anomaly and creates a new, updated schedule based on current information. An example of such a system is ANT APS, which uses artificial intelligence to automatically recalculate data and predict future operations, thus helping to create realistic production plans. It is the ability to take a rapid response in response to real-time data that is the competitive advantage of a system for advanced planning and scheduling.

Why use the APS system?

Modern factories using the APS are seeing higher production volumes. The software significantly reduces changeover times and the number of changeovers. The real-time response makes it possible to instantly adapt the plan to the current state of resources, making production more predictable. An additional benefit of using a modern system is the automation of correct decisions in the event of sudden changes – the re-scheduling of production and its adjustment to the current capacity of the plant is carried out reliably and reliably.

Related to this article

MES & APS. A cloud project takeoff with Quadpack

Quadpack, a leading manufacturer of packaging solutions, has decided to implement a new production system from ANT Solutions, a renowned provider of production management solutions.

Advanced Planning and Scheduling (APS)

AdvancedPlanning & Scheduling (APS) Planning and scheduling production is made more accessible with ANT’s APS software. Maintain a constant production pace with the help of