Manufacturers operating in the automotive industry are currently facing a major challenge – maintaining competitiveness while mitigating the environmental impact of production processes requires them to use modern, advanced technological solutions. In the era of Industry 4.0, how can sustainable production and high quality standards be maintained?

Key challenges in the automotive sector

The automotive industry deals with the production of cars and is one of the most important industries. Characteristic of automotive is unit and small batch production. In this case, the most important indicator is the quality of the products, on which the efficiency and safety of the cars leaving the production line depend. Processes and the quality of individual components and finished vehicles must comply with the stringent standards in force.

Opportunities and challenges in the automotive industry.

Industry reports are under no illusion: the pandemic crisis, the problem of maintaining a continuous supply chain, limited access to raw materials and rising raw material and energy costs, and last but not least, weakened consumer interest, have caused companies that were not prepared for such a scenario to face major problems. Electric vehicles, on the other hand, are enjoying a good run, with a steady increase in sales. Companies with a competitive market position continue to face the challenge of cost optimisation. In the automotive industry, there is no room for mistakes or wasted raw materials, as recent events have shown.

Restrictions on environmentally friendly measures imposed by governmental bodies are also a challenge for car manufacturers. The EU’s plan is to ban the sale of internal combustion cars from 2035, meaning that only vehicles with electric, hydrogen or other zero-emission propulsion will leave production lines in future. According to media reports, a revision of this regulation is planned for 2026, but regardless of the outcome, manufacturers must show flexibility and be prepared for changing trends.

Production in the automotive industry with an MES system – bet on the highest quality!

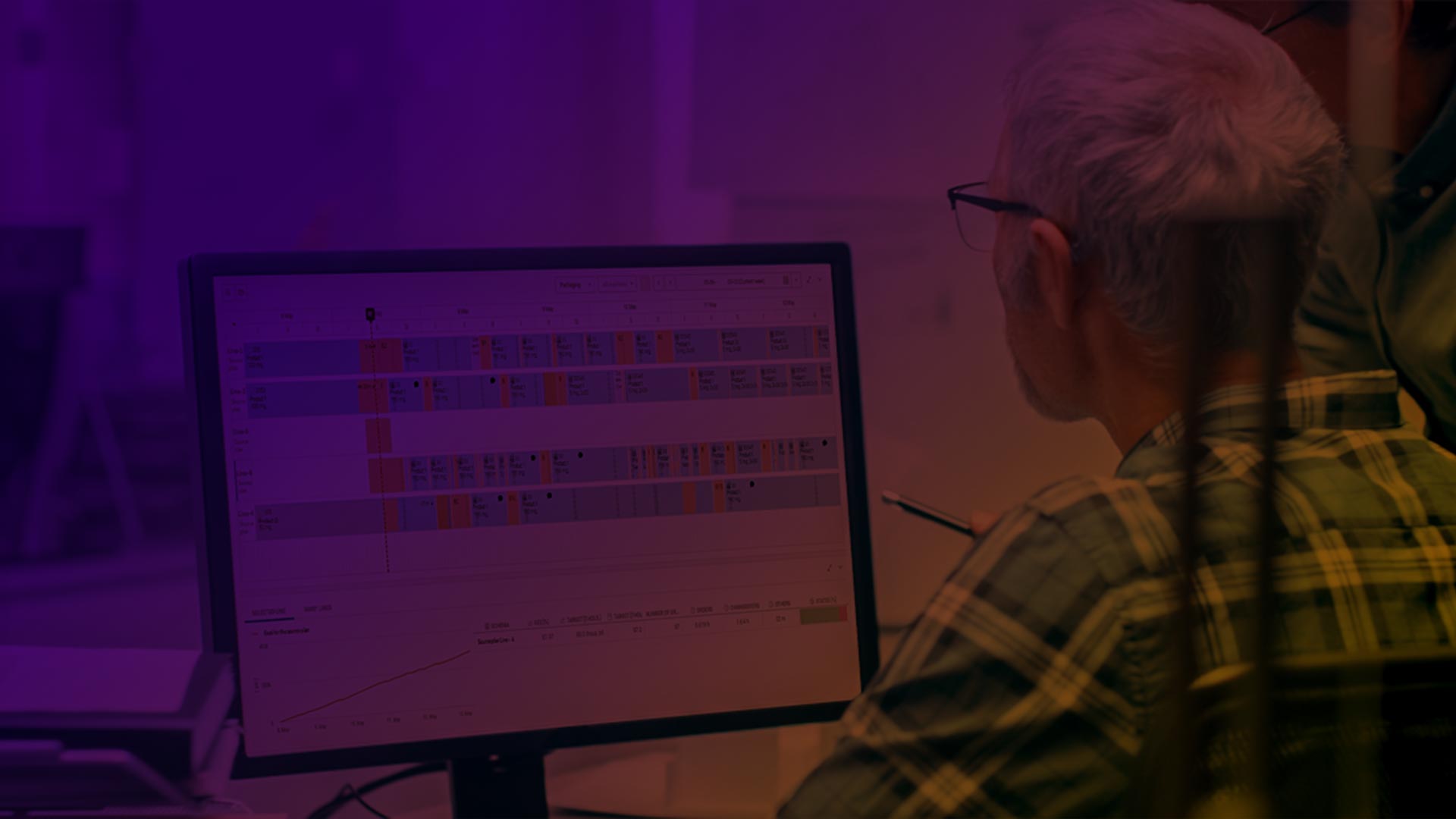

ANT MES for Automotive is a solution that guarantees high production quality while reducing production costs. The software is suitable for discrete and small batch production. In the case of the automotive industry, an important aspect of production is the quality of the processes and the final product. With MES, we can guarantee that all products leaving the production line meet the specified standards.

ANT solution supports highly complex production and enables efficient management of operations such as metalworking, marking, assembly, packaging, batching and more. The ANT software enables the tracking of raw materials, components and tools used, along with their validation, and guides the operator through multi-operation production on an automated line. Real-time algorithms monitor whether the machine’s process parameters and operator measurements are within set standards.

MES in vehicle manufacturing – 5 key benefits

The MES system is a state-of-the-art solution readily used by leaders operating in the automotive industry. What benefits can the use of this software bring to your factory?

-

- Strict quality control – tracking and validating process parameters, as well as the raw materials and components used, allows real-time control of the correct course of operations. The result: production in line with standards.

-

- Timely production and improved efficiency – thanks to the Real-Time Scheduler and its advanced algorithms, we can react quickly to breakdowns and change the production plan to match current capabilities. The result: finished products leave the line on schedule.

-

- Reduced production costs – information on errors and failures reduces defects and scrap, and makes efficient use of raw materials and resources. The result: higher machine availability and reduced production costs.

-

- Flexible production – system support for multiple operations works well for both conventional and zero-emission vehicle production. The result: preparation for changing trends in the automotive industry.

-

- Eco-friendly production – efficient production translates into a reduced carbon footprint per unit of product. The result: higher competitiveness of the company and compliance with further government restrictions on environmentally friendly production.

No one doubts any longer that in order to keep up with Industry 4.0 and prepare for the challenges that Industry 5.0 brings, the use of software such as MES for Automotive is becoming a necessity. Supporting processes with a comprehensive production management platform makes it possible to manage resources sensibly, reduce unnecessary costs and, above all, keep the company competitive.

Products in this Article

CMMS System for Maintenance Management

Computerized Maintenance Management System (CMMS) Plan, manage and react with CMMS System by ANT. The best maintenance system for equipment performance in your factory. It

MES System – Manufacturing Execution System – ANT Solutions

System MES – Manufacturing Execution System 0 % operating time increase 0 % defects quantity reduction 0 % material consumption reduction 0 % changeovers time

Advanced Planning and Scheduling (APS)

AdvancedPlanning & Scheduling (APS) Planning and scheduling production is made more accessible with ANT’s APS software. Maintain a constant production pace with the help of