AI in manufacturing

Be ready to implement your AI tools in factory thanks to "push interface" and data preparation.

- The Growing Role of AI in Industry: Manufacturers, initially slow to adopt digital technologies, are now recognising AI’s potential in reducing costs, increasing efficiency, and improving products.

- AI as a Board-Level Priority: The emergence of tools like ChatGPT has elevated AI to a priority for manufacturing executives. Consulting firms like EY report a surge in enquiries from manufacturing clients about AI implementation.

- AI Strategy Linked to Business Goals: Experts recommend aligning AI implementation strategies with a company’s overall digital and business strategies, ensuring each use case has clear business justification.

- Be Ready for AI.

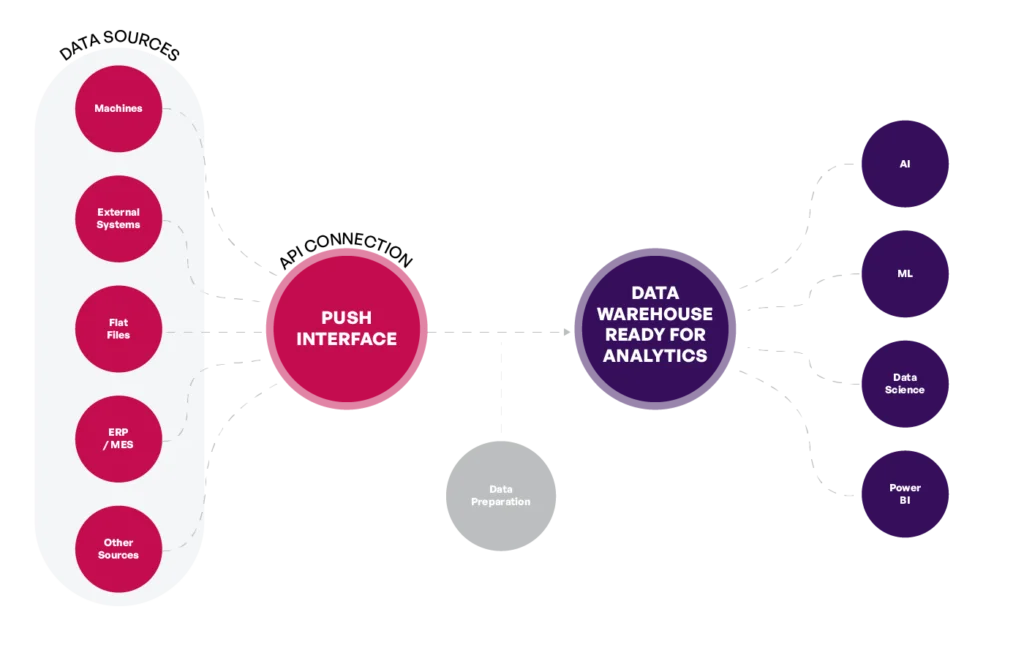

A push interface from ANT Solutions is crucial for providing real-time data to AI services. To maximize the potential of AI in industry, it’s vital to focus on efficient data collection, preparation, and storage in industrial systems.

Artificial Intelligence (AI) and Machine Learning (ML) - Definitions and Differences

AI (Artificial Intelligence) is a broad concept that describes systems designed to perform tasks without explicit programming instructions. This means that instead of programming AI step by step, frameworks are created that allow it to learn on its own based on input data and feedback. The goal of AI is to create models that can solve problems and make decisions similarly to humans.

Generative AI (GenAI) is a specialized branch of AI focused on creating new content, such as text, images, audio, and more, based on the data it has been trained on. Unlike traditional AI, which may focus on analyzing or predicting data, Generative AI actively produces original outputs that can mimic human creativity. Examples of GenAI include language models like GPT, image generators like DALL-E, and music composition tools. The primary objective of GenAI is to generate content that is not only coherent and contextually relevant but also innovative and creative. GenAI is based on Large Language Model (LLM) algorithmic technic.

ML (Machine Learning) is a subset of AI that focuses on algorithms that learn from input data and feedback to improve their performance. In ML, these algorithms receive input data and feedback, then adjust their parameters (weights and biases) to become better at performing a given task.

Difference between AI and ML:

Scope

AI is a broader concept that encompasses various techniques, including ML and GenAI. GenAI is a specialized AI that concentrates on generating new content.

Method of Operation

AI can operate based on different principles, whereas ML focuses on algorithms that learn from data. GenAI employs advanced ML techniques, such as deep learning, to create novel content based on learned data patterns.

Goal

AI and GenAI aims to create systems that mimic human intelligence and creativity, while ML concentrates on developing systems that learn and improve their performance based on data.

Generative AI is transforming the manufacturing industry, offering innovative solutions to longstanding challenges. With a projected $10.5 billion in added revenue by 2033, its impact is set to be both substantial and far-reaching.

Key applications include rapid identification of production issues, faster creation of work instructions, and enhanced coding capabilities for staff. According to McKinsey, GenAI’s potential extends to optimising planning, improving efficiency through predictive root cause analysis, and streamlining delivery with AI-powered customer communication. When combined with technologies like digital twins, GenAI can accelerate warehouse design and production scenarios.

While still in its early stages, the manufacturing sector is steadily adopting AI-driven tools, particularly in back-end operations, as they prove their value in boosting efficiency and supporting digital transformation.

Scaling Traditional Machine Learning

Traditional ML models like machine vision and graph-based natural language processing are scaling up. As ROI from AI tools grows, technologies mature, and digital transformation strategies accelerate, these models are increasingly deployed across back-end and operational use cases.

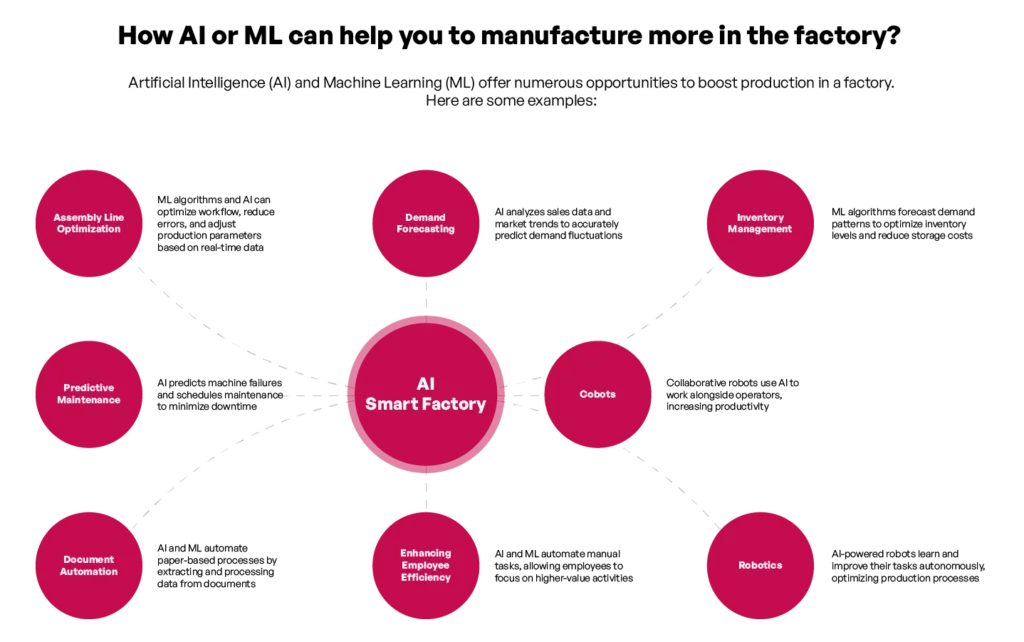

AI and ML in the Factory: Increasing Production

Artificial Intelligence (AI) and Machine Learning (ML) offer numerous opportunities to boost production in a factory. Here are some examples:

Assembly Line Optimization

- ML algorithms can analyze historical data and real-time sensor data to optimize workflow on the assembly line.

- AI can identify and correct errors, as well as predict potential failures.

- Intelligent automation allows adjusting production parameters to demand fluctuations, reducing waste and optimizing resource utilization.

Example: Volkswagen uses AI-based solutions to optimize assembly lines, increasing production efficiency and quality.

Demand Forecasting

- AI analyzes historical sales data, market trends, and external factors to accurately predict demand fluctuations.

- This allows manufacturers to adjust production, minimizing the risk of stockouts or excess inventory.

Example: A clothing manufacturer can use AI to analyze social media trends, weather forecasts, and customer preferences to accurately predict demand for various products.

Inventory Management

- ML algorithms analyze historical data, current inventory levels, and market trends to accurately forecast demand patterns.

- This enables optimizing inventory levels, reducing storage costs, and ensuring product availability.

Example: An automotive parts manufacturer can use ML models to forecast demand for spare parts, allowing them to optimize inventory levels and reduce costs.

Predictive Maintenance

- AI analyzes data from sensors and machines to predict failures and establish optimal maintenance schedules.

- This helps minimize downtime and ensures the availability of resources and spare parts for quick repairs.

Example: Companies like Pepsi and Colgate use technology developed by the startup Augury to detect issues with production machines before they lead to failures.

Cobots (Agents)

- Collaborative robots (cobots) increase productivity by working alongside operators.

- They use AI for navigation and object identification in order fulfillment centers, streamlining picking and packing processes.

- GenAI can be used to summarize daily tasks for operators.

Example: Amazon’s cobots use ML to accelerate order fulfillment and improve logistics.

Document Automation

- AI and ML are used to automate paper-based processes such as purchase orders, invoices, and quality control reports.

- Intelligent bots with GenAI capabilities can automatically extract data from documents, classify and categorize information, and then enter it into appropriate systems.

Example: Whirlpool uses RPA to automate production processes, including tasks on the assembly line and material handling.

Enhancing Employee Efficiency

- AI and ML can automate many manual tasks, freeing employees from tedious work and allowing them to focus on higher-value tasks.

- AI tools can help employees find needed information faster and more easily, analyze data, and make decisions.

Example: AI can support financial planning, demand planning, and MRP planning processes, reducing the risk of human errors and increasing efficiency.

Robotics

- Production robots, using AI, can learn and improve their tasks without the need to program each step.

- They independently identify problems and optimize production processes.

Example: AI-powered welding robots analyze welding points and adjust their actions to improve quality.

AI and ML offer numerous opportunities to increase production in a factory. From optimizing processes to automating tasks and enhancing human work, these technologies can bring significant benefits to manufacturers.

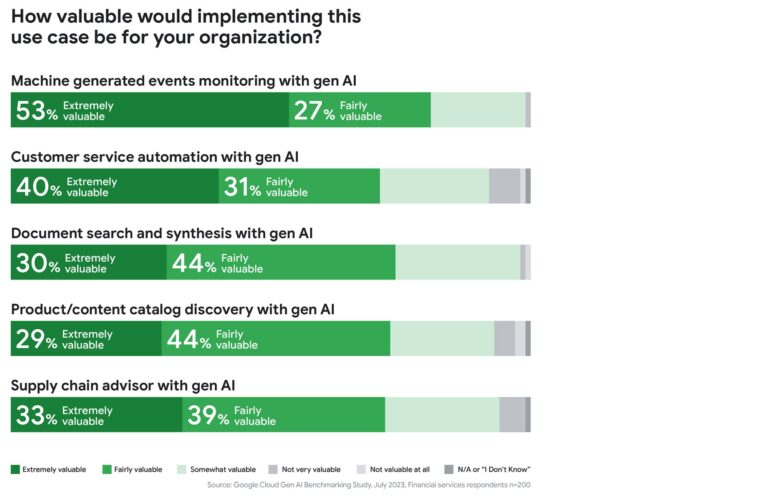

Five GenAI Use Cases from Google

Generative AI is revolutionising the manufacturing industry, addressing challenges like labour shortages and supply chain disruptions. Google highlights five key applications: monitoring machine events, automating customer service, streamlining document searches and synthesis, enhancing product catalogue searches, and optimising supply chain operations. These use cases showcase how GenAI can boost efficiency and transform industrial processes.

Challenges in AI Implementation in Industry

-

- Data Quality: Like in any sector, better data management is crucial to power AI and empower teams. AI requires terabytes of data from diverse sources, including enterprise systems, machine sensors, connectivity infrastructure, and human operators. Leading companies in AI adoption invest in building robust data foundations, giving them a competitive edge.

-

- Operational Risks: Reece Hayden of ABI Research highlights operational risks as the biggest challenge for AI in industry, especially generative AI. Manufacturing operations are mission-critical, demanding accuracy, reliability, safety, privacy, availability, and low latency. Generative AI models are still immature, generalised, and limited in accuracy, making them unsuitable for many applications. Their size and memory demands also make edge deployment challenging, though Hayden predicts eventual scaling of GenAI for edge applications.

Be Ready for AI – Time to prepare you data.

AI/ML systems are much less efficient when, or in some cases, they can’t read unstructured data that is uploaded to the system. Therefore, many companies first do data cleansing and preparation to fetch them into data warehouses. Huge databases where all the data is sorted out and made readable for machine learning algorithms. How to do it in the first place?

"Push Interface" for Data and AI in Industry

A “push interface” that enables data transmission to selected AI services is a system that actively sends data to AI-based services instead of waiting for requests from those services.

For example, a machine monitoring system in a factory. Sensors on machines collect operational data, and the push interface automatically transmits this data to an AI platform. The AI analyses it in real time to detect potential failures and prevent downtime.

Data Acquisition, Preparation, and Warehousing in the AI Context

In manufacturing and AI applications, the processes of data acquisition, preparation, and storage are crucial for success. These steps are described as follows:

1. Data Acquisition:

- Diverse Sources: Factory data comes from various sources, such as machines, sensors, ERP systems, PLM, and quality control systems.

- System Integration: Connecting these systems is necessary to gain a comprehensive view of operations.

- Integration Methods: Common methods include ETL (Extract, Transform, Load), ELT (Extract, Load, Transform), data virtualisation, and CDC (Change Data Capture).

2. Data Preparation:

- Raw Data: Data collected from various sources is often raw and unstructured.

- Preparation Stages: The preparation process involves data quality assessment, cleaning, enrichment, and transformation.

- Data Cleaning: Removing errors, standardising formats, and eliminating duplicates.

- Data Enrichment: Adding contextual information to enhance data value.

- Data Transformation: Converting data into a format suitable for analysis, such as aggregation, normalisation, and creating new variables.

3. Data Warehousing:

- Central Repository: A data warehouse serves as a centralised storage location for structured production data, such as production metrics, equipment performance, and inventory levels.

- Cloud Solutions: Cloud-based solutions like Snowflake are popular, offering scalability and flexibility for managing large datasets.

- Data Lake: Often, data is first gathered in a “data lake,” where it undergoes initial preparation before being moved to a data warehouse.

Read how to manage your data steams to use it with AI tools with series of articles on Enterprise Data Platform. Manufacturing Data Analytics – Unlocking Insights with an Enterprise Data Platform

The bottom line

AI holds immense potential to transform industry, offering benefits like increased efficiency, better product quality, and more effective supply chain management. However, challenges such as ensuring data quality and managing operational risks remain significant. Despite these hurdles, AI is a crucial technology for the future of manufacturing, and early adopters stand to gain a significant competitive advantage.

Be ready before you implement AI in you factory. A push interface plays a key role in delivering real-time data to AI services. To fully leverage AI in industry, effective data acquisition, preparation, and storage are essential.

Data warehouses and data lakes are vital components of an enterprise’s data infrastructure, and their importance will grow alongside the development of AI applications in manufacturing.

Talk about AI

Contact with our Expert

Get more insights

Manufacturing Data Analytics – Unlocking Insights with an Enterprise Data Platform

Manufacturing Data Analytics: Unlocking Insights with an Enterprise Data Platform Manufacturing is undergoing a digital transformation, fueled by the vast amounts of data generated across

Data warehouse vs data lake, what are the differences?

Data Lakes and Data Warehouses: Cornerstones of Modern Manufacturing The manufacturing industry is undergoing a data revolution. With advancements in technology, factories are generating unprecedented

Methods of Data Integration and Preparation in a Factory Setting

Data is the key In the manufacturing sector, data is generated from a multitude of sources, including production equipment, sensors, ERP systems, and quality control