La guida dell'operatore è una parte essenziale del processo di produzione. In primo luogo garantisce che il processo venga eseguito seguendo le linee guida tecnologiche sviluppate. Il supporto passo-passo dell'operatore elimina anche la necessità di manipolare ulteriormente i parametri e garantisce che nessuna fase di produzione venga trascurata.

Il supporto al controllo da parte dei sistemi di classe MES consente di ricordare i controlli necessari e di indicare se il risultato è stato raggiunto. entro i limiti di qualità senza la necessità di interpretare i risultati da parte di chi esegue il controllo. I moderni software consentono inoltre di velocizzare i cambi di produzione e l'avvio della produzione e facilitano notevolmente l'inserimento dei nuovi assunti. In che modo i sistemi di gestione della produzione consentono di guidare l'operatore e perché vale la pena implementare una soluzione di questo tipo?

Guida automatica dell'operatore durante i cambi di produzione e altre attività

Il tempo è fondamentale in officina. Le fabbriche moderne, quindi, si sforzano di utilizzare ogni secondo in modo produttivo e ridurre al minimo i tempi di inattività. Uno degli elementi che hanno un impatto positivo sui risultati di disponibilità è la riduzione dei tempi di cambio macchina.

Alcuni tipi di produzione (ad esempio, farmaceutica e alimentare) comportano modifiche complesse e lunghe di impostazioni e parametri. Gli standard di qualità previsti richiedono agli operatori di seguire procedure rigorose in centinaia di documenti. Come si può conciliare tutto questo?

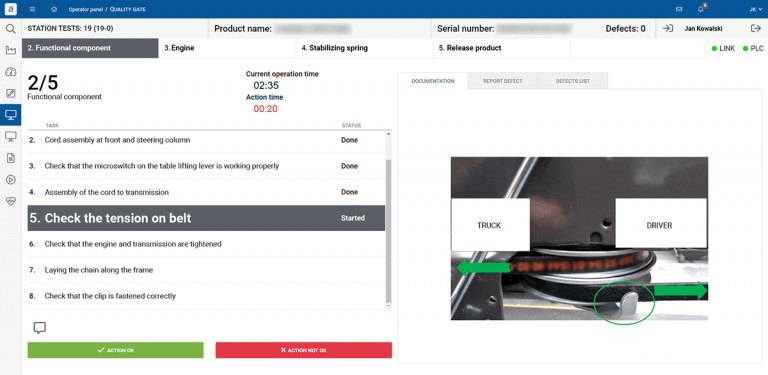

Software di produzione dedicato aiuta in guida per l'operatore attraverso il processo di produzione. ANT Solutions è una soluzione completa che si concentra sull'automazione di tutte le attività possibili. L'operatore non deve cercare le informazioni necessarie, poiché tutti i dettagli sono visualizzati sul pannello operatore. La guida per l'operatore quasi conduce gli operatori a manoPerciò non perdono tempo a chiedersi cosa fare in una determinata situazione. Al contrario, agiscono immediatamente in base alle aspettative stabilite, utilizzando in modo efficiente tutto il loro tempo di lavoro.

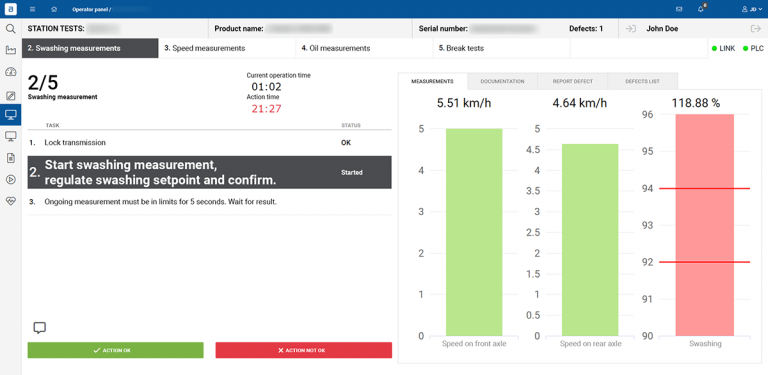

Inoltre, un sistema avanzato indica la necessità di controllare la qualità dei componenti prodotti. Controlli regolari facilitano il raggiungimento di risultati soddisfacenti ed evitano rilavorazioni dovute a parametri inseriti in modo errato o a un errore trascurato da un dipendente.

Guida per l'operatore: la via per una produzione efficiente

In che modo un software avanzato migliora l'efficienza della produzione? Un sistema all'avanguardia guida l'operatore in tutte le fasi: dall'avvio della macchina, al controllo degli utensili e delle materie prime, fino alla ricezione del prodotto finito.

La guida per l'operatore fornisce un supporto completo per l'operatore durante il cambio macchina e facilita l'utilizzo della macchina. standardizzazione e ottimizzazione dei tempi di produzione. Istruzioni chiare garantiscono che nessun passaggio venga trascurato.

L'operatore riceve le istruzioni sullo schermo. Queste possono essere File PDF, immagini o video. Non è necessario analizzare documenti complessi: la forma semplice di comunicazione consente un rapido onboarding dei nuovi assunti e rende il lavoro del personale esperto molto più gestibile.

Soprattutto, il sistema MES facilita il monitoraggio in tempo reale della produzione, consentendo l'immediata individuazione dei difetti, la rapida introduzione di modifiche e l'aggiornamento delle attività in modo che il lavoro possa essere completato in tempo.

Con la guida digitale si ottiene uno strumento potente. Può ricordare all'operatore le attività da svolgere in un determinato momento. Inoltre, può anche informare sulle attività da eseguire dopo la produzione di un certo numero di pezzi o ricordare le attività da eseguire dopo un guasto entro un certo periodo di tempo. Il sistema può anche invia una notifica quando è necessario preparare i campioni o eseguire un controllo di qualità a causa del superamento dei valori limite.

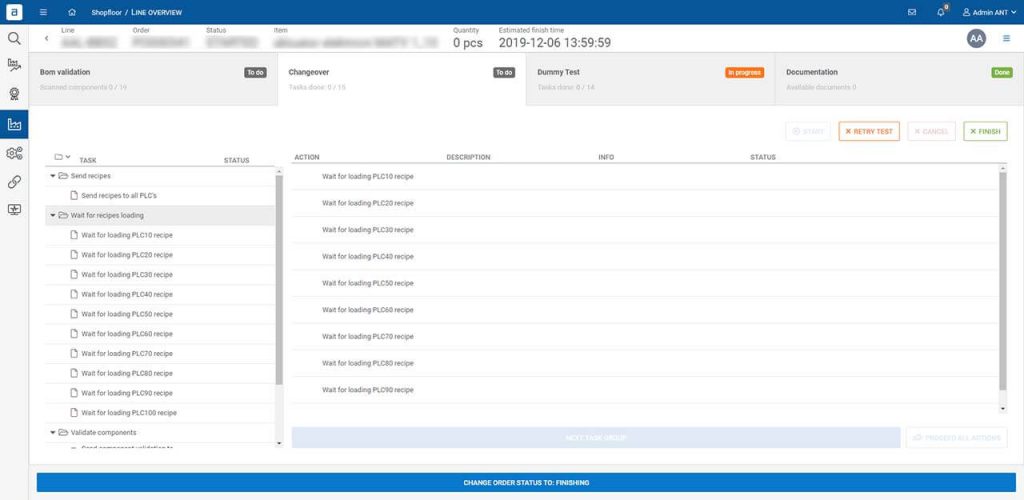

Guida rapida dell'operatore ai cambi di formato - caratteristiche principali

In che modo il software guida l'operatore nel processo di produzione? Una caratteristica importante è la matrice di cambio formato, uno strumento utile per il cambio macchina. Essa aiuta a definire quali azioni esatte sono necessarie per cambiare tipo di produzione. Il cambio di produzione da un articolo A a un articolo B può richiedere fasi diverse rispetto a quelle necessarie per passare da un articolo A a un articolo C. Matrice di cambio formato aiuta a calcolare il tempo e a visualizzare i passi da compiere e gli strumenti da cambiare per avviare nuovi elementi. Suggerisce inoltre quali strumenti devono essere modificati per avviare il processo successivo.

Un'altra caratteristica essenziale del software automatizzato è la creazione della produzione. linea centrale e le linee di comando superiore e inferiore. Questi indicatori consentono le stesse impostazioni indipendentemente dall'operatore che controlla la macchina. Ogni indicatore ha gli stessi parametri, il che garantisce una produzione ripetibile. Inoltre, la suddivisione del cambio formato in compiti che devono essere svolti da personale competente (tecnico, operatore, controllo qualità) evita un processo incontrollato.

La segnalazione automatica delle azioni successive è possibile inviando segnali alla macchina per avviare un'attività, come versare una certa quantità di olio o regolare la velocità in base ai limiti attuali.

Perché utilizzare un software per la produzione?

L'utilizzo di un sistema di gestione della produzione consente di automatizzare la maggior parte dei processi. Raccogliendo dati in tempo reale e comunicando online con l'operatore, è possibile ridurre i tempi di risposta fino a 65% rispetto ai metodi standard. Il rilevamento rapido delle irregolarità consente di ridurre i problemi di qualità, il che si traduce in un aumento significativo del valore OEE. I dati vengono acquisiti nel sistema e le istruzioni e le linee guida vengono visualizzate sui monitor, riducendo i tempi di trasferimento delle informazioni ed eliminando la necessità di rapporti cartacei.

La connettività delle macchine garantisce processi ripetibili, standardizzando e ottimizzando le operazioni di produzione.

Quali sono i vantaggi del moderno controllo dell'officina?

Uno dei vantaggi più importanti della guida dell'operatore è quello di essere sicuri che i processi tecnologici si sono svolti come previstoutilizzando un software moderno in officina. Una guida chiara e rapida per l'operatore assicura che nessuna fase del processo produttivo venga trascurata. Questa funzionalità ha l'ulteriore importante vantaggio di sollevare l'utente dall'incombenza di pensare al compito da svolgere, riducendo in modo significativo i tempi di produzione e ottenendo risultati migliori.

Il sistema consente inoltre di misurare e confrontare il tempo necessario per completare un determinato compito e di utilizzare questi dati per ottimizzare i tempi di cambio.

Il monitoraggio della produzione in tempo reale consente di individuare rapidamente i potenziali rischi e di prevenirli. L'immediata rilevamento dei difetti consente di eliminare i fattori che causano i difetti, garantendo così prodotti di alta qualità. L'aggiornamento delle attività sulla base dei dati attuali facilita una pianificazione della produzione più accurata e un completamento tempestivo.

La raccolta dei dati in tempo reale attiva anche la segnalazione automatica delle attività di manutenzione in produzione, contribuendo a mantenere l'operatività, a garantire la continuità e a utilizzare nel modo più efficiente il tempo degli operatori delle macchine.

Ulteriori letture

Come ottimizzare il piano di produzione?

Oggi la pianificazione della produzione richiede una particolare precisione, operando in tempo reale e aggiornando gli obiettivi in relazione allo stato attuale delle macchine. Solo su questo

Pianificazione e programmazione avanzata (APS)

AdvancedPlanning & Scheduling (APS) La pianificazione e la programmazione della produzione sono rese più accessibili con il software APS di ANT. Mantenete un ritmo di produzione costante con l'aiuto di

Controllo macchina

Machinecontrol Assumete il pieno controllo del vostro parco macchine Machine Supervision System - rendete la produzione più efficace, automaticamente! Il controllo dei processi produttivi è necessario per garantire una produzione di alta qualità.