Overall Equipment Effectiveness (OEE) is a commonly used indicator in manufacturing plants. It allows to determine how efficient is a given production line, and thus how efficient the production is in relation to its production capabilities. The index is the result of three factors to measure the performance of a production line:

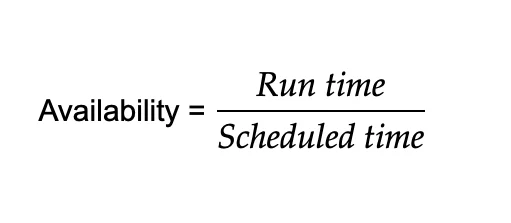

Availability = actual machine running time / scheduled time

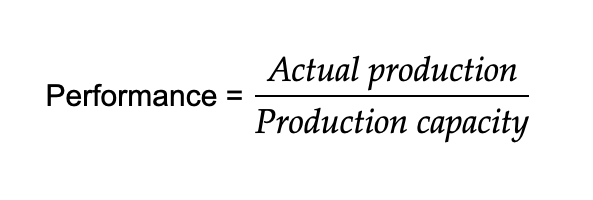

Productivity (actual production time / production capacity)

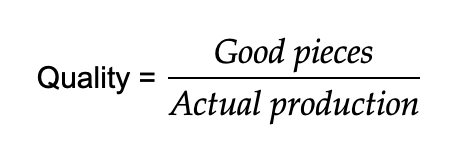

Qualità (number of pieces properly produced / total production)

Nell'industria manifatturiera, l'enfasi è posta sul raggiungimento di prestazioni ottimali in tutte e tre le aree, che sono fondamentali per il successo del funzionamento della linea, poiché ogni area contribuisce singolarmente alla redditività di un prodotto o di un servizio e alla redditività.

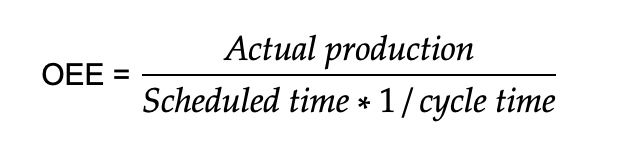

OEE può anche essere rappresentato come la produzione effettiva divisa al denominatore in tempo programmato moltiplicato per un ciclo di produzione, come mostrato nella formula seguente:

Ultimately, OEE is influenced by many factors that depend on the overall operation of the factory. Among the events that have an impact are

- Unplanned downtime

- Failures and repair times MTTR, MTBR, MTTF

- Slow start-up of production

- Late recognition that a process is unstable

Read more about OEE in the article “12 reasons why OEE is low”.

Calculate your OEE in no time with our OEE calculator.