Tobacco

senza carta

Sistema

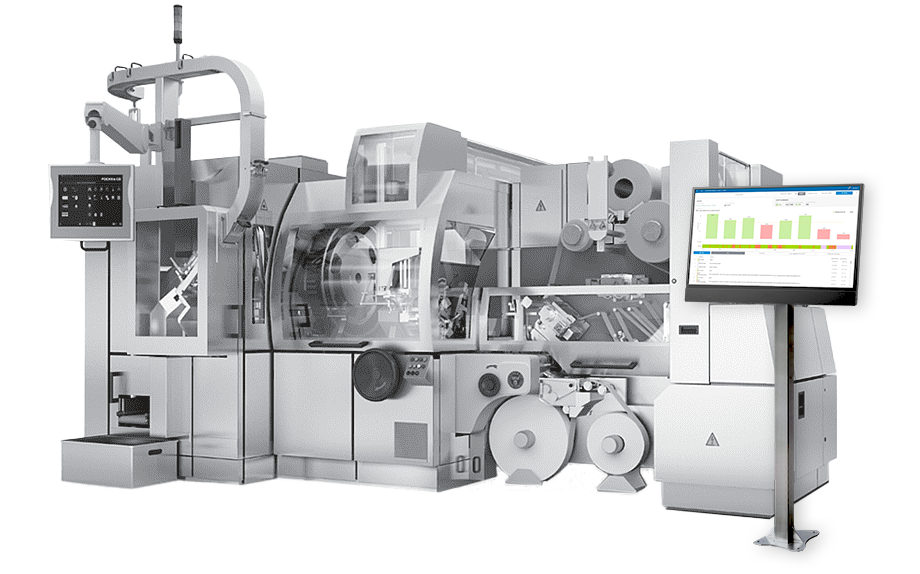

Our Tobacco Manufacturing System aims at increasing the efficiency of production through raise of the awareness about machines’ work with real-time, accurate information

The system consists of software and hardware components that monitor the entire tobacco products manufacturing processes on an ongoing basis and provides full visibility of the production. Complete transparency of the factory within its employees, who can see the actual real-time effects of their actions, results in their increased active involvement in improvement of processes, minimization of most commonly occurring stoppages and significant increase in overall efficiency of the equipment and entire factory. Increase manufacturing volume of cigarettes, filters and modern oral products.

Proven solution

| Pain points | Soluzione | Vantaggi |

| Common line micro-stops. | Detection of all stops of machines with core reasons, statistics and analysis. | Increase OEE. |

| Lack of knowledge about production at any point of time. | Real-time data acquisition and calculation of KPIs, transparent factory. | Informed decision making. |

| Paper reports. | Digital dashboard and reports. OEE loss tree, drill-down analysis, dedicated reports, factories comparison. | Full visibility. |

| Common machine failures | Reporting and handling failures and predictive maintenance. CMMS and ANDON addon. | Increase MTBF. |

| Missed deadline, low production volume | SFT Integration. Production progress reporting. | Faster time to market delivery. |

ANT has made huge progress all around the world. I’ve not heard any negative feedback from anyone about your services, so that’s a good achievement in itself.

Martin John

Global Category Manager – Production

I have been with some senior members in the business yesterday and I must share that they are highly impressed with the operator visibility and solution as a whole. Well done guys!!!

Vikash Harkinson

Operations Management

Just wanted to say thank you for the great work that you did during phase 1 installation. I wish more contractor would raise to this level of professionalism.

Vlad Homorozeanu

TaO Stabilization Lead

Tobacco Suite Standard – general specification

ANT Tobacco Suite aims mainly at increasing the efficiency of production through raising the awareness of machines’ work with real-time, accurate information supplemented by machine Operator’s input.

System has been designed to fully support IWS methodology and is constantly improved in that direction – it follows the processes, gathers the right data and presents it in a way that allows Business and Production to take conscious actions.

Thanks to the dedicated panels and advanced Operator Panel, the whole factory can have full visibility of production and machines’ states, which results in growing shared responsibility to increase the efficiency of the whole site.

System itself is divided into several modules for easy navigation and can be further developed by implementing ready “Addons” that add next functionalities and enhance the existing system.

Tobacco Suite Standard – Covered Technologies

Tobacco Suite system is already covering most of the technologies that can be met on a production floor, both in terms of processes and equipment.

The suite is present on the following departments:

SMD (Regular, LCO):

- Maker

- VE

- SE

- MAX

- Buffer

- Imballatore

- Cello

- Stamper

- Bundler

- Case Packer

FMD:

- Filter Makers

- AF

- KDF

- HCF

- Unloader

- Filter Shooters

- Magomat

- Taurus

OTP:

- Products:

- Snus (oral)

- Lyft (oral)

- Pouches

- Cans

- Machines

- Weighers

- Maker

- Imballatore

- Djura

- Foil wrapper

- Bundle Machine

- Checkweighers

- Conveyer systems

- Case Packer

WHY US?

No macchina upgrades necessario

No disruption to the production: 10-60 min per macchina necessario

100% URS covered by ANT standard system

Tobacco know-how (dedicated, experienced team, Integrated Works System best practices)

Fast ROI – Return of Investment

Presentazione del sistema

Contatto con il nostro esperto

Perché ottenere una demo?

- Incontro online di 60 minutiti con uno specialista dedicato che presenta un sistema top di un settore simile

- Modellazione dal vivo del vostro processo produttivo

- Preventivo dopo l'incontro