ANT Add-Ons

The main products like OEE Performance Monitoring, MES or PDMS is just the beginning.

To squeeze even more from your production and place your factory on another level, we need to talk about ANT add-ons.

Paperless Production – eliminate paper and paperwork from your production with modern digital tools and forms.

Real-Time Scheduling – improve accuracy planning with optimisation algorithms and make it more reliable by using real cycle time and history learning.

微停机监测 – locate bottlenecks, measure precise micro-stops time and find the root cause for slow cycles and production line stops.

机器控制 – automatically upload programs, recipes and set-points to your machines and reduce production launching time.

互动会议 – improve your daily production meetings by replacing whiteboards with interactive, digital touchscreens

Examples of Add-Ons for smart factories

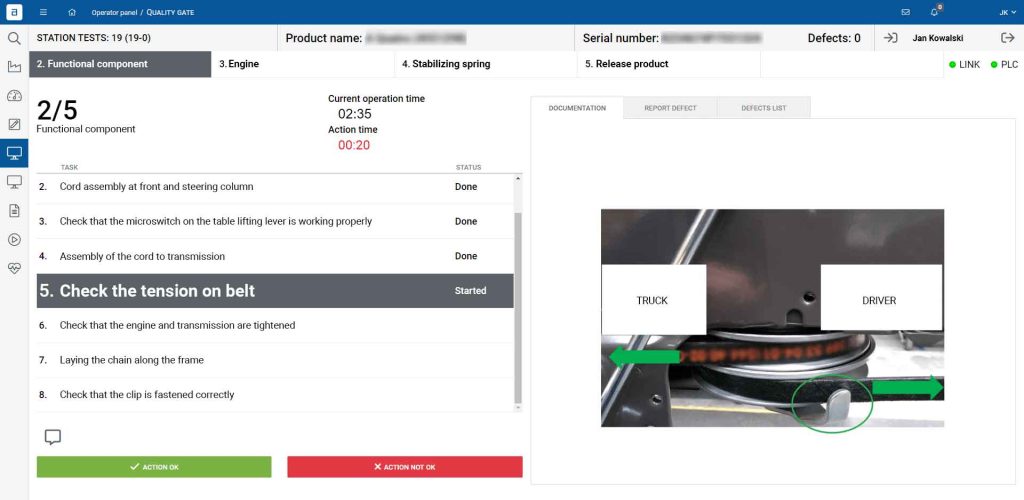

Paperless production

Features:

- Replace all paper documents, forms, instructions with the digital version by using the drag&drop tool

- Display step by step activities 至 guide the operator through 生产 和 交接

- Fill the data automatically in the forms based on data from machines and production order

效益:

- Save time and money thanks to paper and paperwork elimination

- Ensure that the production process was executed with planned, standardised technology

- Reduce human errors and increase production repeatability

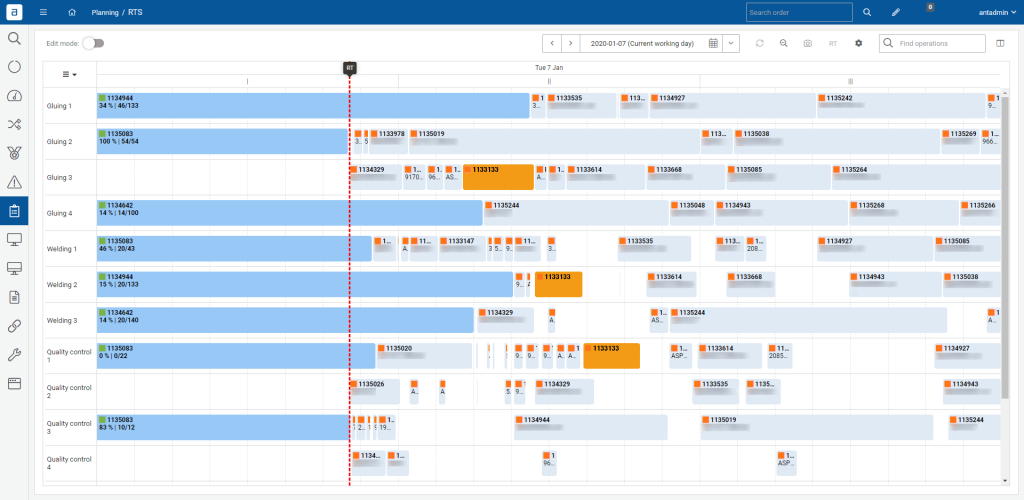

Real-Time Scheduling

Features:

- Plan your production base on the product’s real cycle time to make it more reliable

- Optimise plan by the algorithm that selects the best possible sequence, machines and resources

- Drag&drop production orders on the Gantt timeline

效益:

- Get a more accurate plan thanks to 历史学习 and real cycle times

- 更短 和 fewer 转换 thanks to the changeover matrix

- Improve timely execution of orders and on-time shipment

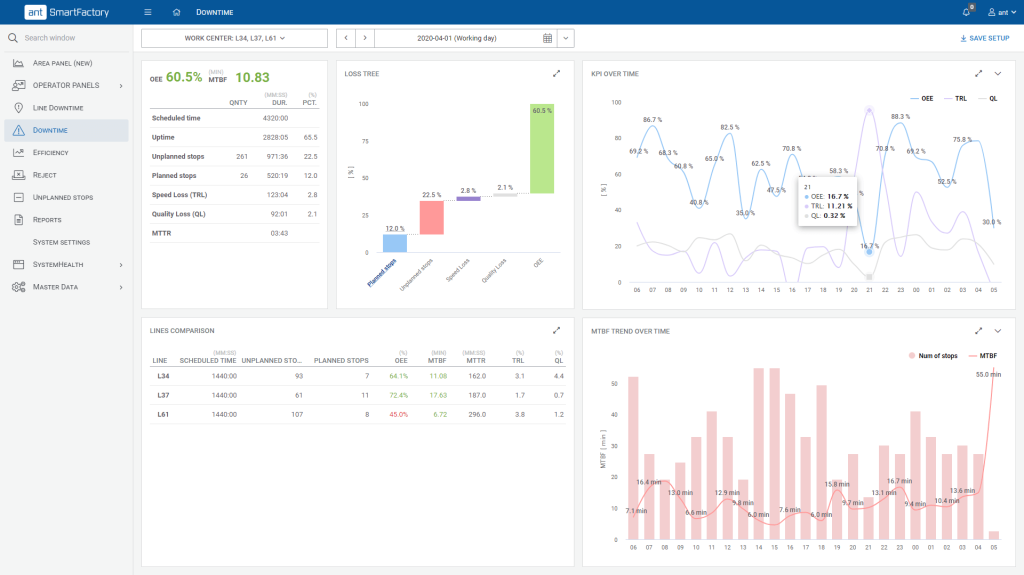

微停机监测

Features:

- Detect automatically each, even the shortest stop of the machine with its reason from PLC

- Do the deep 融合 与 遥控装置 to get even thousands of alarms and production data

- ǞǞǞ algorithm calculates the responsible machine and its root cause for line stop

效益:

- Get accurate, aggregated, real data to stop the stops

- Understand why the machines lose availability and have actual data to take actions

- Spend less time for manually reporting machine states

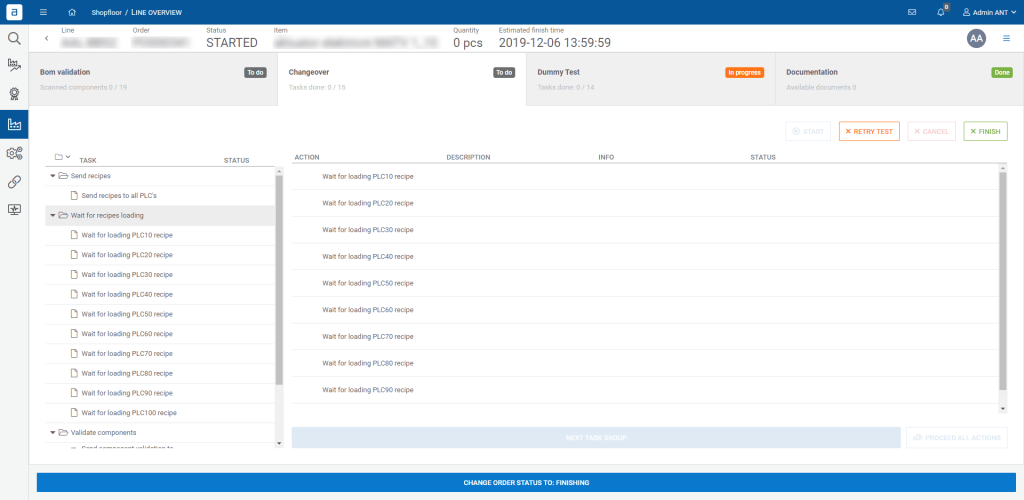

Features:

- Automatically send setpoints and programs to the machine’s PLC

- Control machine and send its PLC recipes

- Make automated changeovers on-the-fly

效益:

- Reduce changeover time significantly

- 消除 human errors by setting machine setpoints automatically

- Reduce time spent on management of recipe changes

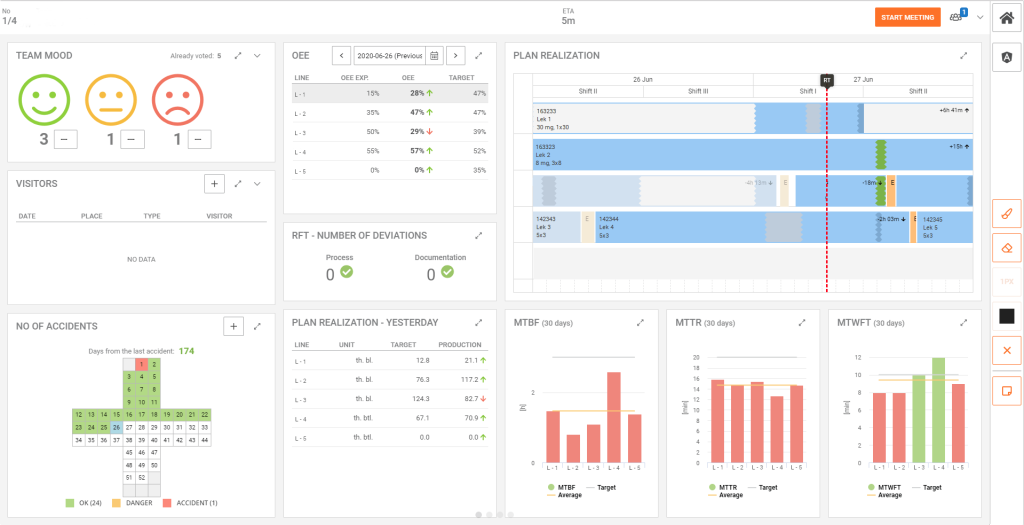

互动会议

Features:

- Organise a daily meeting with agenda and an 自动化 filled dashboard

- Generate charts automatically with real-time data feed

- Monitor team’s tasks and their progress

效益:

- Eliminate whiteboards from production with touchscreen

- Decrease time spent on 日常会议 和 shift changes

- Increase 员工 engagement through production transparency