With ANTs’ Traceability or track and trace, it is possible to keep track of the entire lifecycle of goods, from the moment they are obtained, produced, processed, stored, transported, consumed, to when they are disposed of. This ensures that businesses have full visibility and insight into the status of their goods at any time, allowing them to quickly identify any discrepancies or inefficiencies in their supply chain.

Why is Traceability important?

By monitoring food or automotive products from their origin to the point of sale, manufacturers can detect any contamination or fatigue issues in a timely manner. For example, if a product is found to be contaminated, a traceability system can help quickly identify the source of contamination, allowing manufacturers to take corrective measures to protect consumers from potential harm.

Additionally, traceability helps manufacturers ensure that the products they provide meet their customers’ quality expectations, as it allows them to track any changes in ingredients or processes that could affect the end-product.

Traceability can also help manufacturers reduce the risk of fraud, as they can easily determine the true origin of an item, rather than relying on fraudulent suppliers. This key module can also assist manufacturers in meeting their legal obligations, such as product labeling and traceability requirements set by regulatory bodies.

Your benefits with ANT Traceability

Preventing production errors

Preventing production errors: Traceability data offers the opportunity to learn from mistakes. Causes and circumstances that have already led to errors can be avoided in the future through process optimisation.

Material security

If there are concerns about the quality or integrity of raw materials,traceability checks can identify each individual product involved. Inspections and rework require little more effort.

Compliant production

Traceability enables the verification of appropriate production, including all data and materials related to internal processes.

Customer satisfaction

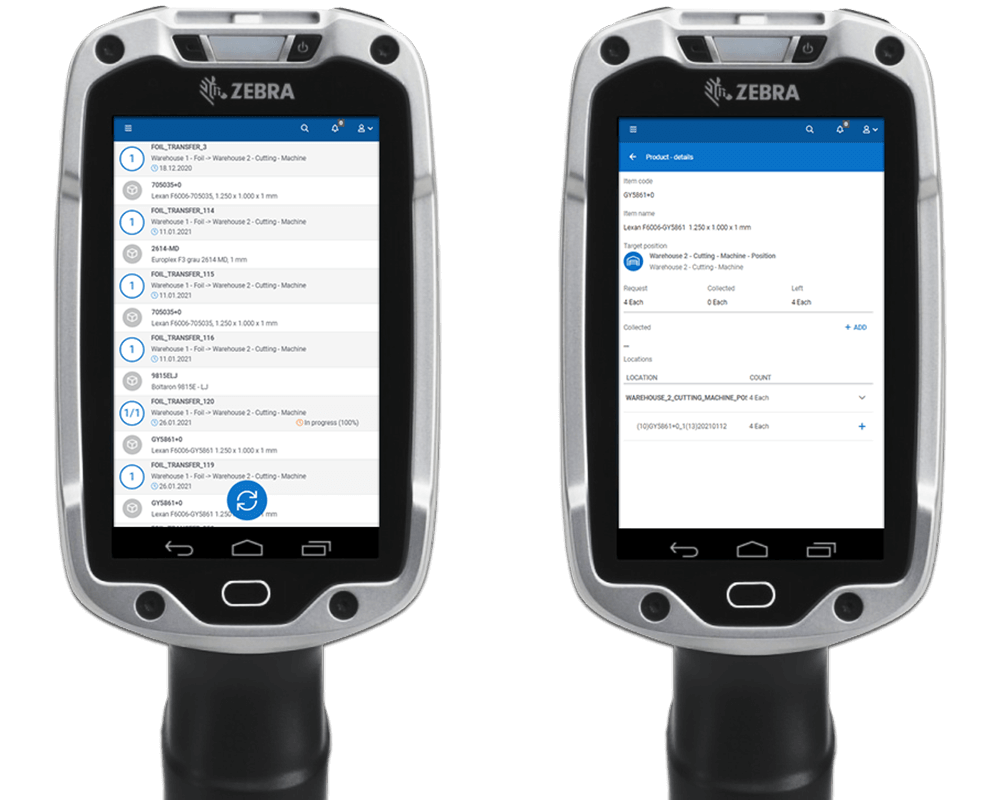

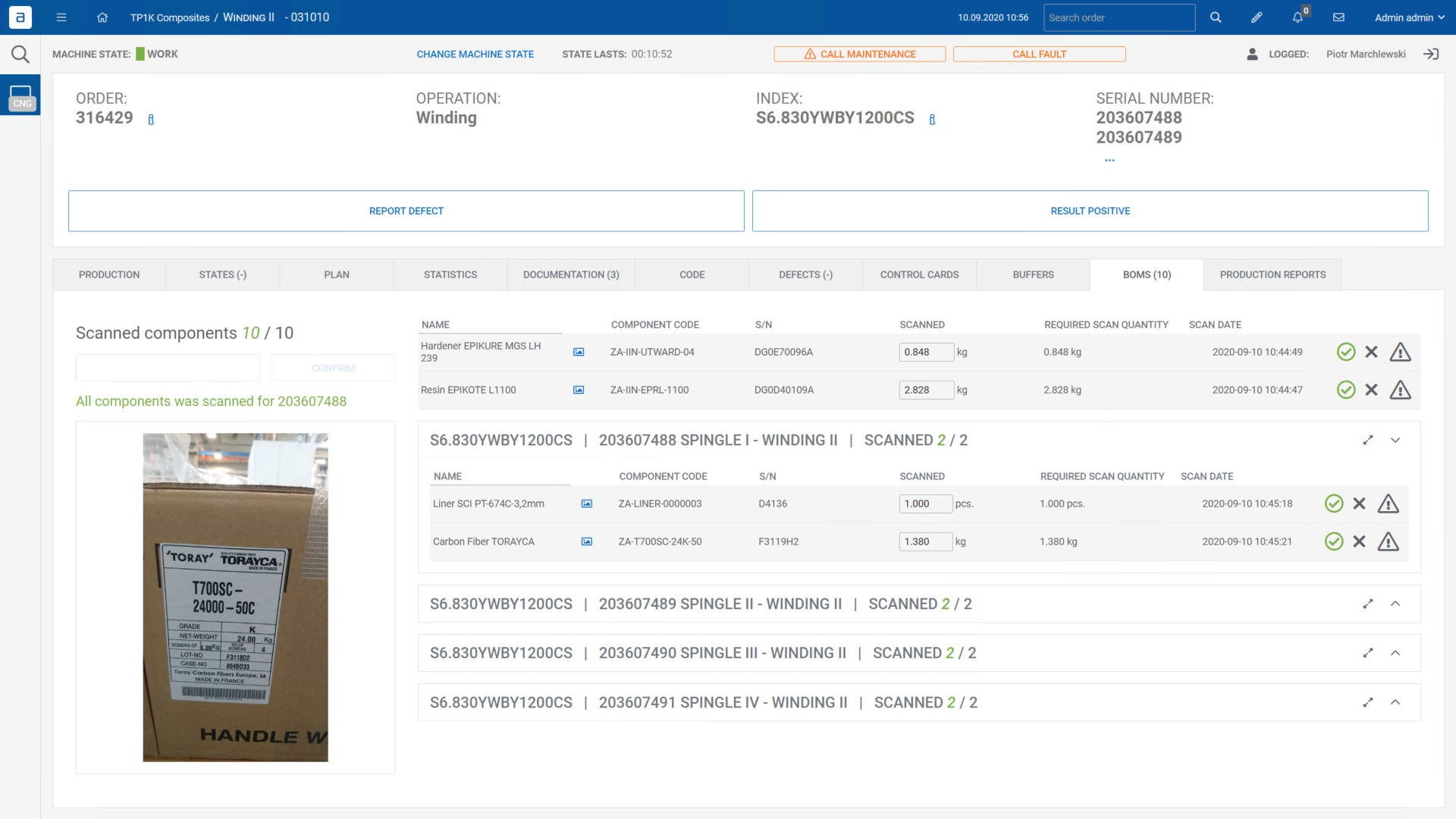

Describe the actions available and the consequences of activities in different contexts, such as handling operations in MES system, taking data from devices or human system mediation. Designed in Forms Builder.

How to ensure full Traceability with ANT?

What are Traceability Levels in Goods Manufacturing?

Traceability provides manufacturers with a high-level understanding of their processes, helping them make better decisions and remain compliant. With traceability, businesses can more easily identify and fix any issues that arise, as well as meet customer expectations and comply with industry regulations. It is also beneficial for improving production efficiency and product quality control, as it provides manufacturers with real-time visibility into their production systems.

For different industries, traceability requirements may vary, and some factories may require more complex systems than others. However, it is still important that all factories invest in a traceability system as it is essential for guaranteeing the highest quality and complying with all relevant laws and regulations. There is no need for some factories to invest heavily into the very complex system when only a simple approach is required by the law or manufacturing process to ensure high quality and compliance.

There are four main levels of traceability in goods manufacturing:

1.

Level 1 traceability is the minimum that should be expected for any manufacturer of good standing and requires that raw materials, components, and finished goods be documented and tracked

2.

Level 2 traceability requires the ability to track items within the production process, including the tracking of batches of materials, intermediate products, and finished goods

3.

Level 3 traceability requires the ability to track and trace each individual item, including components, raw materials, and finished goods

4.

Level 4 traceability requires the ability to track and trace each individual item and its history, including which parts were used to create it, how it was processed, and where it was shipped

What are key industries that will benefit from traceability module in their MES system?

What traps to look out for when implementing traceability in the factory?

Products related to this Article

MES System – Manufacturing Execution System – ANT Solutions

System MES – Manufacturing Execution System 0 % operating time increase 0 % defects quantity reduction 0 % material consumption reduction 0 % changeovers time

How to monitor and control automated assembly production line?

With the advent of Industry 4.0, broadly defined automation of production lines has become a standard, without which it is difficult to imagine a modern

13 business benefits with MES implementation

MES is now undoubtedly the basis of digitalization and the foundation of modern manufacturing activity. In the environment that can be described as Industry 4.0,