Conscious digitisation of production as a way to stay one step ahead of the competition

No one needs to be made aware of the importance of digitising production in order to create an Industry 4.0 factory. Rather than thinking about

Limit the implementation time thanks to our Industry Suites:

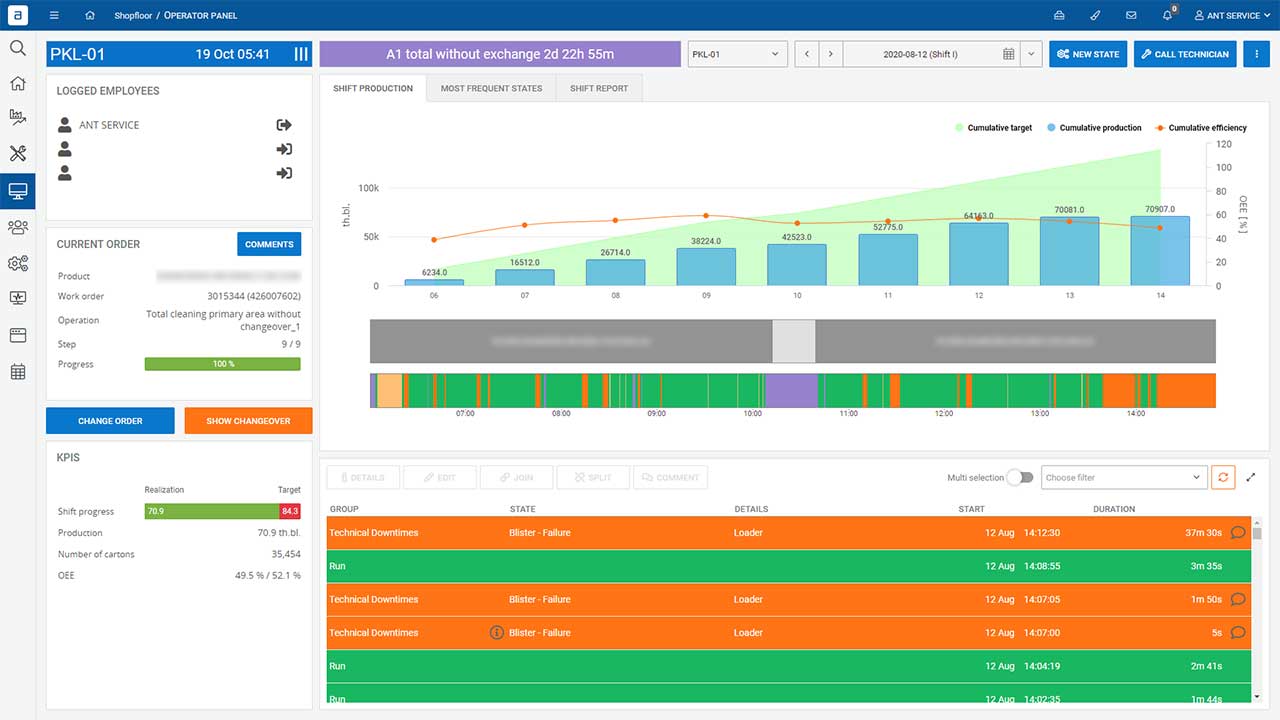

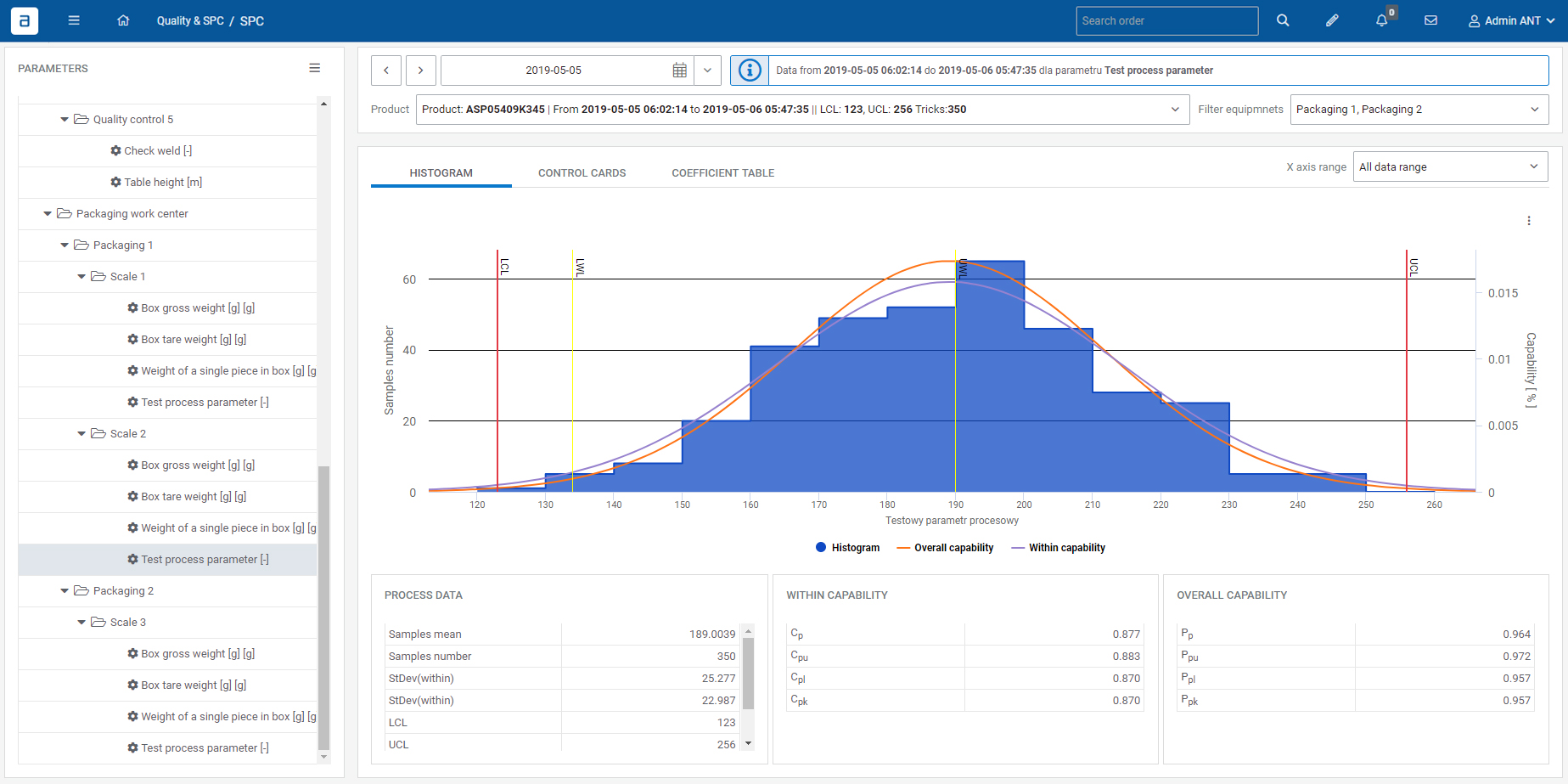

FMCG companies face frequent stoppages on the lines without the possibility to identify the root causes and bottlenecks. Needs for reduction direct production costs force factories to reduce material waste, reject and defects. We help them optimize both.

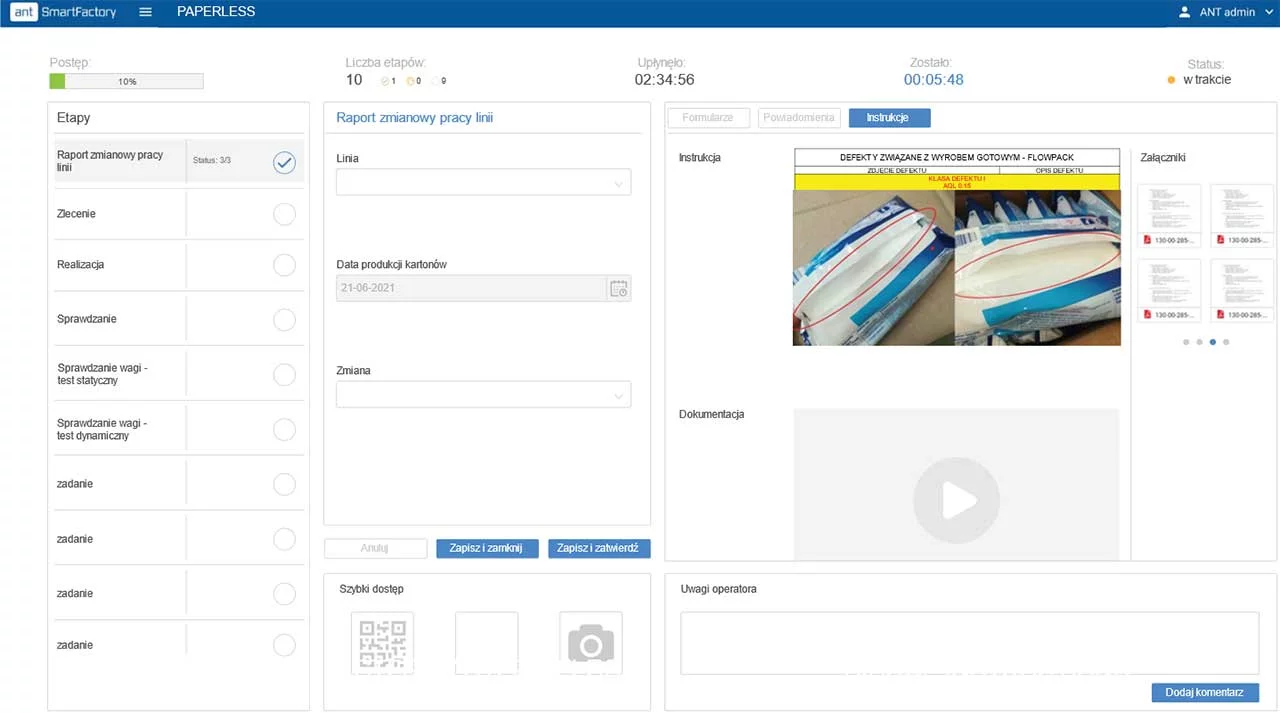

Pharma companies are looking for a reduction of the administrative time of Operators and ensure process compliance with GMP and GAMP. Factories miss automated data collection, online process control and operator guidance through the production steps based on workflow.

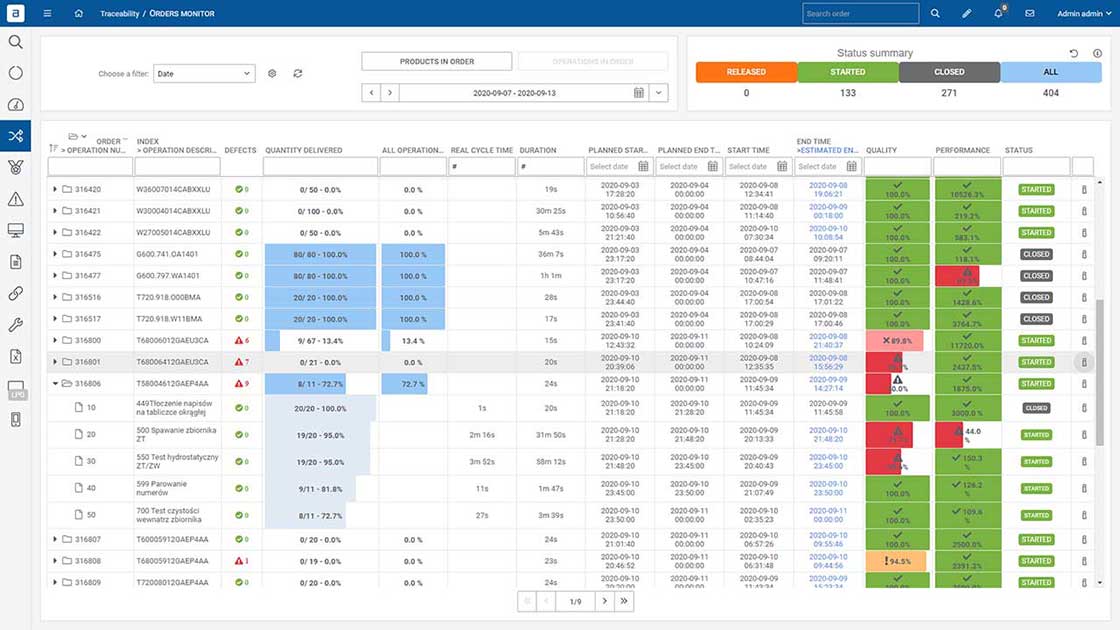

Automotive companies struggle with low availability and production performance. Market regulations require track&trace of used raw materials, components and tools together with their validation during the production.

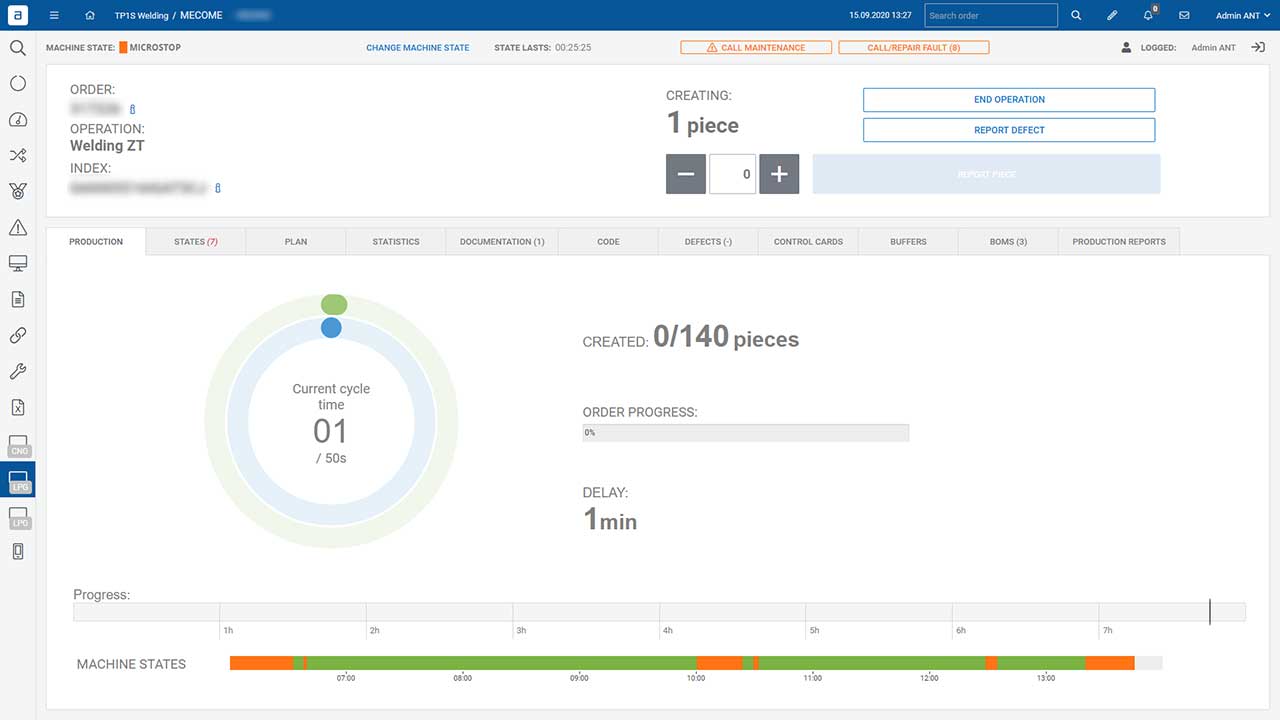

Manufacturing companies require to be more flexible and efficient. Without gathering data from machines, it is impossible to monitor production progress in real-time. The constantly growing quantity of products and orders impacts delayed shipments and the necessity for improving performance.

MES is a beneficial solution for the production of military equipment due to the provision of greater visibility of the progress of production orders and control over the entire production process. Implementing an MES allows monitoring and validation of materials, tracking of production operations and quality, and identification of areas for improvement.

No one needs to be made aware of the importance of digitising production in order to create an Industry 4.0 factory. Rather than thinking about

The implementation of a MES system is a complex and costly process that requires careful planning and preparation. A key step is to conduct a

Digitalization means that reporting in its traditional form, as we have known it for years – in paper form, symbolically passed from hand to hand

Download Return of Investment (ROI) Document in Molding Injection Machine Industry