ANT SMART FACTORY

One platform. Plenty of solutions for Manufacturing Operations Management

What We Do

ANT Solutions is a one-stop provider for your manufacturing improvement needs.

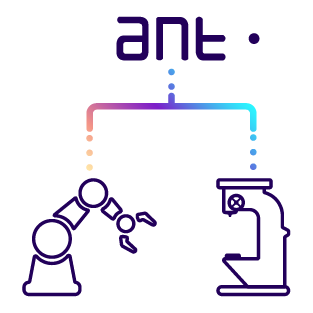

Machine

Connectivity

We collect signals from every possible machine on the market

Software

Development

You get an out-of-the-box modular system ready for major customization

Implementation

We provide the infrastructure and do all the heavy lifting

Continuous

Support

You get 24h/7 on demand support

Cloud Manufacturing

Unlock the Potential of Cloud Manufacturing: Increase Efficiency, Reduce Costs, and Enhance Product Quality. Choose between Cloud-Native and On-Premise Architecture

- Scalability

- Accessibility

- Agility and Flexibility

- Better Use of IT Resources

- Additional Cloud Services

- Improve Security

- High Availability

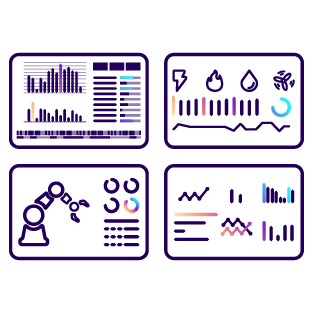

Continuous Improvement

Empower your solution with multiple extensions

Benefits for your production

65%

FASTER REACTION TIME

- • Real-time production data from machines

- • On-line notifications for production maintenance & quality

- • Production progress & quality online monitoring

90%

REDUCTION IN REPORTS GENERATION

- • Automatic data collection from the machines

- • Bi-directional interface with ERP

- • Digital guidance for Operators

15%

OEE INCREASE

- • Higher machines net run time

- • Microstops reduction

- • Less defects

Transform your production in 6 weeks!

We will implement the standard system in 6 weeks, thanks to out-of-the-box solution and proven implementation method

2023 Digitalisation Guide

- Learn what are the key steps to digitalise factory

- Identify key problems that occur during the production

- How software for factories fits industry 4.0 paradigms

- Why digitisation of production plants fails?

- What the MES price depends on?

- What human resources do I have to reallocate to the project?

Related articles

How to manage reworks in production?

Let’s be honest – the term “rework” is most commonly associated with delays in production. Technically speaking, rework means correcting failed, defective, non-conforming items. It

Generative AI in Manufacturing: First Steps in embracing AI in your factory

Generative AI and online chat assistant have become a new buzz words. Use AI OpenAI Assistants and OpenWidget to give your employees helpful assistant to

Manufacturing Data Collection – Connect Machines with Modern Production Software

In the evolving landscape of manufacturing, the integration of machine connectivity and modern production software stands as a cornerstone. It marks the confluence of real-time

New Data Act Proposed by EU. Revolution in Data Accessibility in Manufacturing Industry

The European Commission has proposed new rules on who can use and access data generated in the EU across all economic sectors, including manufacturing industry.

Why choose a single partner providing technology solutions for factories?

Implementing modern technological solutions in a factory involves carrying out numerous operations that determine the effectiveness of the finished software. The installation of equipment, implementation

Industry 4.0 challenges – Cloud or On-Premises?

In today’s world, many companies are stuck between whether to stay on-premises or go hybrid. The latter is almost always more difficult, but almost always