Erzielen Sie eine Reduzierung von bis zu 15%, rationalisieren Sie Ihre Prozesse und maximieren Sie Ihren Output.

Die mittlere Betriebsdauer zwischen zwei Ausfällen erhöht sich um 50%, so dass die Maschinen länger und härter arbeiten.

Reduzieren Sie die Einrichtungs- und Übergangszeiten um beeindruckende 20%.

GO PAPERLESS!

Entscheiden Sie sich für einen umweltfreundlicheren, effizienteren und weniger unübersichtlichen Arbeitsplatz mit unseren Funktionen zur Papierreduzierung.

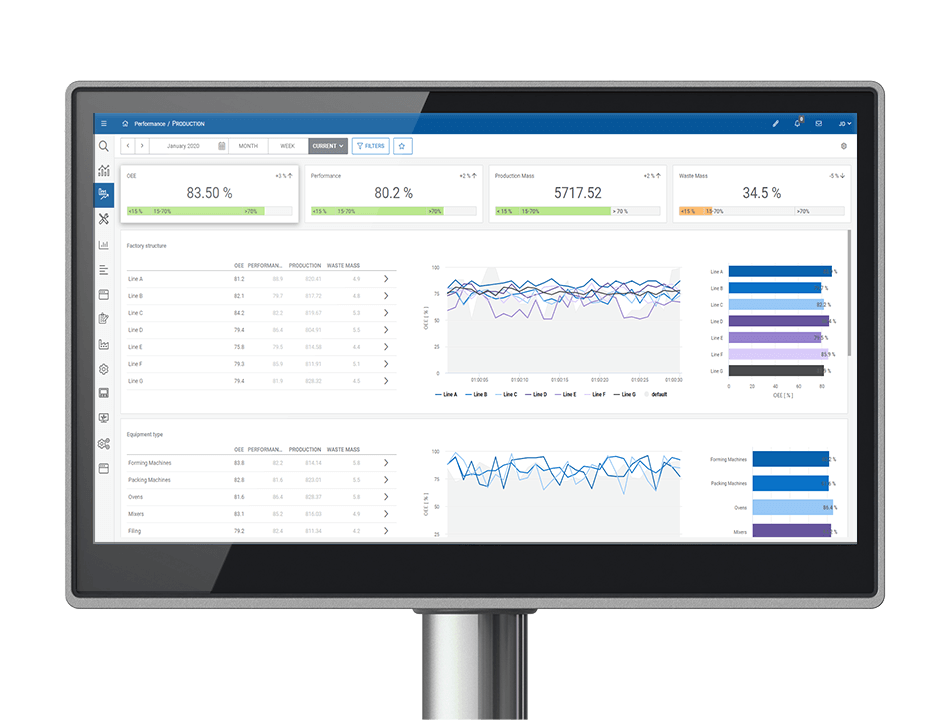

Nutzen Sie die Leistungsfähigkeit der Technologie und datengestützte Erkenntnisse, um Ihren Produktionsprozess zu optimieren. Unser MES-System ist vollgepackt mit Funktionen, die speziell auf die FMCG-Fertigung zugeschnitten sind und jeweils darauf abzielen, Ineffizienzen zu beseitigen, die Produktivität zu steigern und unnötige Stillstandszeiten zu reduzieren.

Maschinen-

Konnektivität

Die nahtlose Maschinenintegration gewährleistet Datenerfassung und -analyse in Echtzeit.

Operator Panel mit Micro Stops Überwachung

Die intuitive Benutzeroberfläche macht die Überwachung von Ausfallzeiten zu einem Kinderspiel.

Mikro-Stopps und

OEE-Überwachung

Vertiefen Sie sich in die Gesamteffektivität der Ausrüstung und konzentrieren Sie sich dabei besonders auf die Mikro-Stopps.

Traceability

Vom Scannen der Komponenten bis hin zu den Chargenprotokollen sorgen Sie bei jedem Schritt für absolute Transparenz und Gültigkeit.

Umrüstungen, SMEJ, Reinigen Prüfen Schmieren

Verbesserte Übergangsverfahren sorgen dafür, dass die Maschine jederzeit einsatzbereit ist.

Papierlose Umgebung

Gehen Sie mit weniger Papierkram in die Zukunft und sorgen Sie für Effizienz und Umweltverantwortung.

Ob Zucker, Kekse, Mehl, Joghurt oder Nudeln - unser MES-System ist auf die vielfältigen Bedürfnisse der FMCG-Branche zugeschnitten. Steigern Sie die Effizienz, reduzieren Sie die Verschwendung und steigern Sie die Produktivität auf der ganzen Linie.

Investieren Sie in die Zukunft der FMCG-Herstellung. Rüsten Sie Ihr Unternehmen mit einem System aus, das die Feinheiten der Mikrostopps wirklich versteht und berücksichtigt. Wenden Sie sich noch heute an uns und setzen Sie die Zahnräder des Fortschritts in Bewegung.

Zuverlässige Berichterstattung, Einblicke in die aggregierten Ergebnisse, taktischer Einsatz für die schichtweise/wöchentliche Priorisierung nach Schadenskategorien. 100% Flexibilität bei der Berücksichtigung der KPI-Standards des Benutzers, gutes Verständnis der KPIs der schlanken Produktion

Tonci M., Global Manufacturing Systems Manager bei BAT

Dank des MES-Systems sind wir in der Lage, die aktuelle Produktionssituation zu verfolgen und Informationen über Fehler und potenzielle Risiken zu erhalten - alle Informationen können in eine KPI-Tabelle umgerechnet werden, die einen Managementprozess unterstützt.

Verifizierter Rezensent von Capterra., Digilal Projektleiter bei Lebensmittel und Getränke

ANT sp. z o.o.

Al. Pokoju 18

31-564 Kraków, Polen

VAT ID: PL6792888061

+48 12 296 50 40

ANT Solutions bietet digitale Lösungen für Fertigungsunternehmen.

Website: ANT-Lösungen

Klicken Sie auf die Schaltfläche ➞

Indem Sie Ihre E-Mail-Adresse angeben und auf die Schaltfläche "Katalog herunterladen" klicken, stimmen Sie dem Erhalt unseres Newsletters zu.