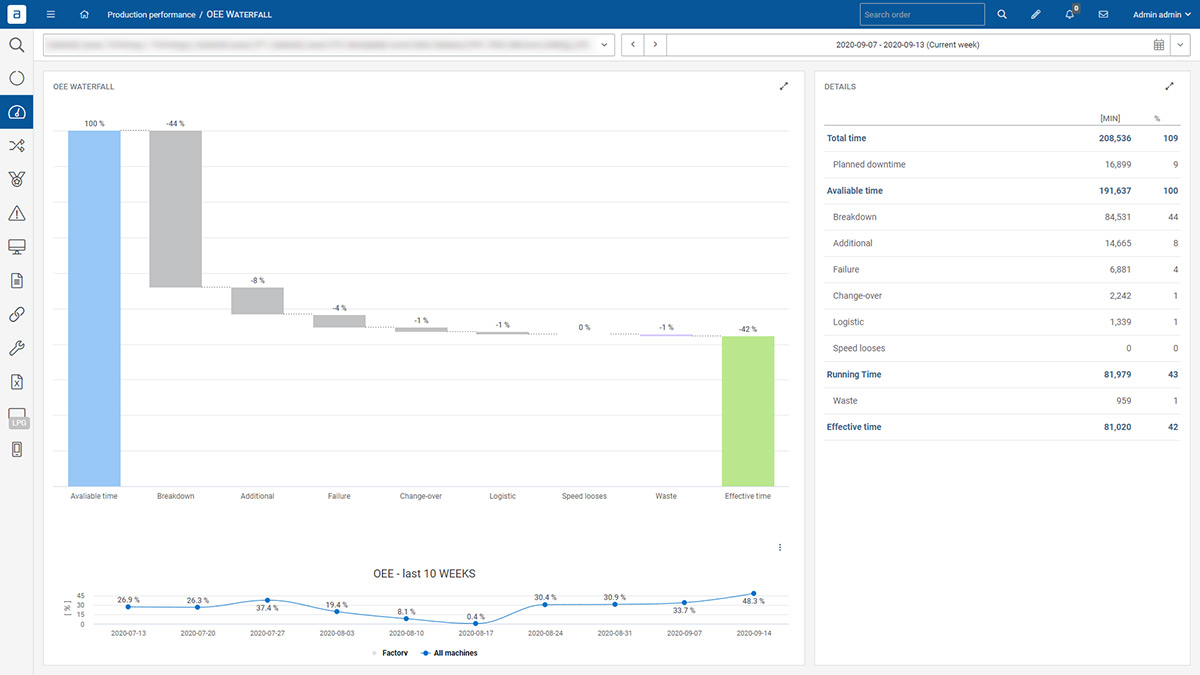

- Overall Equipment Effectiveness (OEE) is low due to one or more of the following factors: availability, performance, and quality.

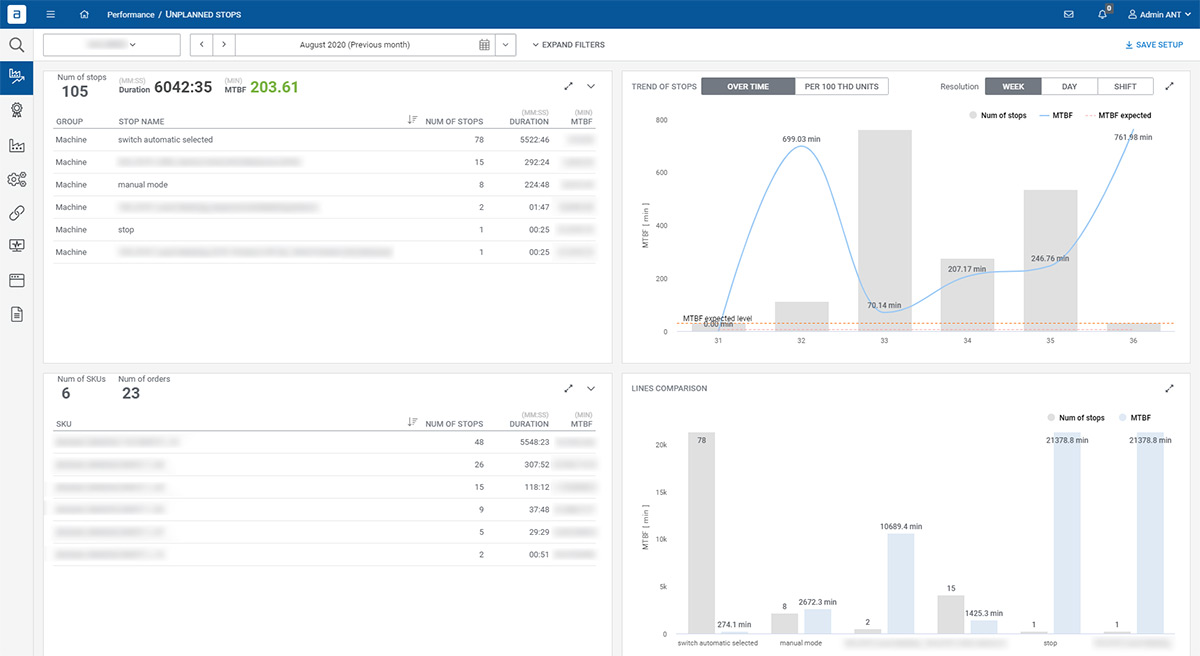

- Availability may be low due to unplanned downtime, downtime duration, and lack of improvement in KPIs. Unplanned downtime can be caused by reactive maintenance, failing to gather information about downtime, slow reaction times by maintenance services, and lack of updated information.

- Unplanned downtime: This can be caused by equipment failures, power outages, and other disruptions. Unplanned downtime is a major contributor to low OEE because it reduces the amount of time that the equipment is available to produce good products.

The OEE is the result of three factors, these being availability, performance, and quality. It’s no secret that improving just one of the factors immediately increases the value of the OEE and therefore brings about benefits for the business in its entirety. In the manufacturing sector achieving optimum results across all three areas is key to operating a successful line since they all individually contribute to the viability of the product or service and the profitability.

Verfügbarkeit – um die Zeit besser zunutzen

This factor essentially encompasses any events that have the potential to bring any planned production to a halt for a sustained time. Though downtime is a necessity in the manufacturing industry, it should be kept to a minimum to minimize losses and ensure maximum productivity. There are three main ways that this can impact the overall OEE.

1. Zu viele ungeplante Ausfallzeiten

This is often due to reactive maintenance. However, failing to gather information about the real reasons for downtime can also prevent improvements from being made in this regard.

2. Downtime that drags on for a sustained period

Langsame Reaktionszeiten der Wartungsdienste, manuelle Wartungsaufrufe, fehlende Erfassung der Betriebshistorie der Maschinen oder ein Mangel an aktuellen Informationen gehören zu den Hauptgründen dafür.

3. Keine Messung und Verbesserung der KPIs".

MTTR (mean time to recovery), MTBF (mean time between failure), and MTTF (mean time to failure) all have a part to play in both measuring and improving key performance indicators.

ANT’s endorsed approach to availability is the Andon maintenance module. The Andon maintenance module seeks to reduce such issues by compiling the history of repair reports and using the most recent failures as hints, measuring maintenance reaction times, providing relevant maintenance services along with the causes of downtime, and taking KPI measurements (MMTR, MTBF, MTTF) regularly.

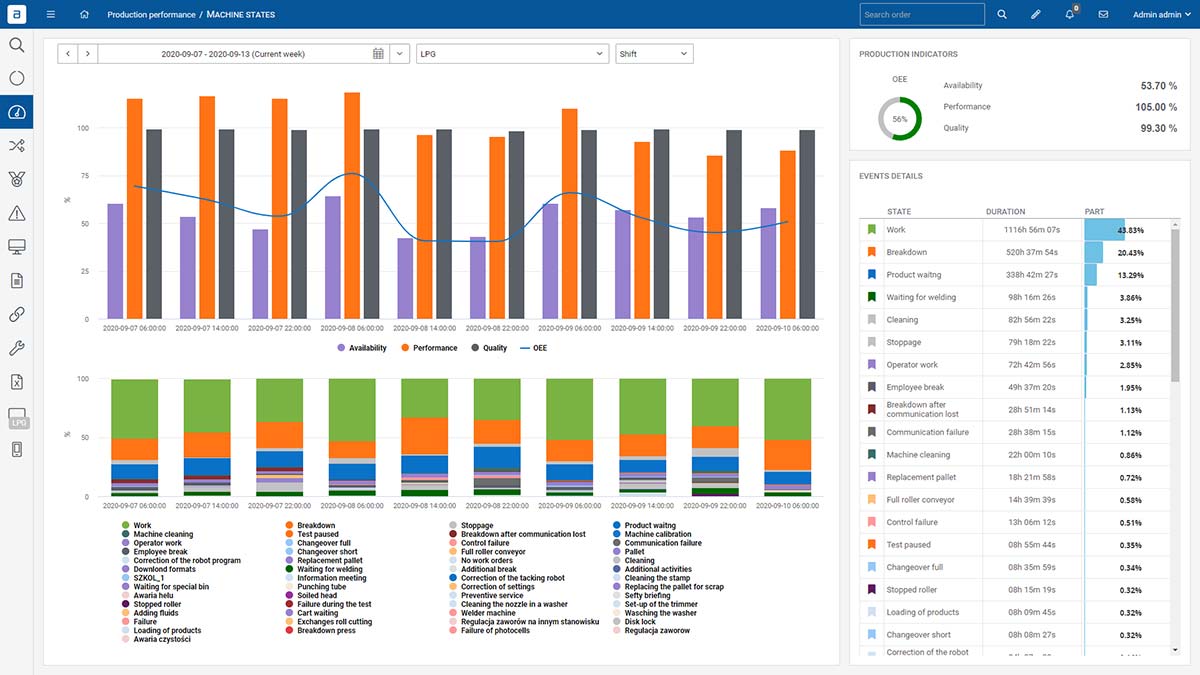

Leistung – Potenzielle Schwachstellen erkennen

The performance takes into account anything that causes the manufacturing process to run at less than the maximum possible speed when it is running (including both Slow Cycles and Small Stops).

However, it’s important to highlight that this particular factor is not associated with units produced, but rather with the equipment or technology used to run the manufacturing line itself. Here, adjustments can be made to boost the efficiency and capability of the line in question.

4. Langsamer Zyklus

Dies hängt in der Regel mit einer mangelnden Überwachung der tatsächlichen Zykluszeiten, einer fehlenden Automatisierung, einer mangelnden Aufgabenplanung oder zu vielen Mikrostopps in einem bestimmten Zeitrahmen zusammen.

5. Langer Produktionsstart

Multiple changeovers are among the most common culprits in these cases, although manual communication with laboratories or quality control departments can also impact production launches.

6. Mangelnde Schulung des Bedienpersonals

Dies kann auf fehlende digitale Schritt-für-Schritt-Anleitungen für die Bediener, zu lange Einarbeitungszeiten oder mangelnde Transparenz in Bezug auf Produktion und Produktionsziele zurückzuführen sein.

To combat these three reasons for limited performance, ANT has created Digital Documentation and Paperless modules. These enable you and your manufacturing team to display digital information to the operators, categorize documentation such as changeovers and quality controls, guide operators through production and changeovers using step-by-step activities, and automate communication with the laboratory.

It is hoped that this tool will enable you to make your line more efficient and, as a result, boost your overall productivity. Although it may seem cliché, it’s often true that the key is in the finer details, and although a micro stop may seem insignificant, a micro stop module is designed to open your eyes to their potential impact.

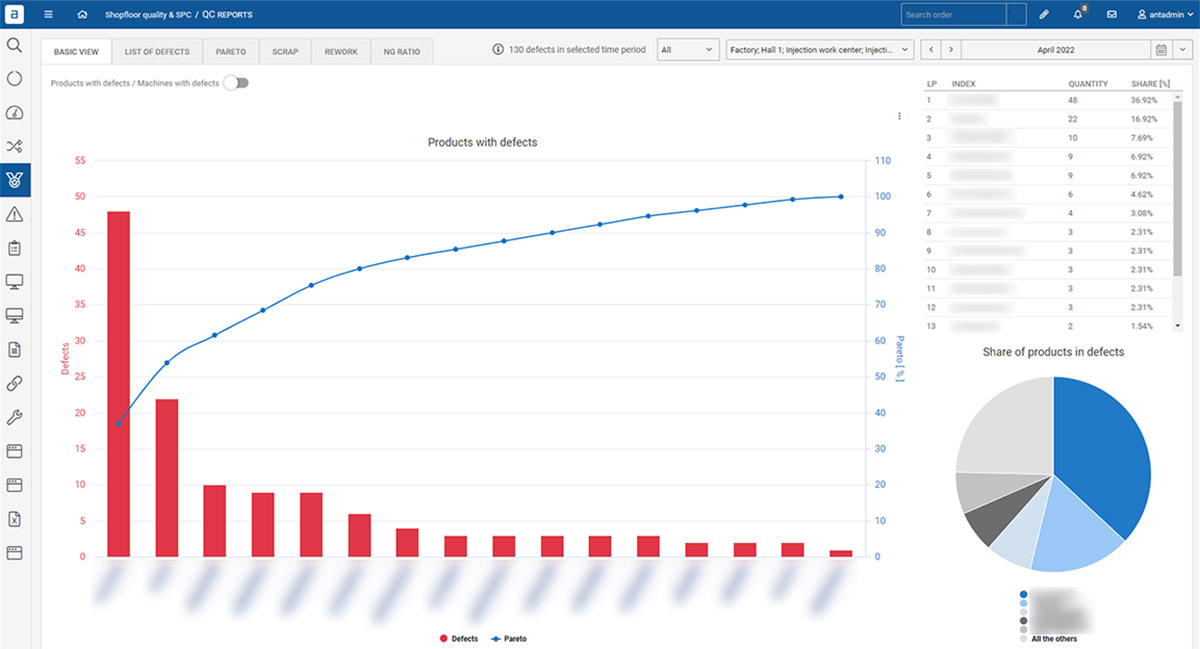

Quality – Inspektion der Details aus nächster Nähe

Qualität berücksichtigt hergestellte Teile, zusätzlich derer, die nicht den Qualitätsstandards entsprechen und Teile, die nachgearbeitet werden müssen. Es ist also ein Mittel um die Ausbringung der Linie zu messen und wie diese durch Defekte oder Modifikationen beeinflusst wird.

7. Zu viele Mängel

A lack of analysis in defect production stands out as the most common cause, although cyclic activity lists for operators can also influence the number of defects detected.

8. Keine Validierung der verwendeten Materialien/Werkzeuge/Prozessparameter vor Beginn der Produktion

Cross-checks with used materials batches in the ERP system used material codes in BOM lists are essential in this case, however, it is also crucial to ensure that the machine setpoints (recipes) are correct (manually by the Operator or automatically by ANT system & PLC)

9. LErkennung eines instabilen Prozesses

This is commonly associated with a Lack of SPC diagrams & control charts & condition-based monitoring. That said, failure to implement automatic counting of how many cycles the tool has made (tool life cycle monitoring and regeneration plan) can also influence late recognition.

ANT seeks to remedy these issues through the launch of its Quality Inspections module, which helps operators and other line management staff to make more informed decisions, by providing them with automated feedback and detailed instructions. The module is also capable of producing a series of quality reports covering specific aspects such as defects.

Allgemeine Gründe, die OEE beeinflussen

10. OEE-Gleichung

It’s worth bearing in mind that the use of manual calculation methods is often inefficient, many companies also tackle the OEE calculation rather unobjectively or simply fail to implement it altogether

11. No tools and no plan for what to improve

A lack of tools to compare shifts, operators, machines, lines, and items, no clear method that determines how the gathered data should be used, or a lack of trend analysis also leads to issues in terms of production efficiency.

12. Unzuverlässige Daten

Dies ist ein weiterer Feind der Produktionseffizienz, der häufig durch das Beharren auf der Verwendung von Papierdokumenten, Verzögerungen bei der Übermittlung von Informationen und der maschinellen Datenerfassung in Echtzeit verursacht wird.

Of course, not all the reasons for low OEE can be attributed to these three main factors. However, our real-time notifications can help to minimize the impact of any issues that you may experience. Our system is also customizable so you can calculate your OEE in a way that works for your business, as opposed to using a standard, one-size-fits-all program.

The real value of OEE can’t be underestimated in manufacturing processes and improving quality, availability, and performance is essential, as difficult as it may seem. The way forward is to make decisions based on numbers instead of personal opinions.

Wenn Sie weitere Unterstützung bei der Messung und Verbesserung der OEE Ihres Unternehmens benötigen, dann wenden Sie sich an uns! Gerne besprechen wir, welche Module für Ihre spezifischen Bedürfnisse und Anforderungen am besten geeignet sind.

Key Takeaways:

- Master the three pillars of OEE: Minimize downtime, optimize production speed, and minimize defects.

- Embrace data-driven decision-making: Leverage automated data collection and analysis to gain valuable insights and continuously improve OEE.

- Move beyond manual calculations: Utilize automated methods for accurate and efficient OEE calculation.

- Achieve superior operational performance: By implementing these strategies, manufacturers can significantly enhance OEE and gain a competitive edge.

Produkte in diesem Artikel

MES-System - Fertigungsausführungssystem - ANT-Lösungen

System MES - Manufacturing Execution System 0 % Betriebszeitsteigerung 0 % Fehlermengenreduzierung 0 % Materialverbrauchsreduzierung 0 % Umrüstzeit

Überwachung von Mikrostopps

MIcro stopsmonitoring Das effektivste System für FMCG zur Überwachung von Produktionsraten und Ausfallzeiten Termin für eine Demo Was sind Microstops und warum sind sie so

OEE Leistungsüberwachung

Leistungsüberwachung (OEE) Verbinden Sie sich und sammeln Sie Daten von Ihren Maschinen. Planen Sie eine Demo Sie haben uns vertraut: Hauptvorteile OEE-Steigerung ✔️ kürzere Stillstandszeiten ✔️ schnellere Produktion