Machine Control

Take full control over your machine park

Machine Supervision System –

make production more effective, automatically!

Controlling production processes is necessary to guarantee a high-quality finished product. However, in the industrial sector, control at the end of the process is insufficient. Why? Preparing one product involves many of the process. At each of these stages, something may happen that will negatively affect the quality of the semi-finished product. Therefore, to make the process of control more effective, modern factories are deciding to implement advanced software designed for supporting all manufacturing processes and verifying their correctness step by step.

How does Machine Control Systems work?

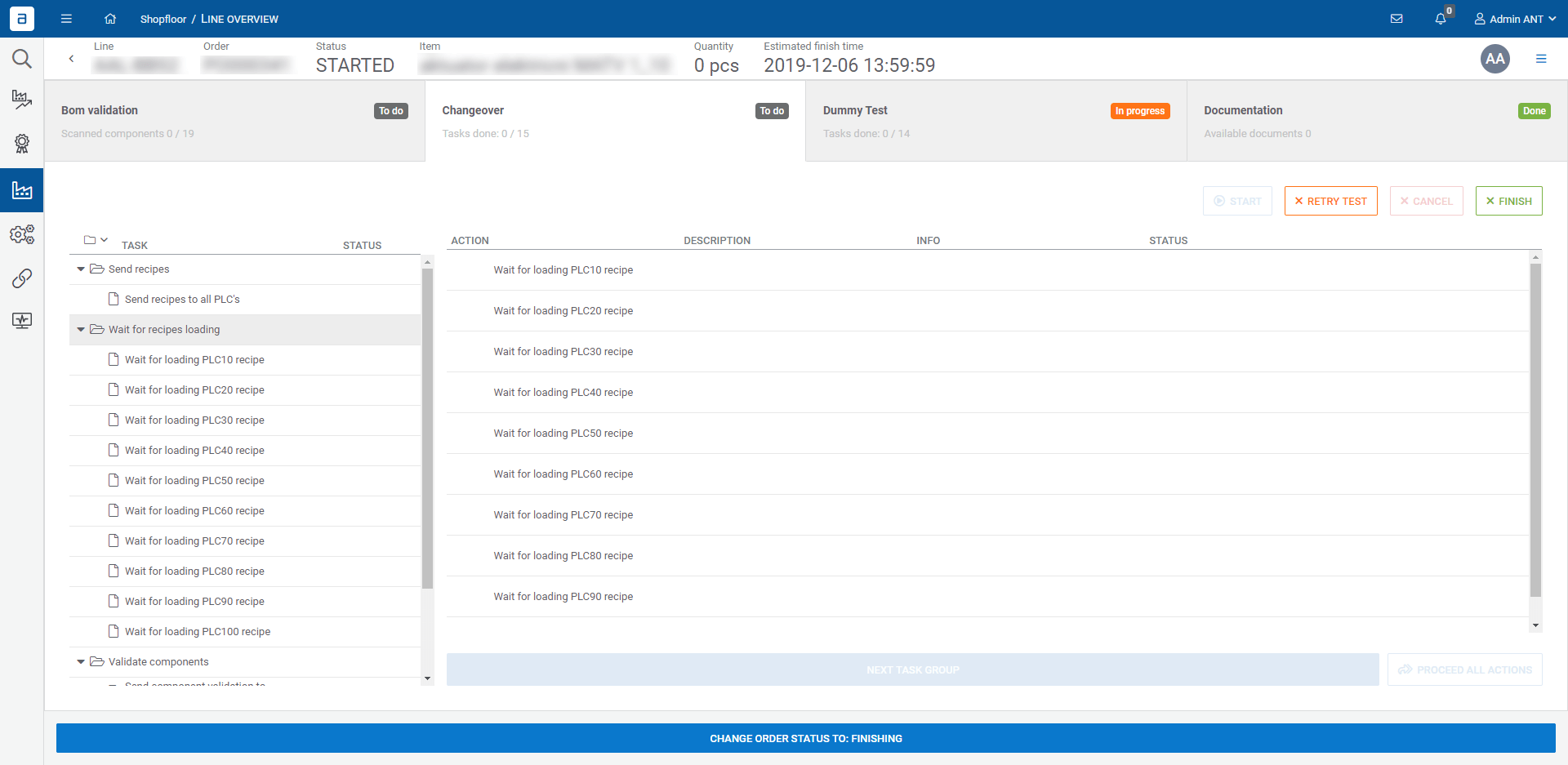

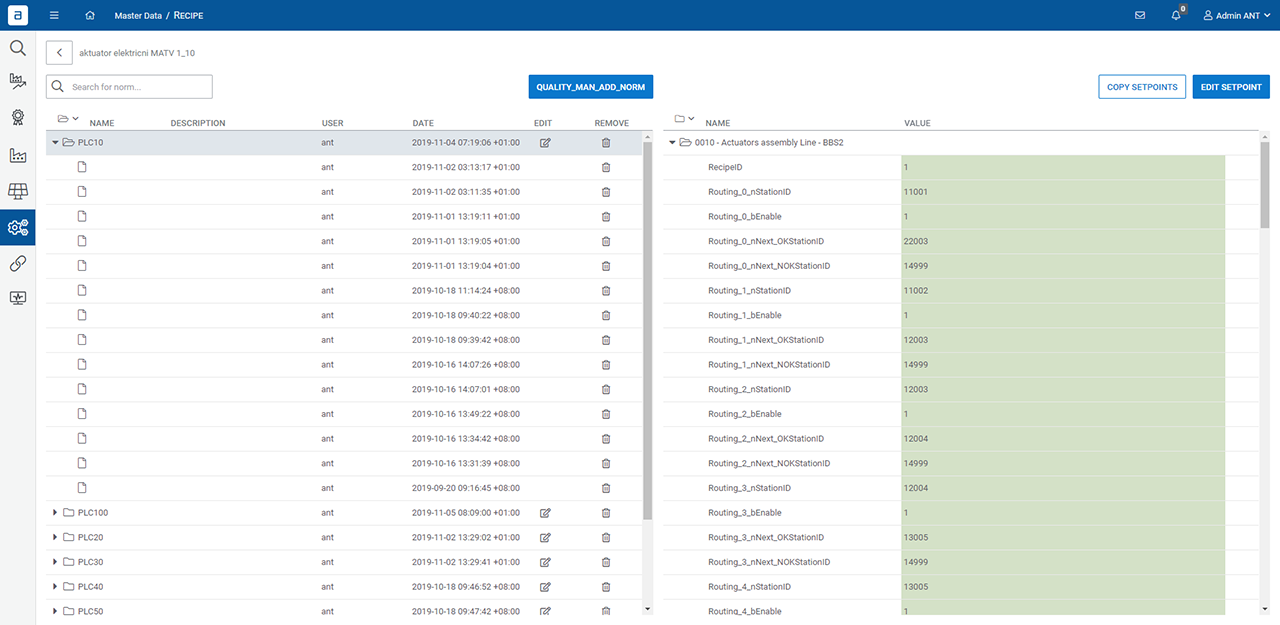

Machine Control is a system dedicated to automated production lines which cooperates with all connected machines, ensuring constant control of each process. The integrated software is gathering information about the actual status of a product by PLC and based on this data decides on the next operation and workstation. How does the system know where to direct a product? It is possible owing to the implemented routing.

This is the biggest advantage of dedicated software – programs, recipes, parameters, and a number of other process data are exchanged with the machine automatically. In this way, the software is supporting the operator activity and speeds up production time.

Key Features

Automatic and remote

set machine’s setpoints

Controlling machine and sending

to its PLC recipes

Fully automated changeovers

done on-the-fly

What features does the software offer to modern companies?

Controlling processes is one of the most crucial tasks for the production line management software. But it is not just about checking. The advanced control system includes functionalities that significantly improve production.

Machine Control is dedicated to automatically uploading:

- programs

- recipes

- set-points

The main goal of production is to provide a high-quality product according to plan and technology. The settings are prepared for each process and each product. It is an infinite amount of data that manually entering is a human error risk. It could cause failures and defective products.

Machine Control is automatically sending relevant data to machines allows for decreased changeover and production launching time. For example, the software is using data from Recipe Manager – a component responsible for preparing, modifying, and tracking changes to recipes, allowing for having full control over machine settings.

Quickly data exchange and real-time process tracking are the most important feature of Machine Control software. Collected data are analyzed up to date. Comparing achieving results of product parameters with a target value allow for categorizing the product as OK (meet the standards) or NOK (does not meet the standards).

Machine Control – chance to change for better

The development of modern industrial plants is possible thanks to meeting demanding standards. Production processes have to be faster and faster and at the same time have to generate products of better quality based on assumed technology. Factories also strive to eliminate defects and pay more attention to ecological aspects, for example by paperless production. Therefore, raising an enterprise to a higher level requires taking many actions. Most of them are guaranteed thanks to the implementation of our system. For example, our dedicated paperless module perfectly fits in green manufacturing culture by reducing paper on the shopfloor to a minimum.

Real-time data collection and analysis and automatic programming processes settings significantly reduce machine setup and changeover time. Using proven data and analyzing them in real-time and comparing it with historical data allows for early detection and prevention of faults. This action significantly reduces downtime.

The Machine Control Systems also support operators on the production processes step by step. Advanced software is sending important messages and instructions directly to the main operator panel. Again, we gain precious seconds and eliminate human error. This solution means that the operator fast receives all the data, and can implement changes just as quickly to adjust the current production status to the assumed plan.

One of the most important benefits of utilizing our software and its functions is an OEE increase. All these actions allow maximizing production line availability, performance, and quality.

Key Benefits

Significant time reduction

for changeover

Certainty to set machine setpoints

without any human error nor delay

Easier to manage changes in technology

and react remotely in real-time

Related articles

How to gather data for SPC report – automatic and manual measurements?

SPC, or statistical process control, is one of the most interesting tools in the context of quality management. Nowadays, this method is widely used

Electronic Batch Record – Automation and Paper Elimination in Pharma

It’s no secret that every step of the pharmaceutical manufacturing process must be documented. However, managing paper documentation can be extremely time-consuming for pharmaceutical manufacturers,

How to monitor and control automated assembly production line?

With the advent of Industry 4.0, broadly defined automation of production lines has become a standard, without which it is difficult to imagine a modern

Machine Control is a system that automates the operation of machinery. It is a type of industrial automation. Automation often involves the use of machine control to perform some task, such as controlling the speed or feed rate on a machine tool, or controlling an assembly line process.

The main objective of machine control is to provide safe and efficient production processes by automatically performing tasks that would otherwise be done manually such as uploading programs, set-points or recipes.

PLC drivers are a type of software that is used to connect machines to the computer for data aggregation. It is a type of middleware. This software is designed to work with a variety of machine types, such as CNC machines, robotic arms and more. The drivers are typically embedded in the machine controller and can be accessed from a PC or laptop.

The PLC drivers allow the user to monitor and control the production process by collecting data from sensors on the machine or by reading data off of an attached barcode reader, camera or other sensor. The data collected can be used for monitoring purposes and for predictive maintenance.